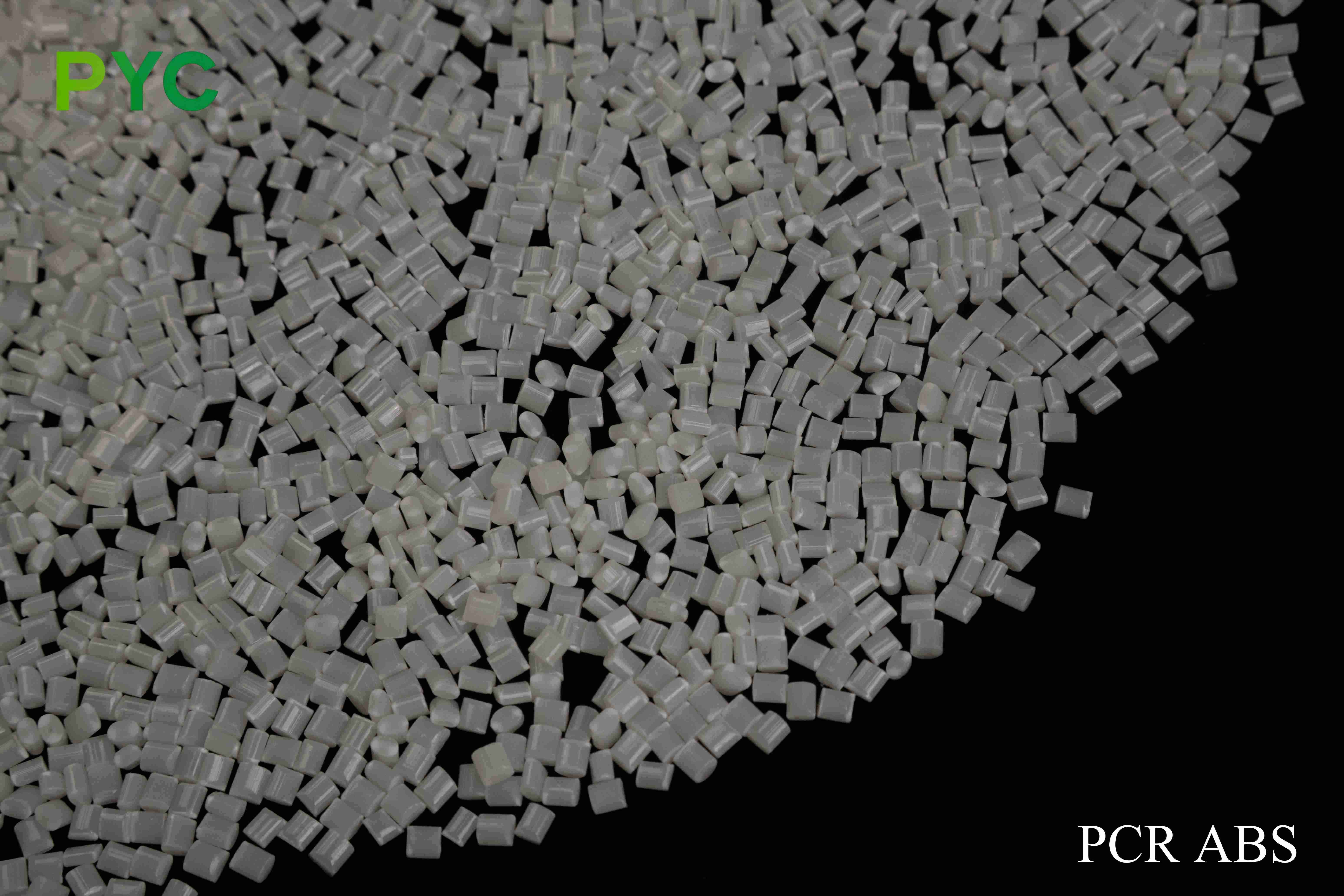

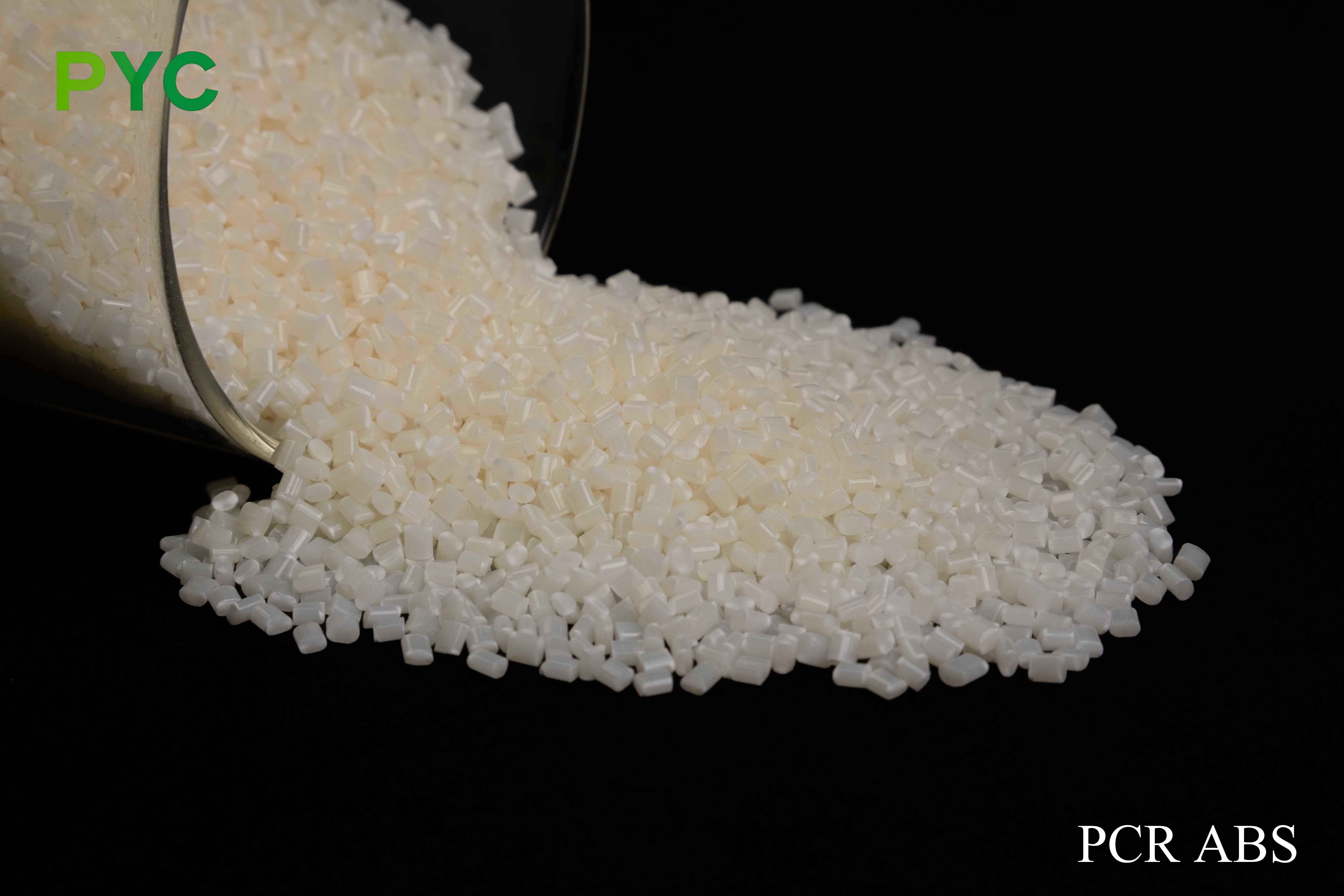

PCR ABS

Polymerase Chain Reaction (PCR) ABS (Post Consumer Recycled acrylonitrile butadiene styrene copolymer) is an environmentally friendly plastic produced by recycling post-consumer waste ABS materials and then reprocessing them. As a widely used engineering plastic, ABS has excellent toughness, impact resistance and good surface gloss. Through recycling and reprocessing, PCR ABS not only retains these excellent characteristics, but also effectively reduces the dependence on raw materials, which is in line with the current environmental protection trend of sustainable development.

Product Details

High quality recycled raw materials

Used electronic casing

ABS materials are widely used in electronic product housings, such as the housings of computers, televisions, mobile phones and household appliances. With the obsolescence and replacement of electronic products, discarded electronic casings have become an important source of PCR ABS. Due to the widespread and large number of ABS materials used in electronic equipment, these used electronic casings can provide a large amount of recycled raw materials.

Examples of recycling sources:

Home appliance shell: For example, the shell of household appliances such as TV sets, refrigerators, air conditioners, microwave ovens may be made of ABS material.

Computer housings: Discarded computer housings, monitor housings, external accessories such as keyboards and mice.

Mobile phone cases: cases for smartphones, feature phones, etc., especially the rear cover and bezel parts.

Audio equipment housing: Audio systems, Bluetooth speakers, home theater equipment housing is usually also made of ABS material.

Interior and exterior parts of the car

ABS is one of the commonly used engineering plastics in the automotive industry, especially in the automotive interior, exterior and structural parts. With the end of the life cycle of automobiles, discarded auto parts become one of the sources of PCR ABS. After being disassembled, these parts can be recycled and converted into new PCR ABS raw materials for the manufacture of new auto parts or other products.

Examples of recycled sources:

Automotive interior parts: such as dashboards, door linings, plastic parts of seats, air conditioning panels, etc.

