RPC

High quality recycled raw materials

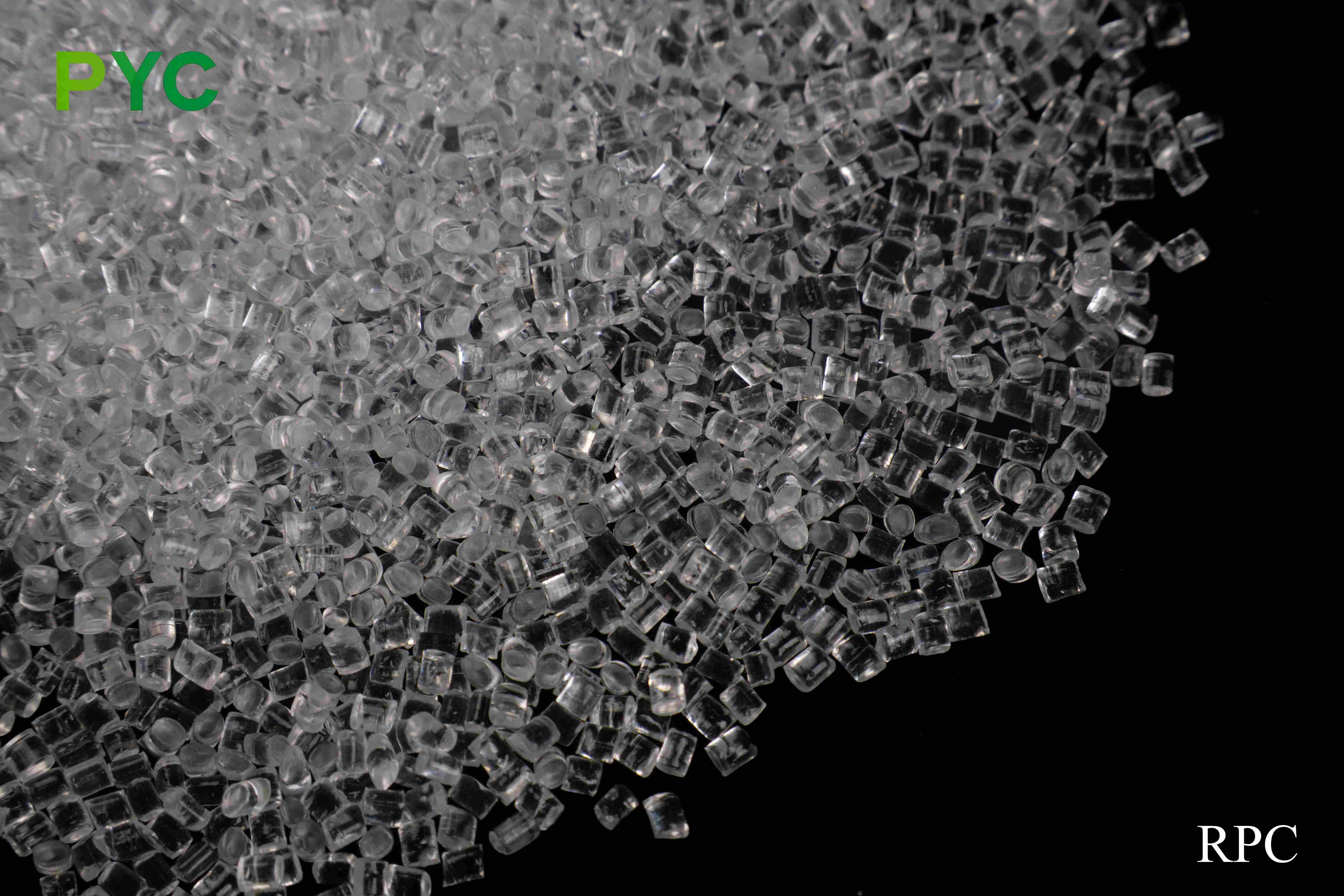

RPC (Recycled Plastic Composite) uses high-quality recycled plastics as the basic raw materials, combined with advanced composite technology, to produce composite materials with excellent properties. By using recycled plastics from a single source and carefully screened to ensure their low impurities and high stability, the final product has excellent mechanical properties, durability and environmental protection characteristics.

