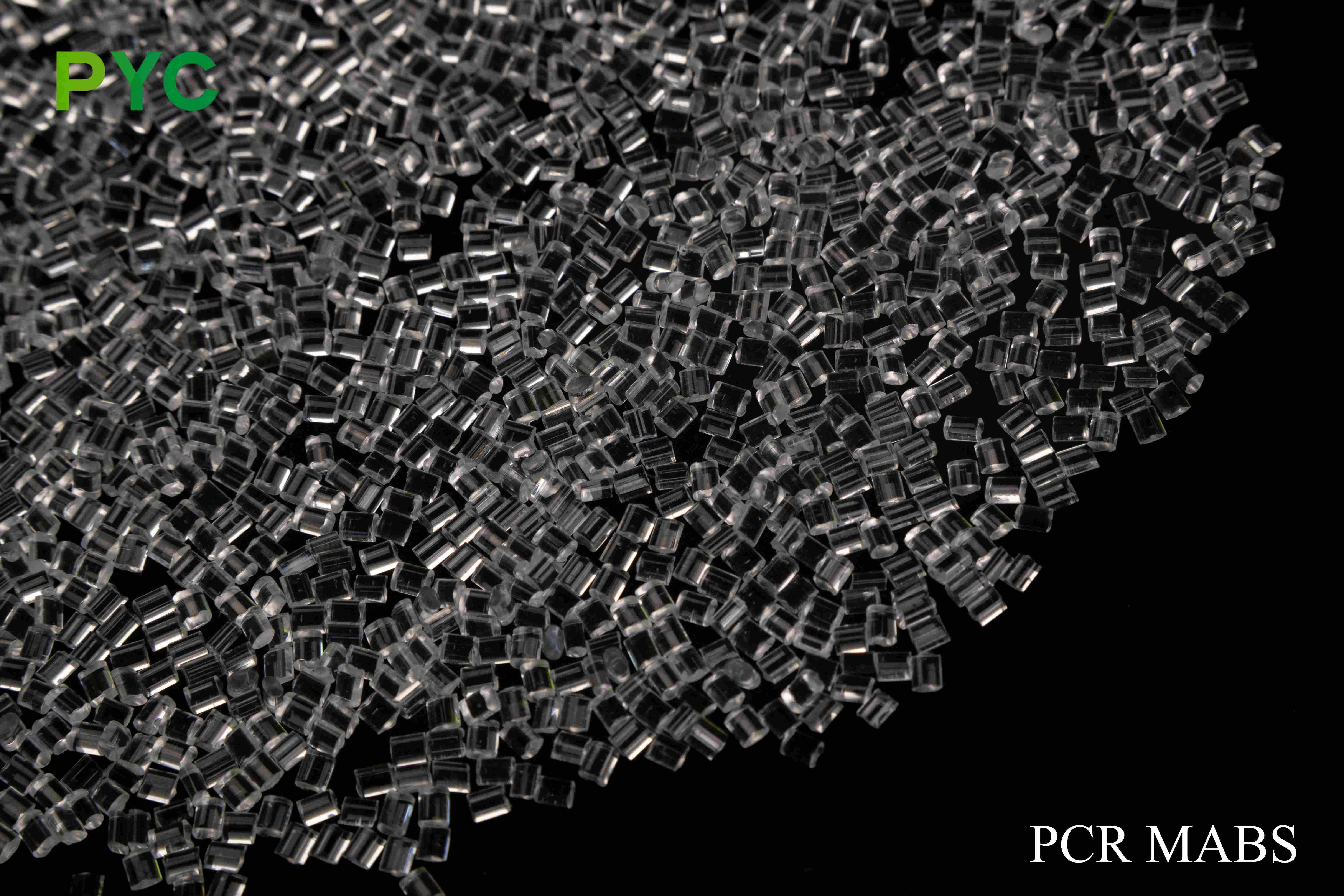

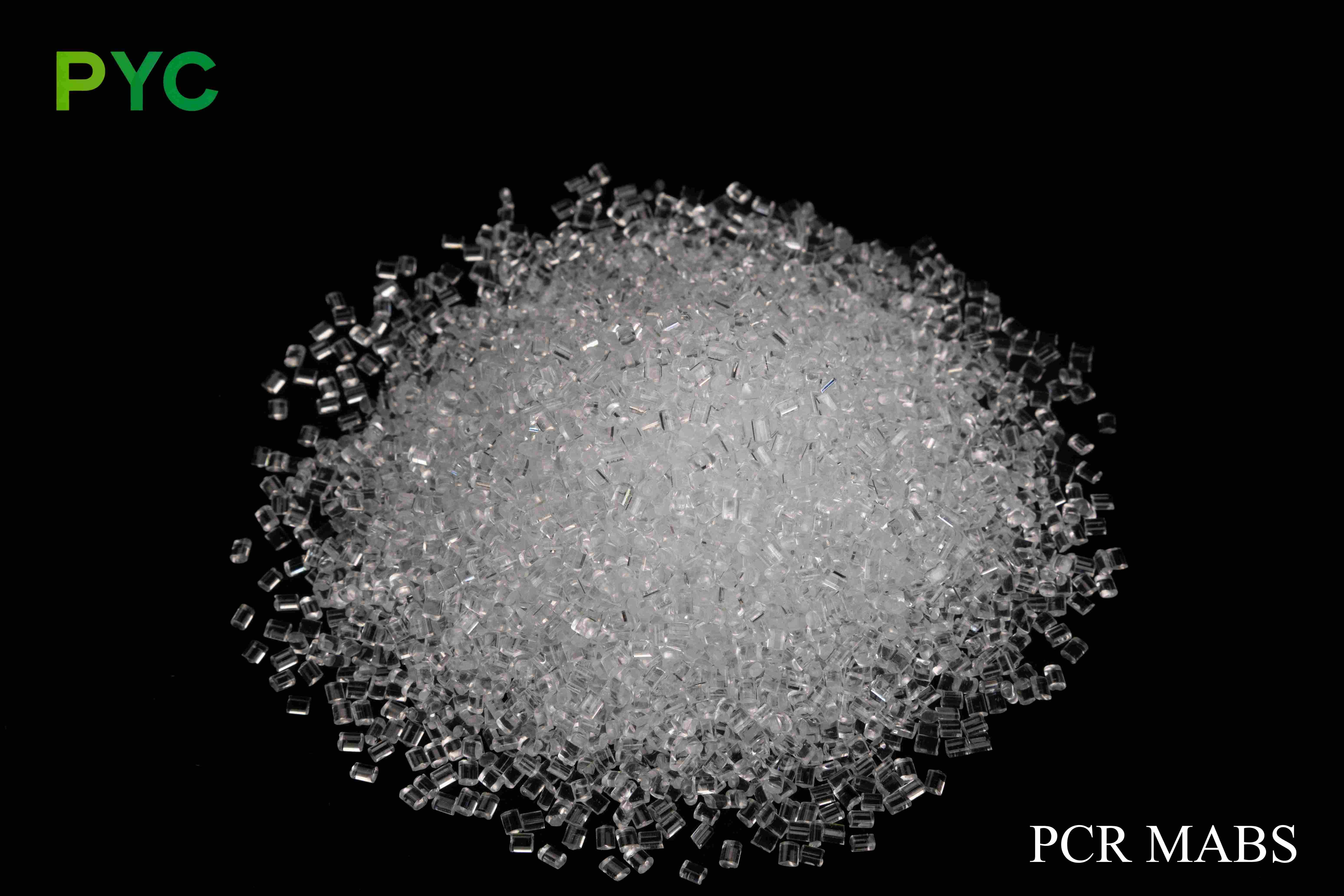

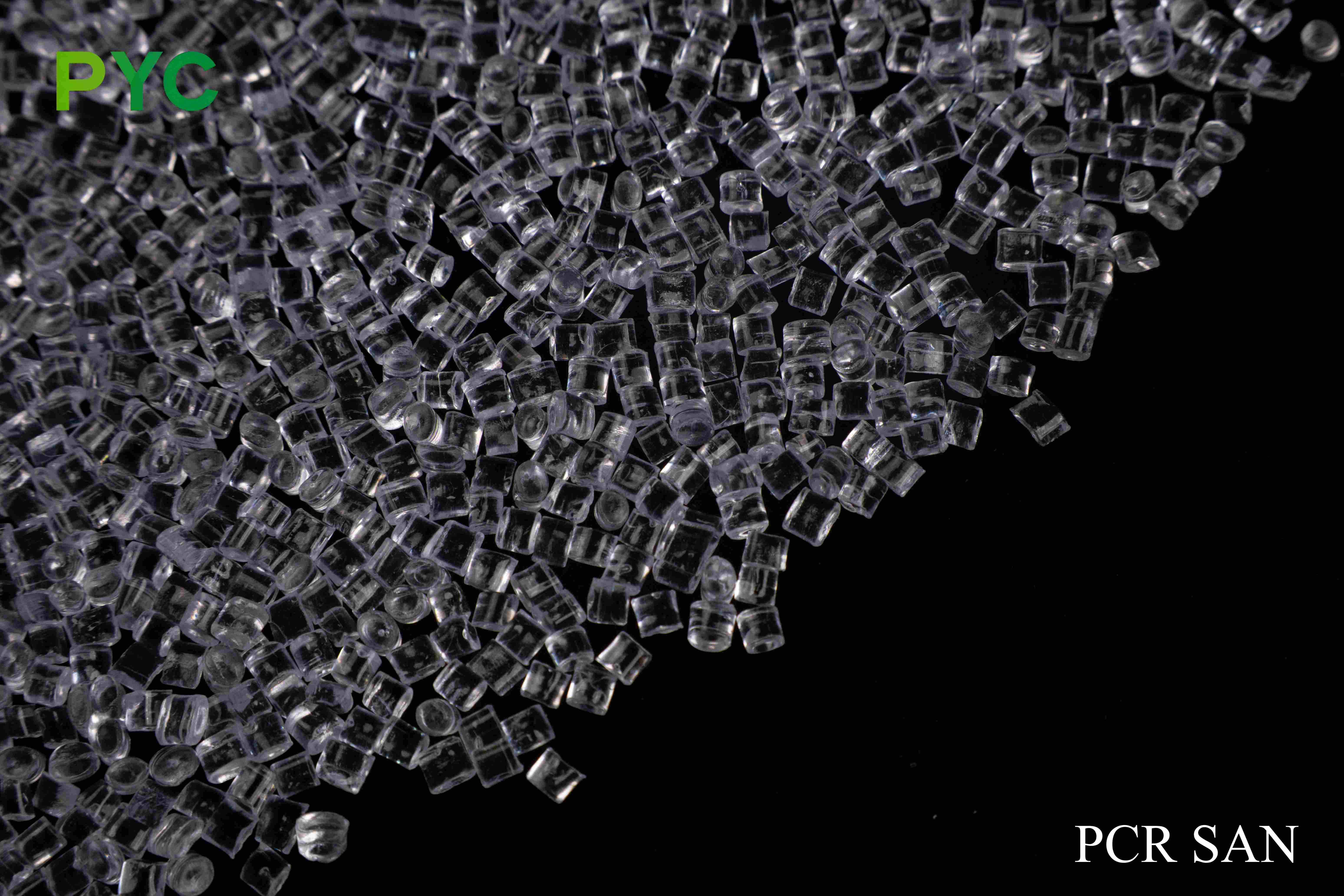

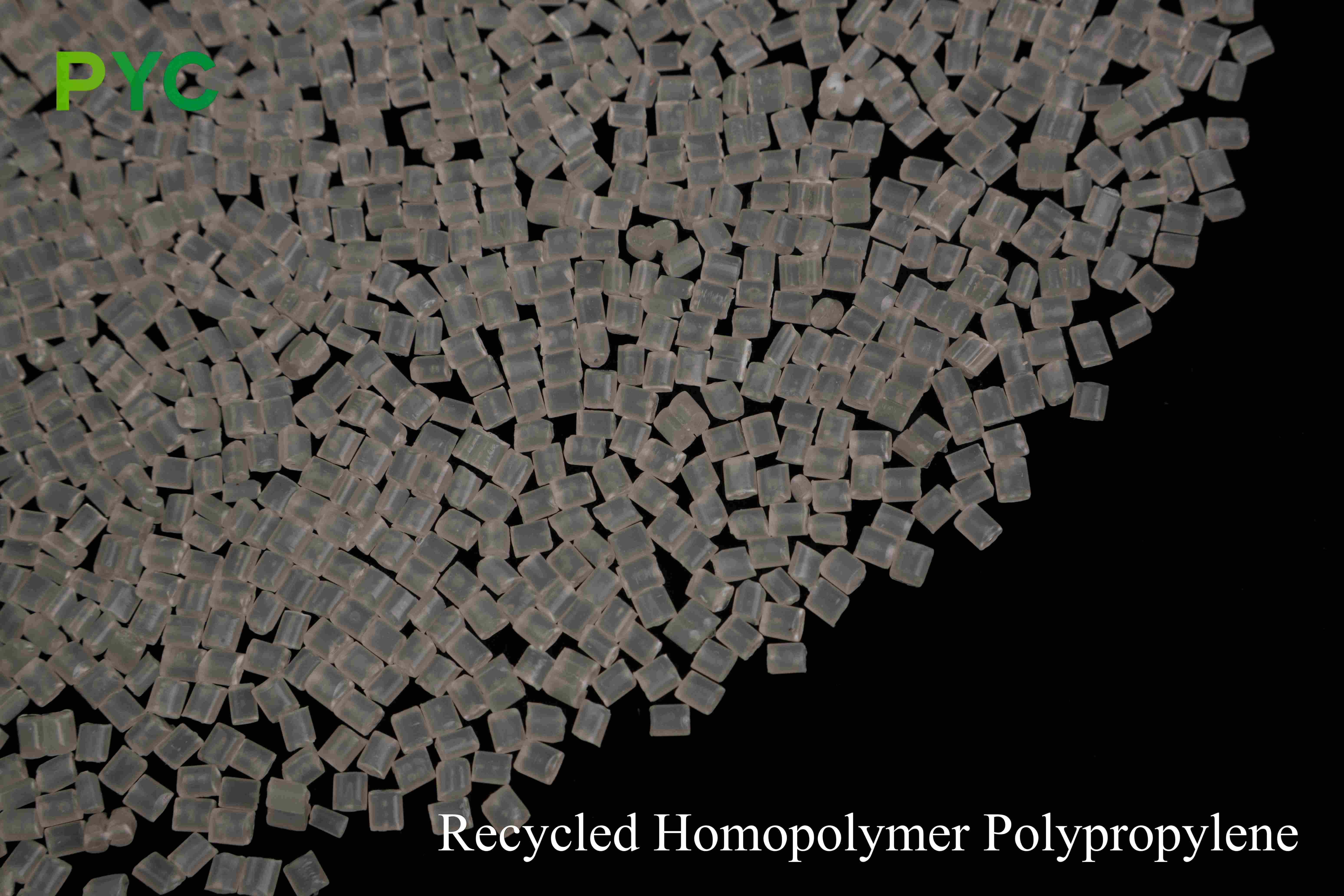

PCR MABS

PCR MABS (Post-Consumer Recycled Methacrylonitrile Butadiene Styrene Copolymer) is a recycled material made from post-consumer discarded MABS products after recycling, treatment and reprocessing. Due to its excellent transparency, impact resistance and good processing properties, MABS material is widely used in appliance housings, electronic products, automobile interiors and other fields.

Product Details

Below are the sources of high quality recycled raw materials for PCR MABS and their specific descriptions:

