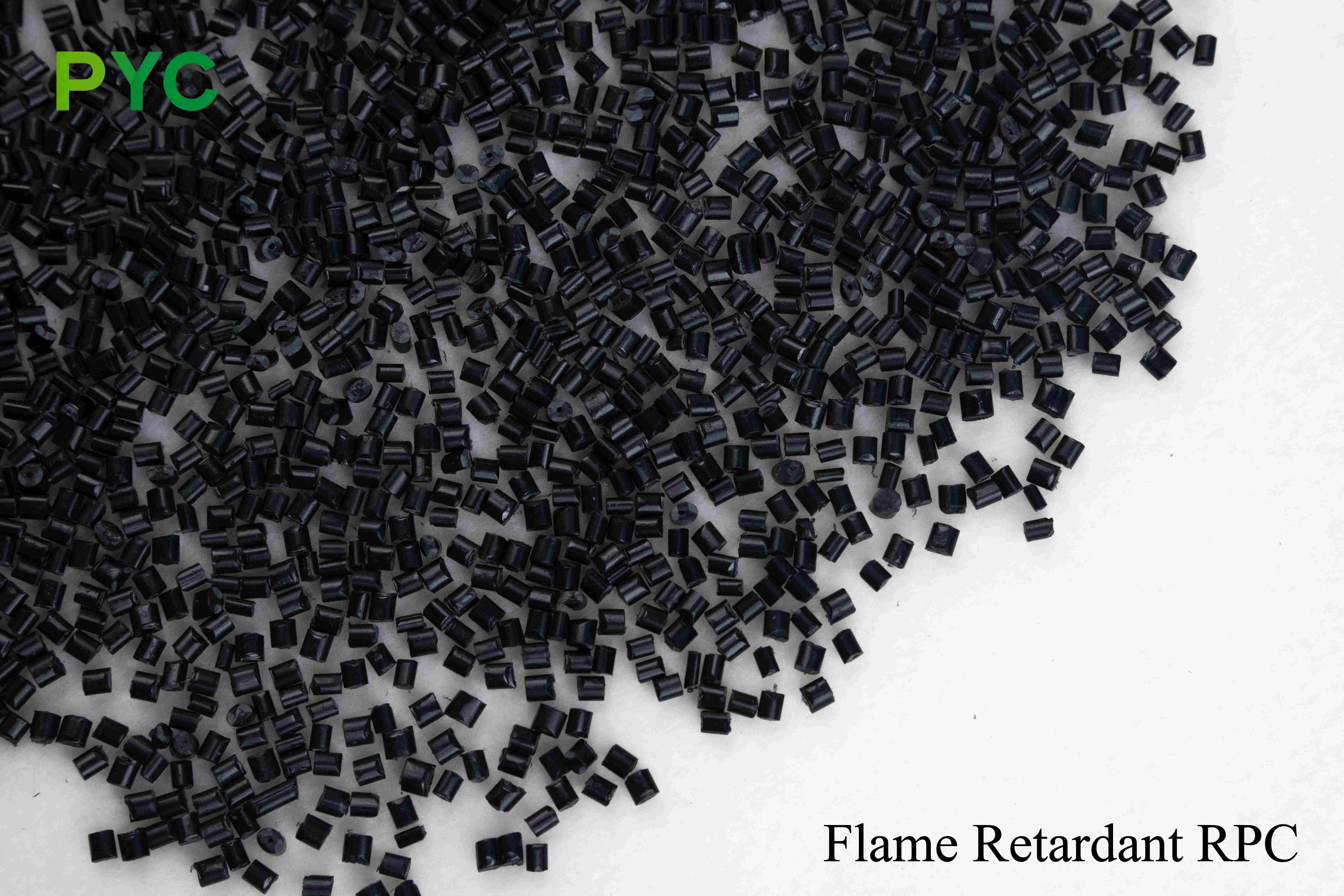

Flame Retardant RPC

High quality recycled raw materials

Flame Retardant RPC uses a single source, carefully screened recycled polycarbonate (PC) as the base feedstock, primarily from high-quality recycled sources such as electronic waste, automotive parts and industrial waste. All raw materials are supplied by highly screened upstream manufacturers to ensure low impurities and high stability, resulting in a final product with excellent flame retardant properties, mechanical strength and thermal stability to meet the requirements of UL 94 V-0 or higher flame retardant applications.

Selected Recycling Sources

Electronic waste: from the power supply housing, server housing, communication equipment housing and other PC components with strict flame-retardant requirements. These materials, originally used in electronic and electrical equipment, have excellent self-extinguishing performance and heat resistance. After recycling, Flame Retardant RPC has excellent fire resistance characteristics and long-term stability.

Automotive components: mainly from automotive electrical system components, fuse boxes, lighting system housings, etc., which have strict requirements for flame retardant and high temperature resistance.

