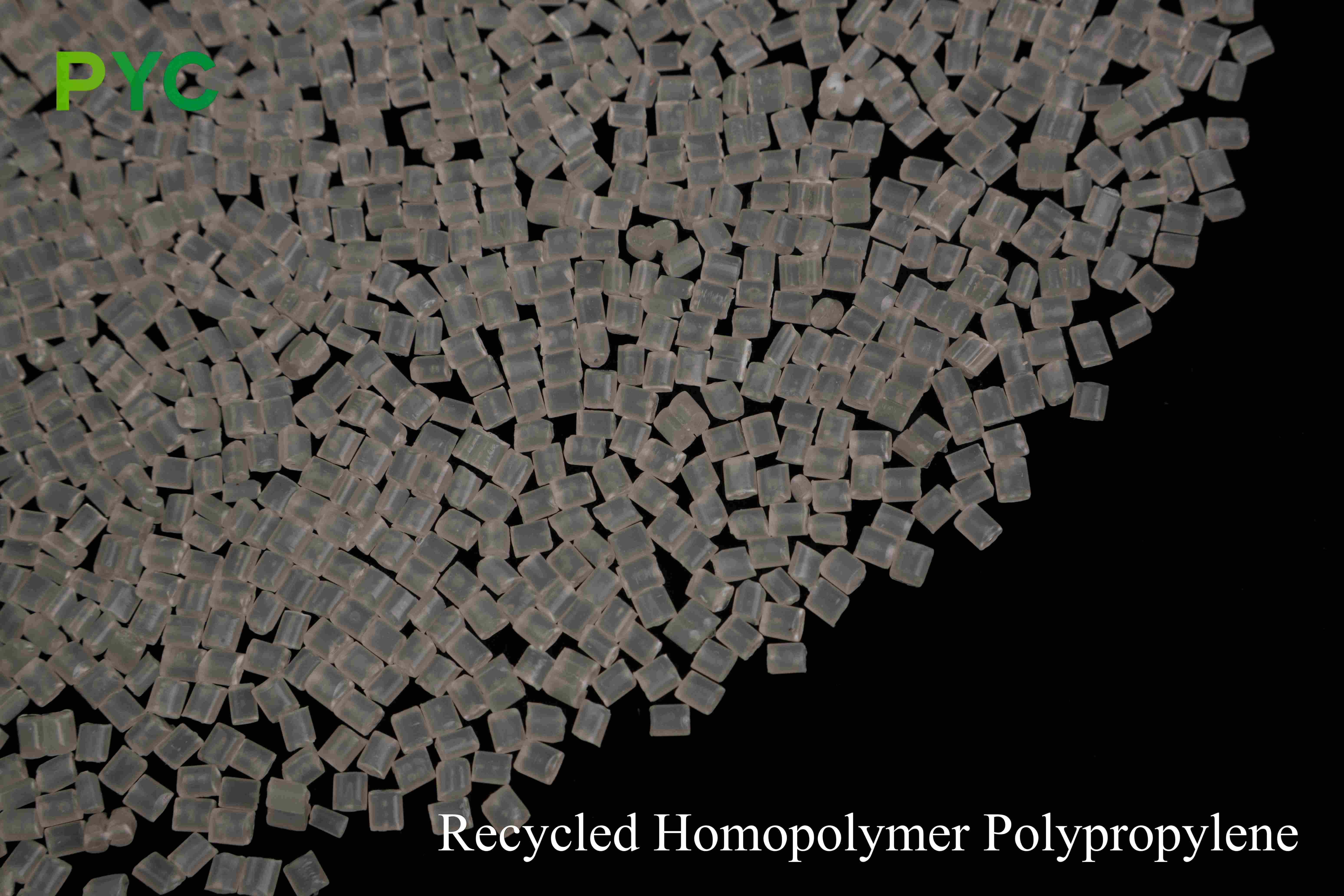

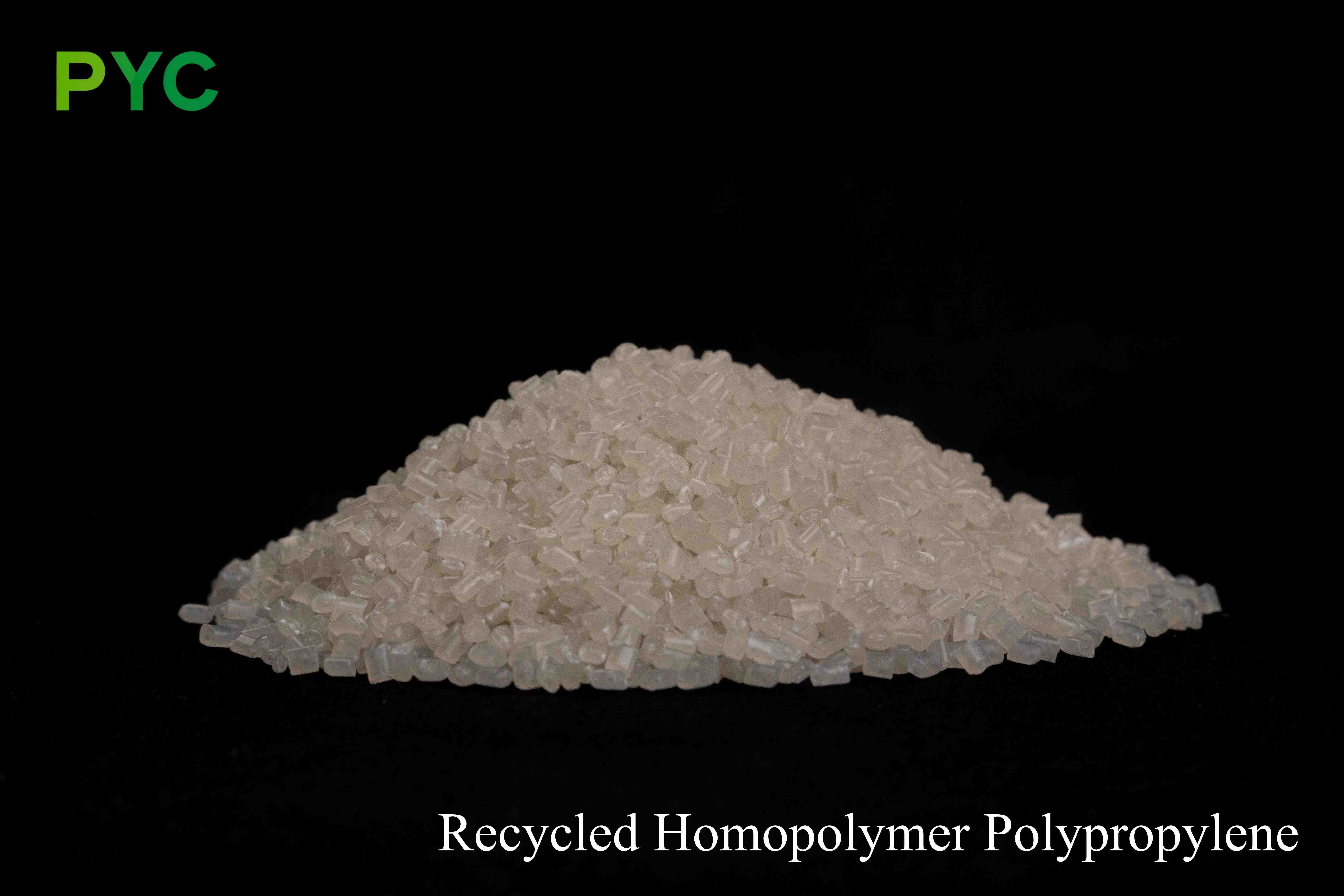

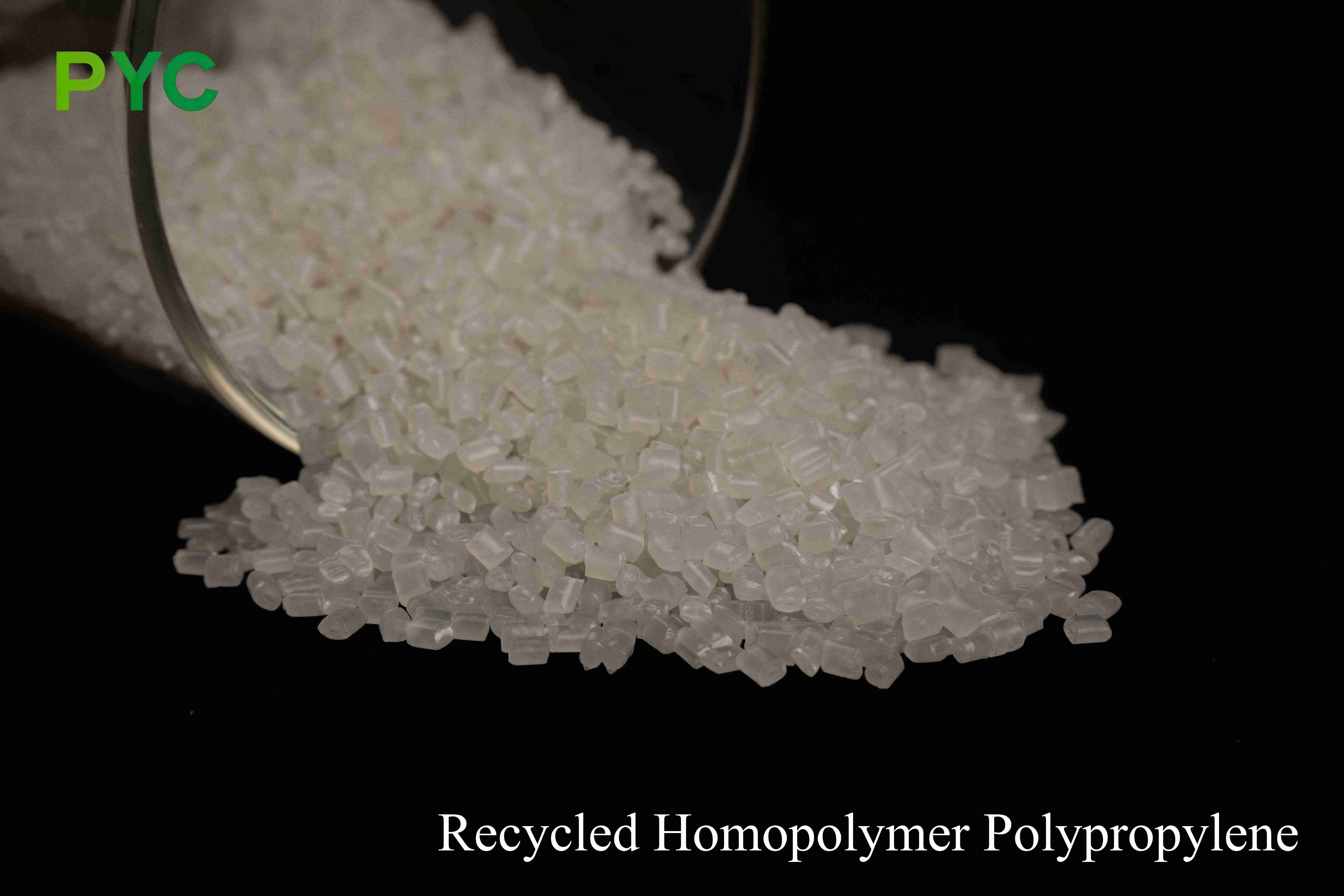

Recycled Homopolymer Polypropylene

Recycled Homopolymer Polypropylene is a durable and cost-effective material with high stiffness and good processability. It is ideal for applications such as packaging, household products, and industrial components. Available in injection molding and extrusion grades.

products details

High quality recycled materials

Source of raw materials and their specific descriptions:

Plastic packaging materials

Homopolymer polypropylene is widely used to make a variety of packaging materials, such as food packaging, pharmaceutical packaging, etc. These discarded packaging materials are an important source of recycled homopolyPP.

Examples of recycled sources:

Food packaging containers: disposable food packaging containers can be recycled after use.

Drug packaging bottles: The drug packaging bottles after use are also a channel for homopolylene-polypropylene recycling.

Plastic bottle caps

Many beverage bottle caps are made of homopolymer polypropylene. These discarded caps are recycled and can be used as a raw material source for high-quality recycled homopolymer polypropylene.

Examples of recycled sources:

Drink bottle caps: Drink bottle caps can be recycled after use.

Plastic tubing

Homopolymer polypropylene is widely used in pipe manufacturing, especially in areas such as hot and cold water pipes. The discarded or replaced pipes can be used as raw materials for recycled homopolyPP.

Examples of recycled sources:

Water pipe: Waste polypropylene water pipe can be recycled.

Plastic furniture

Many plastic furniture, such as chairs, tables, etc., are made of homopolymer polypropylene. This discarded furniture is recycled and can be used to produce high quality recycled homopolyPP.

Examples of recycled sources:

Plastic chairs: Discarded plastic chairs can be used as raw materials for homopolymer polypropylene recycling.

Industrial waste

In the production process of plastic products, some scraps or defective products will be produced, and these industrial wastes are also an important source of recycled homopolymer polypropylene.