Select Recycling Sources

E-waste: Derived from discarded electronic products such as smartphone cases, computer accessories, TV casings, etc. The electronic waste is carefully screened and cleaned to ensure the high quality, low impurities and good physical properties of the recycled plastic, which is suitable for the production of high-performance RPC materials.

Auto parts: from the plastic parts used in the car, such as lamp shell, instrument panel, interior decoration, etc.

After recycling, these materials have high stability and impact resistance, ensuring the reliability and durability of RPC materials in various application scenarios.

Industrial waste: including plastic waste and scraps generated in the industrial production process, after fine screening, cleaning and treatment to ensure low impurities and stable physical properties. Suitable for the manufacture of high strength requirements, long-term use of the environment can still maintain stable performance of composite materials.

Product Advantages

High toughness and mechanical properties: By optimizing the composition of the composite material, RPC material has excellent tensile strength, impact resistance and durability, which is suitable for a variety of high-load, long-term use applications.

Environmental protection and sustainable: The use of recycled plastics as raw materials reduces resource waste, and helps to reduce environmental pollution, in line with modern environmental protection requirements.

Widely used: RPC material can be used in automotive parts, electronic products shell, building materials, home appliances and other fields, showing its excellent mechanical and physical properties in various industries.

Strict quality control

RPC materials undergo strict quality testing in the production process to ensure that each batch of products meet industry standards in terms of mechanical properties, durability, environmental protection standards, etc. Products comply with RoHS, REACH and other international environmental protection certification, to ensure the minimum impact on the environment during use.

Each batch of products has been comprehensively tested to ensure the excellent performance and stability of RPC materials, to meet the needs of different industries for environmentally friendly, safe and durable materials.

Excellent mechanical properties and durability

RPC has excellent mechanical strength and impact resistance, and can withstand large external forces, and is widely used in applications requiring high strength and impact resistant materials. The material maintains the characteristics of the original polycarbonate, and can still maintain stable physical properties in high temperature and low temperature environment.

Environmental Protection and sustainability

RPC is made from recycled polycarbonate material, in line with sustainable development goals. The use of RPC not only helps to reduce the environmental burden of plastic waste, but also meets environmental standards such as REACH and RoHS to meet global environmental requirements.

A wide range of applications

RPC can be widely used in electronic equipment enclosures, automotive parts, building materials, optical materials and other fields, especially for products requiring high transparency and impact resistance. Through recycling and processing, RPC has huge market potential in electronics, electrical, construction and other industries.

RPC is made by recycling old polycarbonate materials (such as discarded electronic device housings, CD cases, LED luminaires housings, etc.) for processing. Through rigorous screening and efficient cleaning treatment, recycled polycarbonate can maintain its excellent mechanical properties and chemical stability, which can meet the needs of different applications.

Excellent Mechanical properties

RPC has high strength, good impact resistance and pressure resistance, and can maintain good physical properties in extreme environments. Whether it's an electronic case, an automotive component, or a durable material for the construction industry, RPC can provide reliable support for the product.

Transparency and Optical properties

Like traditional polycarbonate materials, RPC maintains advantages in transparency and optical properties, and is suitable for applications that require high transparency, such as optical lenses, display screens, etc.

High and low temperature resistance

RPC can maintain stable performance in both high and low temperature environments, and is particularly suitable for applications in the automotive, electronics and construction industries, and can adapt to a wide range of temperature changes.

Processing adaptability

RPC can be applied to a variety of processing processes, including injection molding, extrusion, blow molding, etc., and is compatible with existing production equipment, helping enterprises to reduce production costs and improve manufacturing efficiency.

Environmental Protection and Sustainable development

RPC is produced by recycling raw materials and complies with environmental certifications such as REACH and RoHS, which can effectively reduce resource waste and carbon emissions and help enterprises achieve sustainable development goals. Its recycling nature provides companies with more environmentally friendly plastic solutions.