1. Waste appliance casings

MABS materials are commonly used in the manufacture of housings for household appliances, such as washing machines, refrigerators, and microwave ovens. These discarded appliance housings are an important source of high quality PCR MABS.

Recycling Source Example:

Washing machine housings: Discarded washing machine housings can be recycled.

Refrigerator shells: Discarded refrigerator shells are also one of the raw materials for recycling.

Microwave Oven Housings: Waste microwave oven housings can be used as a feedstock for MABS recycling.

2. Waste electronics housings

MABS materials are widely used in the manufacture of housings for electronic products, such as computers, printers, monitors, and so on. These discarded electronics housings are recycled and processed as a source of raw material for high quality PCR MABS.

Recycling Source Example:

Computer casings: Waste computer casings can be recycled.

Printer casings: Discarded printer casings are also one of the raw materials for recycling.

Monitor housings: Waste monitor housings can be used as a raw material for MABS recycling.

3. Waste automobile interior parts

MABS materials are commonly used in the manufacture of automotive interior parts, such as instrument panels and door panels. These discarded automotive interior parts are an important source of high quality PCR MABS.

Recycling Source Example:

Dashboards: Discarded automobile dashboards can be recycled.

Door panels: Discarded car door panels are also one of the recycled raw materials.

Recycling process

The recovery and processing of high-quality PCR MABS typically includes the following steps:

Collection and Sorting: Waste MABS products are collected and sorted according to material and degree of contamination.

Cleaning and Pretreatment: The recovered MABS material is cleaned to remove impurities and contaminants, and decolorized if necessary.

