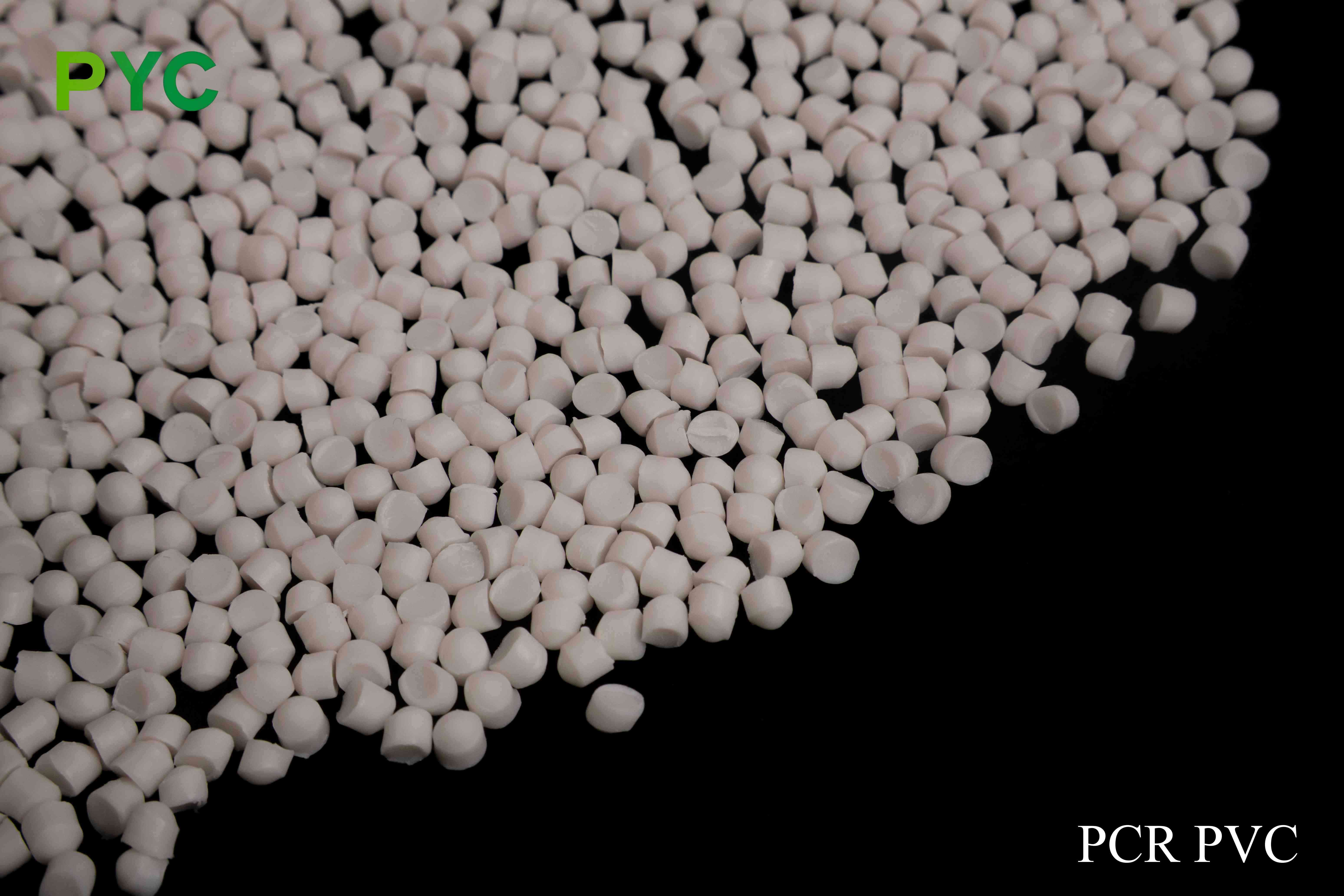

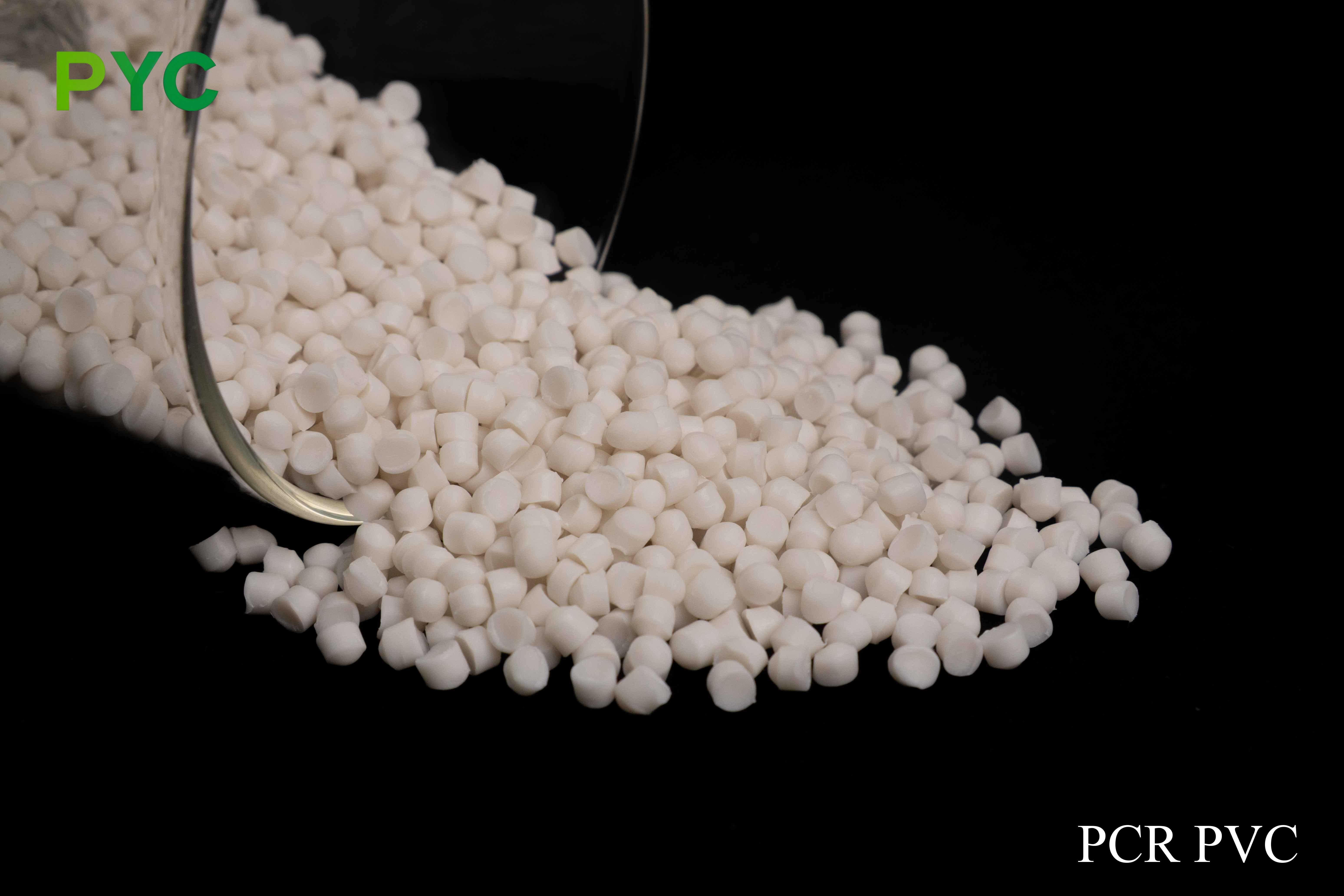

PCR PVC

PCR PVC (Post Consumer Recycled Polyvinyl Chloride) is an innovative, environmentally friendly plastic made from recycled polyvinyl chloride material used in a wide range of industries, including construction, packaging, electronics and automotive. Its excellent performance and environmental protection properties have made it increasingly recognized and applied in the market.

