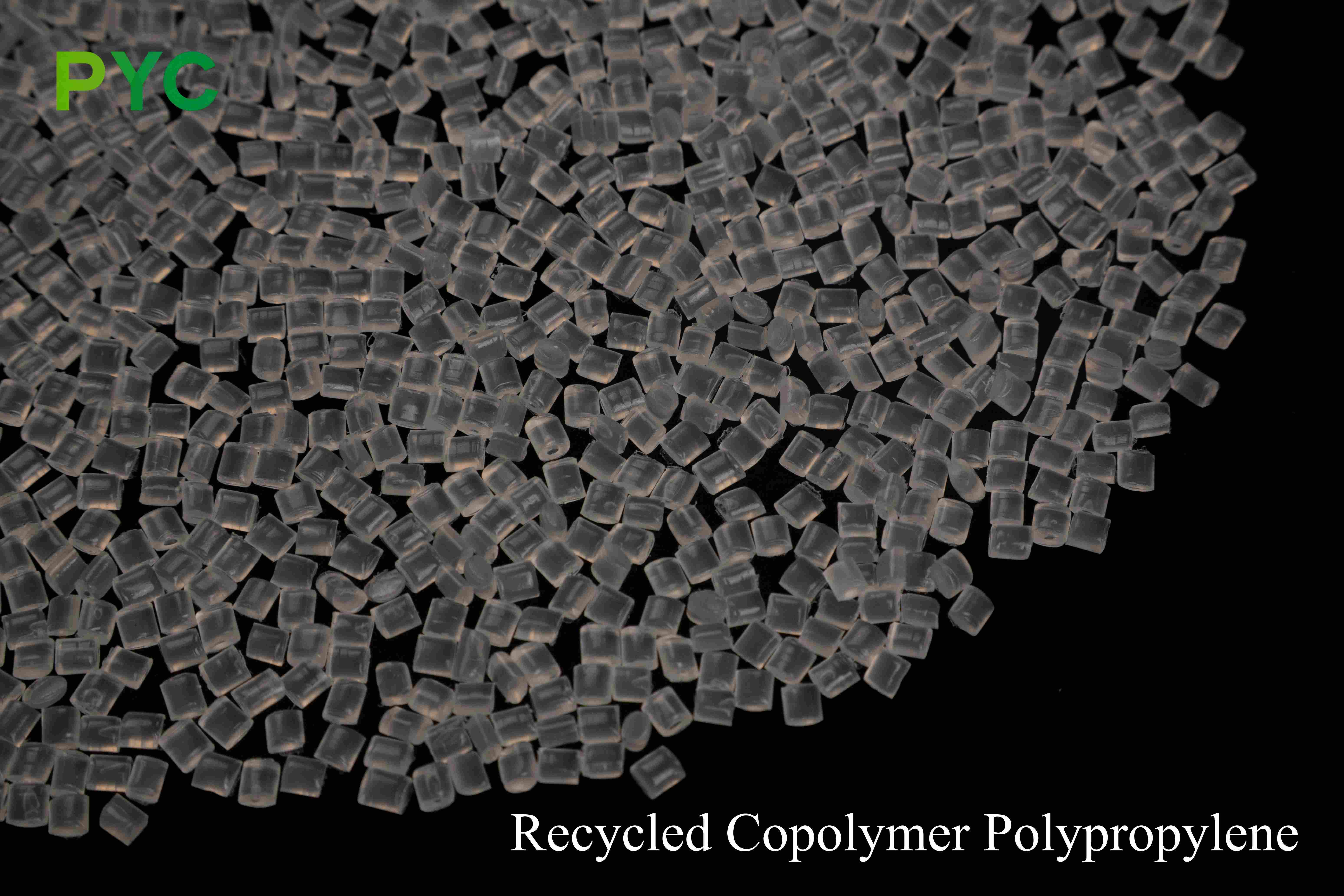

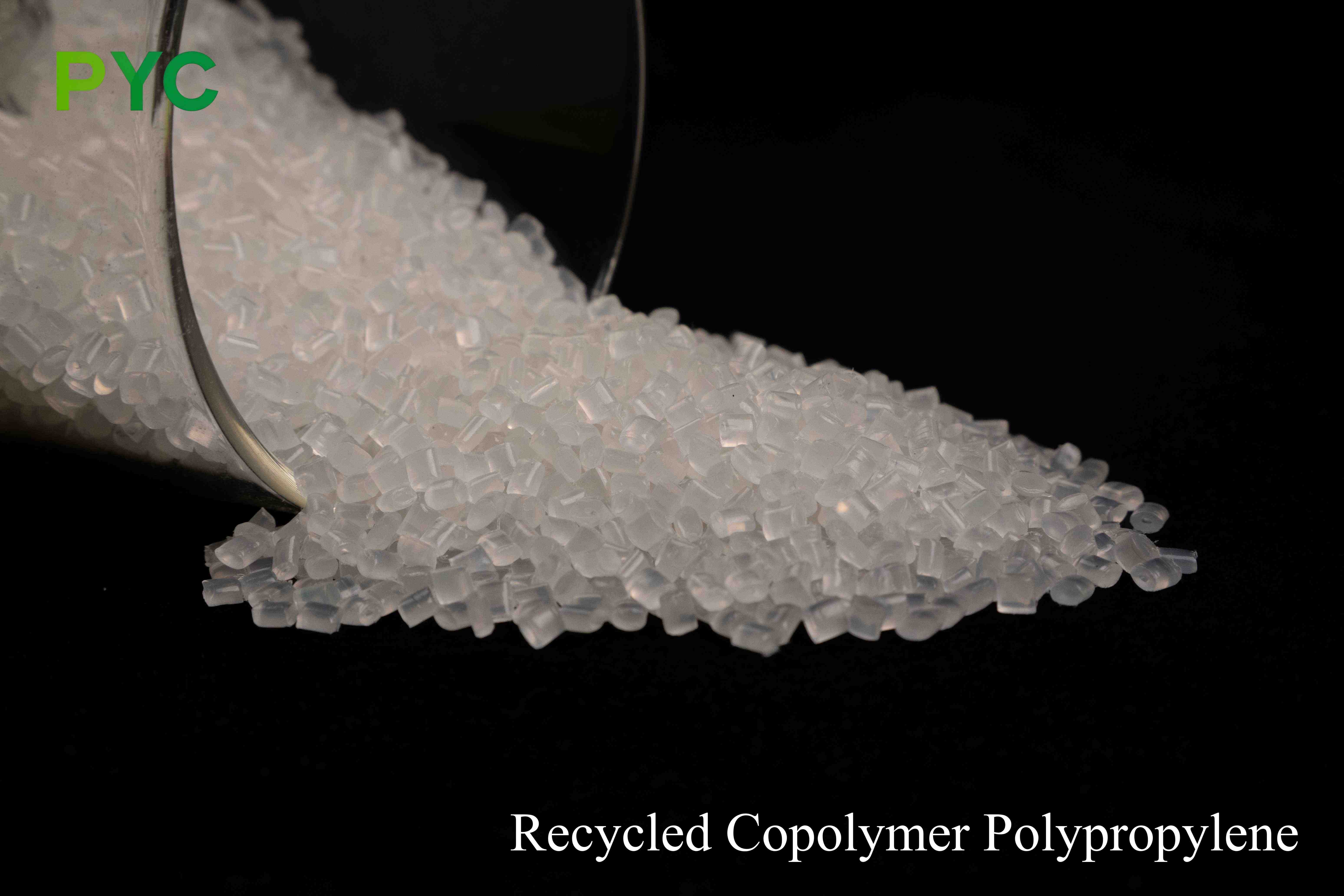

Recycled Copolymer Polypropylene

Recycled Copolymer Polypropylene is a sustainable and cost-effective material with good impact resistance and processability. It is suitable for automotive parts, home appliances, packaging, and injection molding. Available in injection molding and extrusion grades.

Details about products

High quality recycled materials

Source of raw materials and their specific descriptions:

Scrap car parts

Copolymer polypropylene is widely used in automotive manufacturing to produce components such as bumpers, dashboards and door panels. These parts can be recycled after the car is scrapped as a source of raw materials for high-quality recycled copolymer polypropylene.

Examples of recycled sources:

Car bumpers: The bumpers of end-of-life vehicles are usually made of copolymer polypropylene, which can be recycled for recycling.

Dashboards: Car dashboards are also an important application area for copolymer polypropylene, which can be used as recycled raw materials after being discarded.

Housing for household appliances

The shell of many household appliances is made of copolymer polypropylene material. These discarded electrical casings are recycled and can be used as a raw material source of high-quality recycled copolymer polypropylene.

Examples of recycled sources:

Washing machine shell: A washing machine whose useful life has expired or is damaged, the shell is usually made of copolymer polypropylene, which can be recycled for recycling.

Refrigerator linings: Discarded refrigerator linings are also a great source of copolymer polypropylene recycling.

Plastic packaging materials

Copolymer polypropylene is widely used in the manufacture of various packaging materials, such as food packaging, pharmaceutical packaging and so on. These discarded packaging materials are an important source of recycled copolymer polypropylene.