Examples of recycled sources:

Production scraps: Scraps produced in the production process of plastic products can be recycled.

Recycling process

The recycling process for recycled homopolymer polypropylene usually involves the following steps:

Collection and sorting: The discarded homopolyPP products are collected and sorted according to the material and level of contamination.

Cleaning and disinfection: The recycled plastics are cleaned to remove impurities and contaminants, and sterilized if necessary.

Crushing and granulation: The cleaned plastic is crushed and then processed into pellets by a granulator.

Quality inspection: The quality inspection of the recycled particles is carried out to ensure that it meets the relevant standards and application requirements.

Strict quality control

In the production process, all recycled homopolymer polypropylene is subjected to strict quality control to ensure that every batch of products meet international standards. We carry out a series of tests on our products, including tensile strength, impact resistance, melt index, etc., to ensure that the final product has stable performance and consistent quality. Through meticulous quality control, we ensure that each product can provide reliable performance in different applications.

Excellent mechanical properties

High strength and rigidity: recycled homopolymer polypropylene has high tensile strength and rigidity, which is suitable for applications requiring structural strength and stability.

Good impact resistance: although its impact resistance is not as good as copolymer polypropylene, it still has good impact resistance and is suitable for the durability needs of daily applications.

Low density: Due to its homopolymer structure, rPP homopolymer maintains a low density, which allows it to maintain strength while still providing a light weight, suitable for products requiring lightweight materials.

Be cost effective

One of the biggest advantages of recycled homopolymer polypropylene is its significant cost effectiveness. By using recycled materials, rPP homopolymer helps reduce production costs without sacrificing the performance of the product. rPP homopolymer offers a competitive price advantage over brand new raw materials, making it particularly suitable for cost-sensitive industries.

5. Environmental protection and sustainability rPP homopolymer's recycling process significantly reduces plastic waste, reduces reliance on new resources and drives the green economy. The use of recycled materials helps to lower energy consumption, reduce greenhouse gas emissions and provide companies with solutions that are in line with global environmental and sustainable development goals.

Packaging industry:

Rigid packaging containers: recycled homopolymer polypropylene is widely used in food, home appliances, daily consumer goods of rigid packaging containers, such as plastic bottles, containers, LIDS, etc., because of its high strength and rigidity, can provide strong shell protection.

Flexible packaging materials: rPP homopolymer can also be used in the production of packaging materials such as packaged food, shopping bags, etc., with good tensile and durability.

Automotive Industry:

Automotive interior parts: Used to manufacture automotive interior parts, such as door panels, instrument panels, compartment accessories, etc., with good strength, durability and impact resistance, to meet the high requirements of the automotive industry.

External body parts: such as bumpers, exterior trim, etc., provide good mechanical properties and long-term weather resistance.

Household items and consumer goods:

Plastic storage bins, furniture accessories, household plastic products: Due to its excellent rigidity and strength, rPP homopolymer can be widely used in the production of durable products such as household items, kitchen accessories, tables and chairs.

Toys and home decorations: rPP homopolymer is often used in the production of children's toys and home decorations due to its non-toxicity and good processing adaptability.

For the construction industry:

Building materials: rPP homopolymer also has applications in the construction industry, such as plastic pipes, insulation materials, etc., to provide stable physical properties and meet the needs of the construction industry.

Product performance and advantages:

High strength and rigidity: Recycled homopolymer polypropylene retains the essential advantages of polypropylene, including high strength, rigidity and good impact resistance, making it ideal for applications that require high loads or shape retention.

Uv resistance and weather resistance: rPP homopolymer is well weather-resistant and can

be used for long periods of time in outdoor exposure without aging or deterioration in performance.

Low cost: The use of recycled polypropylene as a raw material, lower production costs, especially suitable for cost-sensitive markets, to help companies reduce production costs.

Production and technical advantages:

Efficient recycling process: Through advanced recycling technology and optimized processing technology, the production process of rPP homopolymer not only reduces energy consumption, but also improves the quality and performance stability of materials.

A variety of processing methods: rPP homopolymer has good processing adaptability and can be processed by injection molding, extrusion, blow molding and other processes to meet different product shapes and needs.

Environmental protection and sustainability:

Promoting green production: By using recycled polypropylene raw materials, rPP homopolymer is able to effectively reduce the environmental burden of waste and contribute to sustainable production.

Reducing carbon emissions: Compared to the production of new polypropylene, the production process using recycled materials can significantly reduce carbon emissions, and is an important step in achieving the company's green production and environmental protection goals.