These materials are used in the automotive industry for fire isolation, ensuring that Flame Retardant RPC has excellent burn resistance and mechanical strength for automotive components with high safety requirements.

Industrial waste: includes flame-retardant PC scraps and waste materials generated during industrial production, which are carefully screened, cleaned and modified to ensure low impurity content and consistent flame retardant performance of the product.

Strict quality control

Flame Retardant RPC uses efficient halogen-free flame retardant system or phosphorous/bromine flame retardant technology to maintain excellent mechanical properties and thermal stability while ensuring flame retardant performance, especially suitable for electrical enclosures, building decoration materials, automotive electrical components and equipment with high safety standards.

Each batch of products is subjected to strict flame retardant testing (UL 94, LOI), thermal stability testing and mechanical properties testing to ensure that it still maintains excellent fire resistance and safety under high temperature and high load environment, meeting the needs of different industries for high safety and environmental compliance of flame retardant materials.

Excellent flame retardant performance:

Flame retardant RPC is designed for applications requiring high fire safety with excellent flame retardant performance. The material complies with the international safety standard UL 94 V0 and is able to effectively resist ignition and delay the spread of flame, guaranteeing product safety in high fire risk environments. Even under high temperature and fire conditions, the flame-retardant RPC maintains stable physical properties and minimizes the potential loss caused by fire.

Environmentally friendly recycled materials:

The flame-retardant RPC is made of 100% recycled polypropylene material, which supports the circular economy and reduces the environmental impact of plastic waste. By utilizing renewable resources, the material not only reduces resource consumption and waste emissions, but also helps companies achieve green production and environmental protection goals. It complies with international environmental standards, such as REACH and RoHS, ensuring that it is environmentally friendly during production and use.

Excellent durability:

The material has excellent wear resistance, chemical resistance and resistance to environmental stress cracking. Whether exposed to ultraviolet light, chemicals or extreme weather conditions, the flame retardant RPC is able to maintain its superior physical properties. It is suitable for applications that require long-term use and withstand high intensity work, which can effectively extend the service life of the product and reduce maintenance costs.

Lightweight design:

Compared with traditional flame retardant materials, flame retardant RPC has a lower density and reduces product weight. This not only improves the transportation efficiency, but also reduces the transportation cost. The lightweight feature makes it more competitive in applications that require weight reduction (such as auto parts, electronic product housings, etc.), helping to improve the performance and efficiency of the overall product.

Cost effectiveness:

Flame retardant RPC offers competitive prices with its unique advantages of recycled polypropylene. Due to the use of recycled materials, production costs are effectively controlled, providing enterprises with a more economical solution. Especially in large-scale production, enterprises can not only reduce raw material costs, but also reduce operating costs and enhance market competitiveness.

Flame retardant RPC (recycled polypropylene copolymer) is a new type of high performance material, designed to meet the dual needs of fire protection and durability in modern industry. Made from 100% recycled polypropylene material, it combines environmental protection and high performance features, providing the ideal solution for a wide range of applications in electrical equipment, automotive, building materials and other industries.

The biggest feature of the material is its excellent flame retardancy, which can effectively resist the ignition of the fire source and slow the spread of the flame, ensuring the maximum protection of personal and property safety in the environment with high fire risk. Flame retardant RPC by adding efficient flame retardants, to meet the international standard UL 94 V0 performance requirements, to provide users with a high level of fire safety protection. Whether it is in the shell of electrical equipment, automotive parts, or building materials, the application of flame retardant RPC can significantly improve the overall fire protection capability and reduce the loss caused by fire.

Flame-retardant RPC has also won the market favor for its environmental protection characteristics. It is made entirely of recycled polypropylene, making full use of waste plastic materials, reducing resource waste and reducing carbon emissions, in line with the global green trend. Compared with traditional plastic materials, the production process of flame retardant RPC is more energy saving and environmental protection, helping enterprises to fulfill social responsibilities and promote sustainable development while meeting market demand.

In addition to excellent flame retardant and environmental protection properties, flame retardant RPC also has extremely high durability. It has strong resistance to chemical corrosion and environmental stress cracking, and can withstand the test of harsh environments such as ultraviolet light, acid and alkali and high temperature. Therefore, in the long time of use and harsh working conditions, flame retardant RPC still maintains stable physical properties, greatly extending the service life of the product, reducing maintenance and replacement costs.

In addition, flame retardant RPC also has a lower density, suitable for lightweight product applications. Its lightweight features make transportation more efficient, while also helping to reduce transportation costs. In the fields of auto parts, electronic equipment shells, etc., the application of flame-retardant RPC not only improves the safety and performance of the overall product, but also reduces the weight of the product, further enhancing the competitiveness.