Examples of recycled sources:

Food packaging box: Disposable food packaging box can be recycled after use.

Used household items

Many household items, such as plastic furniture, storage bins, etc., are made of copolymer polypropylene. These discarded household items are recycled and can be used to produce high-quality recycled copolymer polypropylene. Examples of recycled sources:

Plastic chairs: Discarded plastic chairs can be used as raw materials for copolymer polypropylene recycling.

Storage bins: Broken or discarded plastic storage bins are also a source of recycling.

Recycling process

The recycling process of recycled copolymer polypropylene usually includes the following steps:

Collection and sorting: The waste copolymer polypropylene products are collected and sorted according to the material and the degree of contamination.

Cleaning and disinfection: The recycled plastics are cleaned to remove impurities and contaminants and, if necessary, disinfected.

Crushing and granulation: The cleaned plastic is crushed and then processed into pellets by a granulator.

Quality inspection: The quality inspection of the recycled particles is carried out to ensure that it meets the relevant standards and application requirements.

Strict quality control

In the production process, we strictly test the quality of each batch of recycled copolymer polypropylene to ensure its mechanical properties and appearance quality. The conventional quality control includes tensile strength, impact resistance, high temperature resistance, transparency and other tests. All products must comply with international standards to ensure that every production link meets strict quality requirements and that every product received by customers is of consistently high quality.

Excellent mechanical properties

High impact resistance: recycled copolymer polypropylene has excellent impact resistance and higher toughness than ordinary polypropylene, which is suitable for applications requiring high strength and impact resistance.

Good transparency and strength: rPP copolymer offers a higher transparency than conventional polypropylene and is suitable for applications that require high transparency and a beautiful appearance, such as the packaging industry.

Strong chemical resistance: recycled copolymer polypropylene has good chemical corrosion resistance, can resist a variety of acids and bases, fats and solvents, suitable for a variety of industrial and consumer products.

Sustainability and environmental protection

Recycled copolymer polypropylene produced from recycled polypropylene raw materials reduces the accumulation of plastic waste and reduces the dependence on petroleum resources. Compared to using fresh raw materials, rPP copolymer's production process effectively reduces carbon emissions and energy consumption, and promotes green and sustainable development.

Application Areas:

Packaging industry:

Food and beverage packaging: Because of its good transparency, strength and impact resistance, recycled copolymer polypropylene is widely used in the production of transparent food containers, beverage bottles, packaging bags, etc., which not only ensures the strength of packaging materials, but also has good aesthetics.

Flexible packaging film: suitable for the production of various flexible packaging materials, such as food bags, cling film, medicine packaging film and so on.

Automotive industry:

Interior and exterior trim parts: recycled copolymer polypropylene is used in the production of automotive interior trim parts (such as door panels, instrument panels) and exterior trim parts (such as body trim strips, bumpers, etc.), with high impact resistance and good high temperature resistance, to adapt to the needs of vehicles in different environments.

Auto parts: such as seat frame, carpet bottom and other parts, can withstand high temperature, anti-impact, extend the service life of auto parts.

Consumer goods:

Household goods: Recycled copolymer polypropylene is widely used in household products, such as storage boxes, household plastic containers, furniture accessories, etc., both durable and beautiful characteristics.

Daily supplies: including a variety of plastic bags, garbage bags, packaging boxes, etc., suitable for products that have certain requirements for durability in daily life.

Performance and advantages:

Excellent transparency: The transparency of recycled copolymer polypropylene makes it an ideal choice for the production of transparent packaging materials, and is widely used in the packaging needs of food, medicine and other industries.

Good impact resistance: it can still maintain good performance in low temperature environment, especially suitable for impact resistant packaging, automotive interior and exterior trim parts.

High chemical resistance: It has good corrosion resistance to a variety of chemicals, oils and solvents, and is suitable for the manufacture of industrial and household goods.

Production and technical advantages:

Advanced recycling technology: Through the use of efficient recycling technology, high-quality polypropylene materials can be extracted from the waste to produce high-purity recycled copolymer polypropylene. The recycling process used is carefully optimised to ensure that the properties of the material are as close as possible to the raw polypropylene.

Diverse processing processes: Recycled copolymer polypropylene can be used through injection molding, extrusion, blow molding and other processing processes to meet the needs of different application fields for product form and function.

Environmental protection and cost effectiveness:

Environmentally friendly preferred materials: Products produced with recycled polypropylene materials help enterprises reduce raw material consumption, reduce production costs, and comply with increasingly stringent environmental regulations.

Reduce production costs: recycled copolymer polypropylene has lower procurement costs, helping enterprises to ensure product quality at the same time, reduce manufacturing costs, improve market competitiveness.