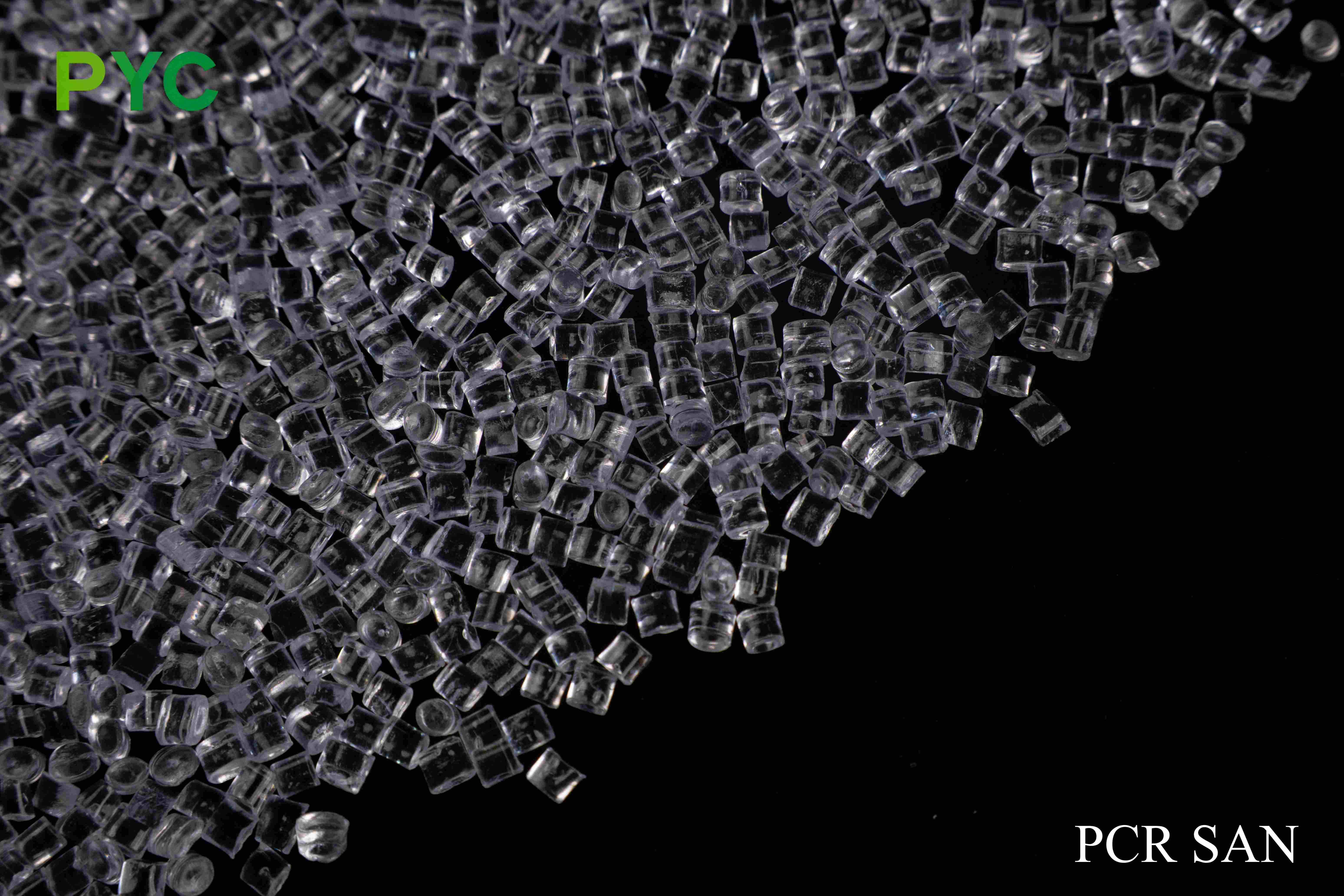

PCR SAN

Our PCR EVA is made from high-quality recycled materials, providing a sustainable alternative for various applications. By utilizing post-consumer recycled content, this material reduces the reliance on virgin plastics, contributing to the circular economy while maintaining the high-performance characteristics of traditional EVA.

Recycling process

The recycling process for a high-quality PCR SAN usually involves the following steps:

Collection and classification: Collect discarded SAN products and classify them according to material and contamination level.

Cleaning and pretreatment: The recovered SAN materials are cleaned to remove impurities and contaminants, and decolorized if necessary.

Pulverization and melting: The cleaned SAN material is pulverized and then processed into recycled particles by the melting process.

Precision filtration: Advanced filtration technology is used to remove small impurities in the molten SAN and ensure the purity of the recycled material.

Quality testing: Quality testing of recycled particles to ensure that their performance meets relevant standards and application requirements.

Product Details Performance and advantages:

High transparency and gloss: suitable for applications requiring good visual effects, such as transparent packaging, display screens, display cases, etc.

Good chemical resistance: with strong acid and alkali resistance, can resist the corrosion of common chemicals, very suitable for use in the industry that requires chemical stability.

Strength and rigidity: PCR SAN has high rigidity and good impact resistance, which can effectively work in the environment where hard materials are required.

Easy to process: Due to its good fluidity, PCR SAN is easy to process by injection molding, extrusion and other processes, suitable for a variety of different molding methods.

Production and technical advantages:

Advanced recycling process: Through innovative recycling technology, PCR SAN is close to the performance of the original styrene acrylonitrile copolymer, while improving the stability of the material.

Excellent processing adaptability: PCR SAN can be molded through a variety of processing methods, including injection molding, blow molding, extrusion, etc., to adapt to different forms and needs of production.

Environmental protection and sustainability:

Reduce resource consumption: The use of recycled materials not only reduces the dependence on new resources, but also effectively reduces the accumulation of plastic waste, in line with environmental protection requirements.

Promoting circular economy: PCR SAN promotes the recycling of plastic materials, in line with green production and sustainable development goals, and helps companies achieve environmental protection goals.