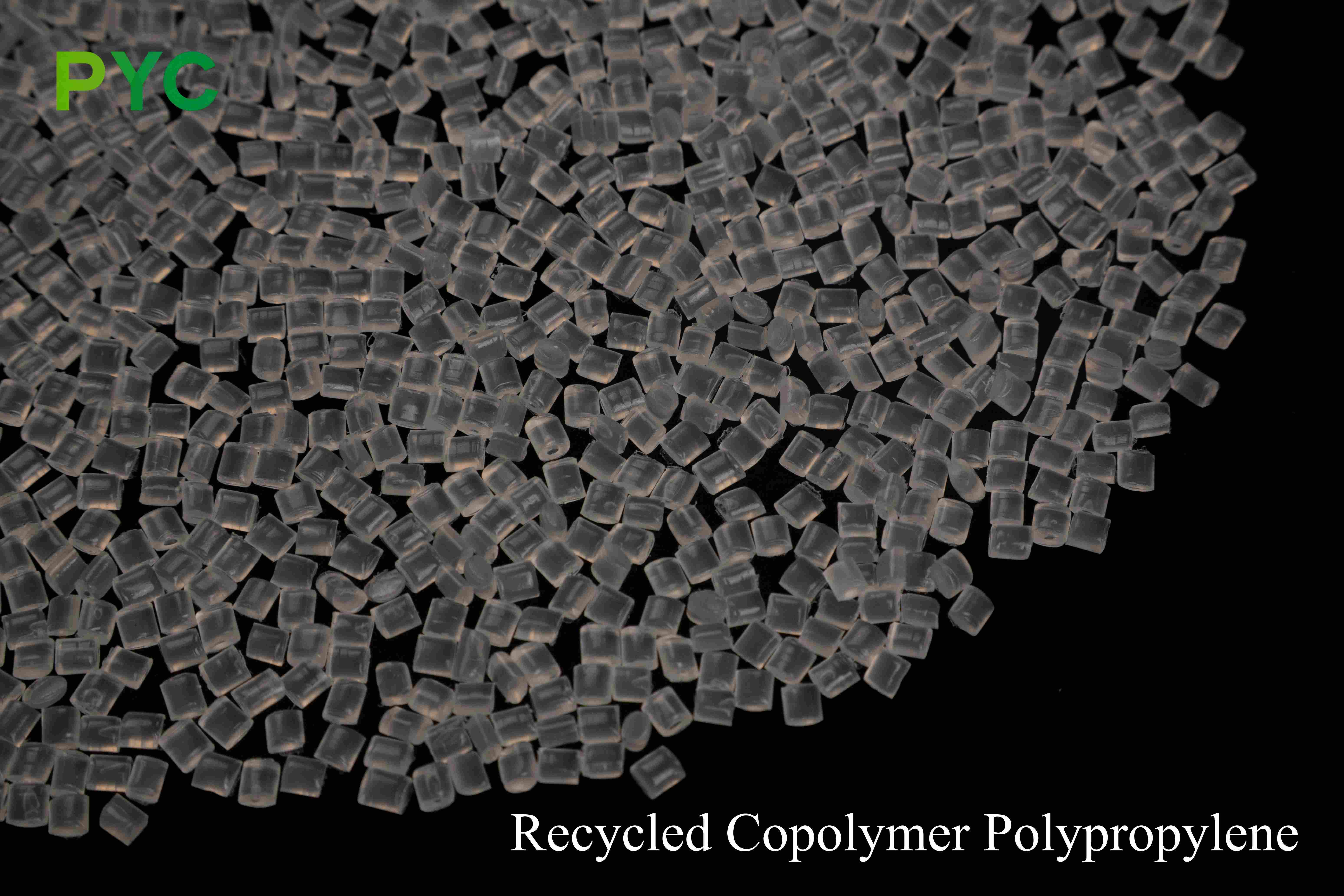

Pulverizing and melting: The cleaned MABS material is pulverized and subsequently processed into recycled pellets through a melting process.

Precision filtration: Advanced filtration technology is used to remove tiny impurities in the molten MABS to ensure the purity of the recycled material.

Quality testing: quality testing of recycled pellets to ensure that their performance meets the relevant standards and application requirements.

Industrial Applications:

In some industrial sectors, PCR MABS are used as a material for pipes, containers, and other durable parts, suitable for environments where strength and chemical resistance are required.

Product properties and benefits

High impact resistance: PCR MABS has a high impact resistance in various environments, which can effectively protect the product from damage.

High transparency: With good transparency, can enhance the appearance of the product, suitable for transparent packaging and visual display.

High temperature and chemical resistance: can maintain stability in high temperature environment, with strong chemical resistance, suitable for some harsh environment applications.

Environmental protection and sustainability: The use of recycled materials to produce, in line with global environmental standards, help reduce the accumulation of plastic waste, promote the recycling of resources.

Production and technical advantages

Recycling process: In the production process of PCR MABS, advanced recycling technology is used to ensure that high-quality recycled materials can be fully utilized, reducing the need for new resources.

Excellent processing performance: The processing performance of PCR MABS is very good, suitable for injection molding, extrusion, blow molding and other processing methods to meet different industrial needs.