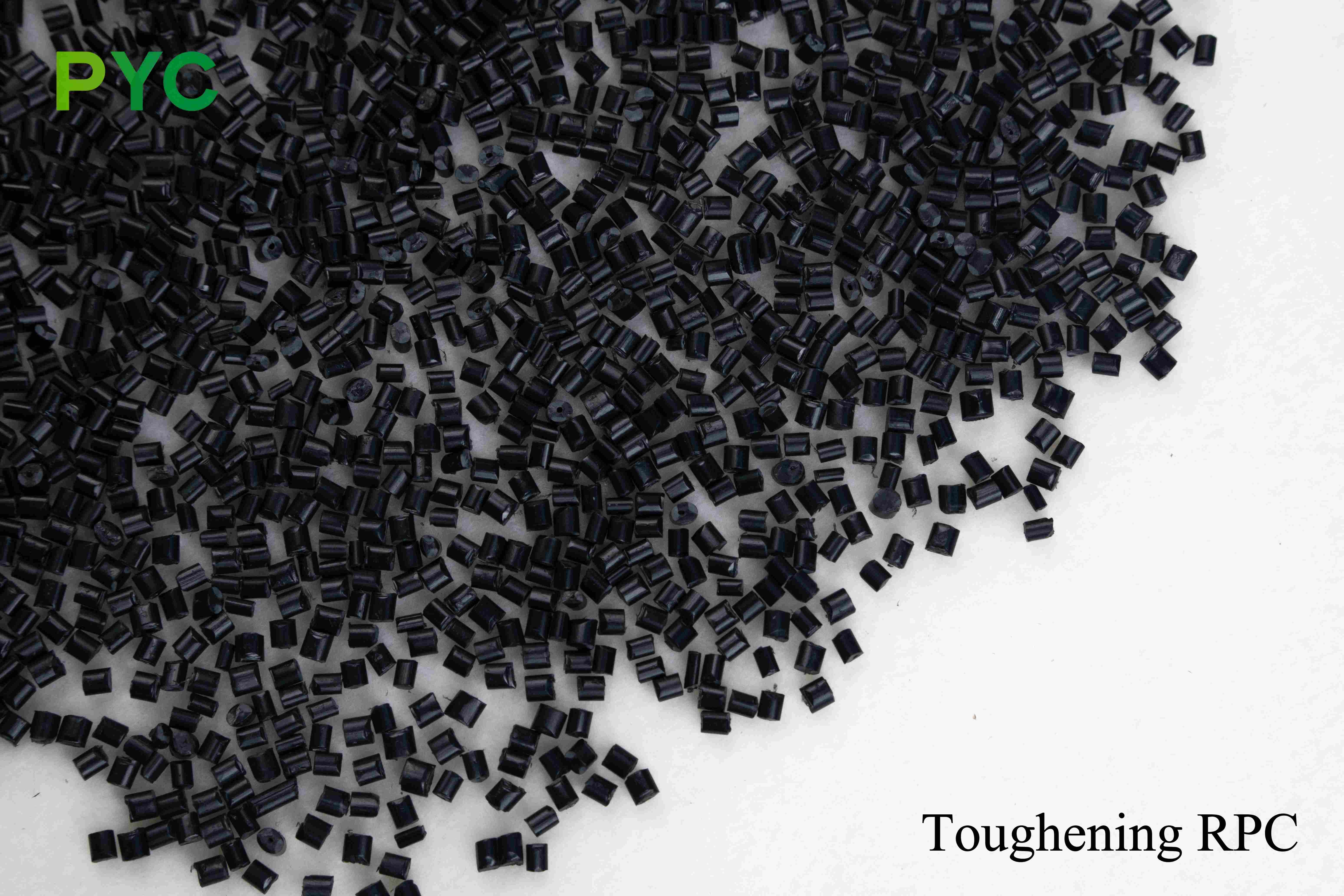

Toughening RPC

High quality recycled raw materials

Toughening RPC uses a single source, carefully screened recycled polycarbonate (PC) as a base material, mainly from high-quality recycled sources such as electronic waste, automotive parts, etc. The raw material is sourced from highly screened upstream manufacturers to ensure its low impurity content and high stability to ensure the high toughness, physical properties and color uniformity of the final product.

Select Recycling Sources

E-waste

PC parts derived from discarded electronics, such as smartphone cases, laptop cases, etc.

This electronic waste is carefully screened to ensure that it is free of impurities and suitable for the production of high quality Toughening RPCS.

Auto Parts

Derived from PC parts used in automobiles, such as lamp housings, dashboards, interior trim pieces, etc.

The material stability of automotive components is high, and recycling ensures that Toughening RPC has good impact resistance and durability.

Industrial Waste

Includes PC scraps and scrap produced in the industrial production process, screened and cleaned to ensure low impurities and stable physical properties.

All raw materials are carefully screened, treated and tested to ensure that Toughening RPC products have outstanding toughness, impact resistance and excellent mechanical properties for applications requiring high durability. Strict quality control

Toughening RPC is modified with polymer toughening technology to significantly improve impact strength and low temperature resistance. Each batch of Toughening RPC is thoroughly tested to ensure that it meets strict standards in terms of physical properties, impact resistance and chemical resistance to meet the high performance needs of different industries.

Toughening RPC is made from high-performance recycled polycarbonate (RPC) with special toughening modification technology to improve the material's impact strength and durability. Toughening RPC maintains excellent mechanical properties and avoids cracking even at low temperatures, making it ideal for applications with high impact requirements, such as automotive parts, safety protection equipment, and sports equipment.

The material not only has excellent weather resistance and UV resistance, but also maintains dimensional stability and mechanical properties during long-term use. Its excellent chemical corrosion resistance makes it widely used in industrial equipment housing, power tool housing and electronic and electrical fields. In addition, Toughening RPC is compatible with injection molding, extrusion, thermoforming and other processing methods to adapt to different production needs, improve manufacturing efficiency and reduce production costs.

REACH and RoHS certified products ensure environmental compliance and provide customers with high-strength, impact-resistant sustainable RPC solutions.