Product Details:

High quality recycled raw materials

The raw material for PCR PVC is primarily derived from recycled polyvinyl chloride (PVC) waste that has been screened and treated, often from products after use by consumers.

Specific sources include

Discarded building materials: PVC is widely used in the construction industry, especially in building products such as pipes, window frames, flooring materials, etc.

Scrap cable insulation: The power and communication industries use a lot of PVC cables, especially as external insulation for cables. Used waste cables are recycled and treated and converted into PCR PVC raw materials.

Waste packaging materials: PVC is widely used in the packaging industry, including food packaging, pharmaceutical packaging, toy packaging and so on. After consumer use, these packaging materials are collected and processed through recycling channels to be regenerated into PCR PVC.

Waste mulch and agricultural film: In the agricultural industry, PVC material is used as mulch film, greenhouse film, etc. As the end of its useful life, the waste agricultural film is collected for recycling.

Consumer waste: such as PVC seats, plastic household items, toys and other daily consumer goods after the use of waste.

Strict quality control: In the production process, PCR PVC will undergo a series of tests such as melt index (MFI), tensile strength, impact toughness and chemical resistance to ensure the stability and durability of the material. Its excellent rigidity, impact resistance and weather resistance make it widely used in building materials, electronic shell, auto parts and other fields.

Environmental protection and sustainability: As a recycled material, PCR PVC helps reduce plastic waste and meets global requirements for environmental protection and sustainable development. The use of PCR PVC can reduce the need for new raw materials, reduce carbon dioxide emissions and promote the development of a green economy.

Excellent mechanical properties: PCR PVC has good rigidity and strength and is suitable for applications that require high strength and durability. In addition, its excellent chemical resistance enables it to be used for a long time in harsh environments, protecting internal items from corrosion.

Wide range of applications

PCR PVC is widely used in a number of industries, especially in the construction industry, where it is favored as a pipe, window frame and flooring material due to its durability and ease of processing. In the packaging sector, PCR PVC is used to make transparent and flexible packaging materials, ensuring product visibility and safety.

Field of application

PCR PVC performs well in several fields such as construction, packaging, electronics and automotive. In the construction industry, PCR PVC is mainly used to make pipes, window frames, and flooring materials with excellent durability and corrosion resistance. In the electronics industry, as a shell material, PCR PVC can effectively protect internal components. In the field of packaging, PCR PVC is widely used in transparent packaging of food and non-food, ensuring the safety and visibility of products.

Product performance and advantages

PCR PVC material has excellent physical and chemical properties, can withstand high temperature, low temperature and chemical corrosion. Its excellent impact resistance and rigidity make it suitable for manufacturing a variety of durable products. In addition, the production process of PCR PVC follows environmental protection standards, reducing the need for new raw materials and in line with the concept of sustainable development.

Production and technical advantages

The production process of PCR PVC uses advanced recycling technology to ensure the high quality of the material and low impurity content. Through the optimized processing process, PCR PVC can easily adapt to a variety of processing methods such as injection molding, extrusion and blow molding to meet the needs of different products.

Environmentally friendly and cost effective

As a recycled material, PCR PVC reduces the environmental burden and helps reduce plastic waste. At the same time, the use of PCR PVC as a raw material can effectively reduce production costs and improve the competitiveness of enterprises. The wide application of PCR PVC not only promotes the popularity of environmental protection concepts, but also provides enterprises with economic solutions for sustainable development.

In general, PCR PVC is gradually becoming a popular recycled material in the market with its excellent performance, environmental protection advantages and a wide range of application scenarios. It not only provides high-performance plastic products, but also lays a solid foundation for enterprises to achieve green production and sustainable development goals.