Automobile exterior decoration: such as lamp shell, logo, front and rear bumper, grille, window frame, etc.

Automobile structural parts: such as the plastic plate at the bottom of the car, the edge decoration of the body, etc.

Center console: the center control panel, sound control button, console and so on are usually made of ABS material.

Toy products

ABS material is widely used in the manufacture of children's toys because of its good processability and high impact resistance. With the obsolescence or elimination of toys, discarded toys become one of the sources of PCR ABS. Especially some large plastic toys, such as remote control cars, building block toys, puzzle toys, etc., they often use ABS as the main raw material.

Examples of recycling sources:

Building block toys: ABS materials are often used for Lego blocks, interleaved toys, etc.

Remote control car, robot: remote control vehicle in various plastic toys, robot toy shell, etc.

Educational toys: such as plastic puzzles, model toys, etc., are also usually made of ABS materials.

Industrial waste and production scraps

In the production process of ABS, there are often some wastes or scraps, which still maintain high raw material quality during the processing process. Therefore, these industrial wastes and scraps also become the recycling source of PCR ABS, which can be converted into high-quality PCR ABS raw materials for manufacturing new products after recycling and reprocessing.

Examples of recycled sources:

Injection castoffs: In injection molding production, some scraps and wastes can be recycled and converted into high-quality PCR ABS raw materials.

Extruded castoffs: The waste produced in the extrusion process is recycled and can be used as raw material for PCR ABS.

Mold waste: During the production process, due to adjustments or errors in mold design, the resulting waste can be recycled and converted into new PCR ABS raw materials.

Scrap consumer and industrial products

Some plastic consumer and industrial products become a source of raw materials for recycling at the end of their useful lives. These include discarded storage boxes, office furniture, sanitation, etc. In particular, for bulk plastic products, their recycling helps to provide a large amount of PCR ABS raw material.

Examples of recycling sources:

Plastic containers and storage boxes: such as discarded plastic storage boxes, office stationery, household plastic products, etc.

Office furniture: such as plastic chairs, desktop decorative boards, file holders, etc.

Trash cans and waste collection containers: Some discarded trash cans, plastic pallets, etc., also often use ABS materials.

Recycling process

Recycled PCR ABS materials usually need to go through the following processing steps:

Preliminary screening and sorting: Discarded ABS material is initially screened manually or mechanically to remove other plastics, metals and impurities.

Cleaning: Remove contaminants, oil, labels and adhesives, etc., to ensure the purity of raw materials.

Crushing and granulation: The discarded ABS material is broken and granulated to facilitate subsequent processing and reuse.

Quality testing: After quality control, the strength, transparency, toughness and other performance indicators of PCR ABS materials are tested to ensure that they meet industry standards.

Reprocessing into new products: The final PCR ABS is used in injection molding, extrusion and other processes to manufacture new products.

Fields of Application:

Automotive industry

PCR ABS is widely used in automotive interior parts, instrument panels, car lampshades and other parts. Its impact resistance and thermal stability ensure that auto parts can work stably in both high and low temperature environments, improving the safety and comfort of the vehicle.

Electronics

In the consumer electronics sector, PCR ABS is widely used in the production of housings and components such as mobile phones, televisions, computers and home appliances. Its good surface gloss and impact resistance make electronic products more durable during use and more beautiful in appearance.

Home appliance industry

PCR ABS is commonly used in the production of home appliance components such as home appliance housings, kitchen appliances, washing machines and refrigerators. Its excellent impact resistance makes home appliances more resistant to breakage in daily use.

Construction and Decoration

PCR ABS is also suitable for the production of building decoration materials, interior furniture accessories, etc. Its high surface gloss and wear resistance make it excellent in decorative applications.

Performance advantages and technical features:

Enhanced impact strength and wear resistance compared with traditional materials, PCR ABS has higher impact resistance and can withstand high strength impact load without breaking easily. It is especially suitable for the requirements of automotive, electronic products and home appliances.

Thermal stability and high temperature resistance

PCR ABS can still maintain good performance in the temperature range of 40°C to +85°C, suitable for high temperature working environments, ensuring product stability under extreme conditions.

Excellent processability PCR ABS can be processed by injection molding, extrusion and other ways, and can accurately shape complex parts to meet the fine requirements of different industries for materials.

Environmental protection and cost effectiveness:

Recycling and environmental reduction

Through the use of PCR ABS, enterprises can effectively reduce the dependence on new raw materials, reduce the consumption of oil resources, while reducing the accumulation of plastic waste, reduce carbon emissions.

Due to the use of recycled materials, the production cost of PCR ABS is lower than that of ABS using entirely new raw materials, helping companies to reduce production costs while meeting the global market demand for sustainable products.