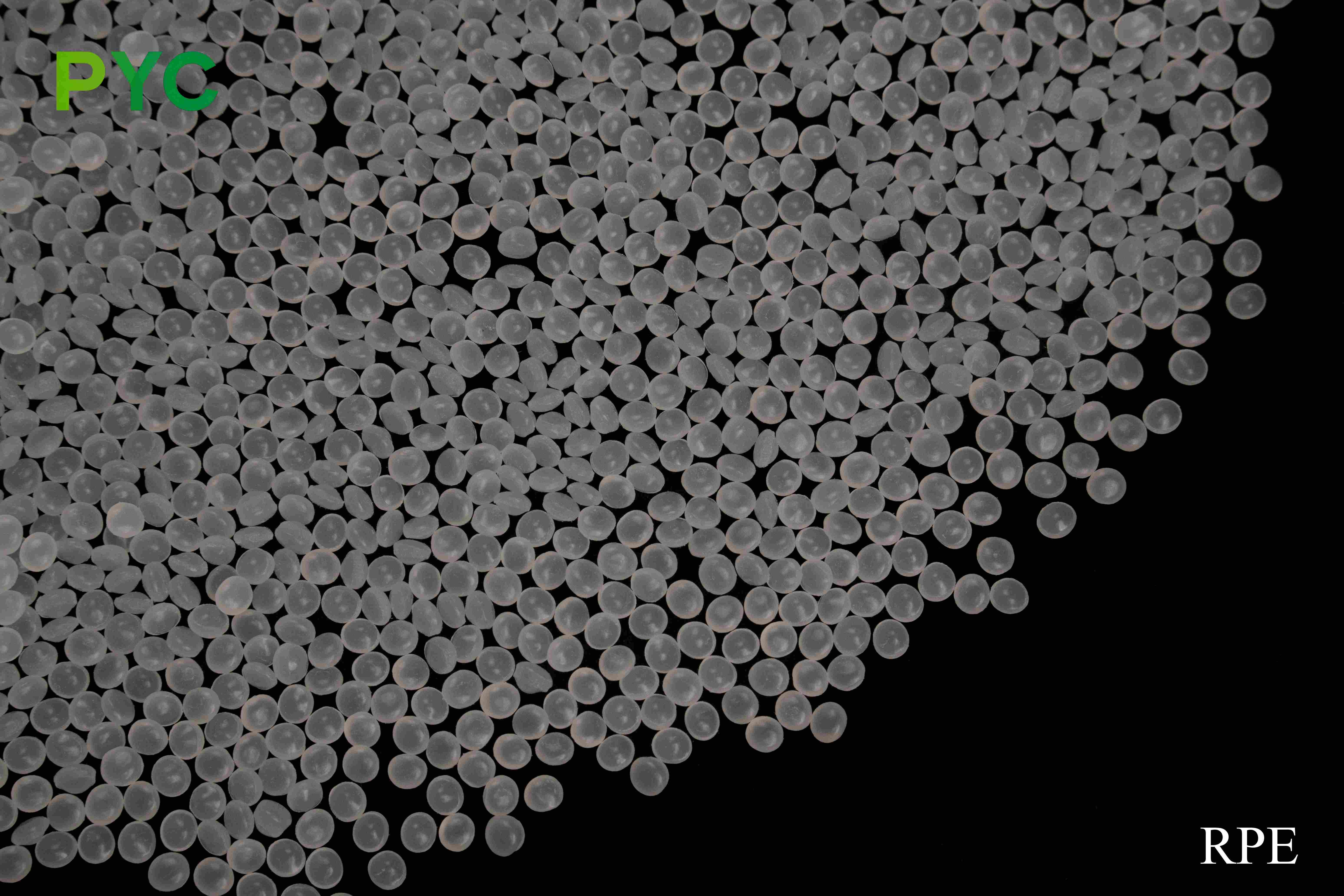

RPE

Product highlights:

High quality recycled raw materials

RPE (Recycled polyethylene) uses a single source, rigorously screened industrial recycled polyethylene (PE) raw material, mainly from the following specific recycling channels:

Blow molding waste: from discarded blow molding plastic products, such as plastic drums, containers, etc. The recycled waste is cleaned to remove contaminants and ensure high purity and low impurity content of the material.

Extruded scraps: Includes discarded extruded scraps, such as those produced during the production of polyethylene film and tubing. These wastes are strictly screened and purified to ensure stable raw material quality and very low impurities.

Unused film: From unused polyethylene film, such as packaging film or industrial film. These films are screened and cleaned to ensure that they have stable physical properties and are suitable for further processing and reuse.

Pipe: Polyethylene pipe derived from waste, mainly used in water pipes, drains and other systems. After screening and removing impurities, to ensure that the recovered material has excellent mechanical properties and stability.

All raw materials come from reliable upstream suppliers to ensure the purity and stability of the material, and reduce the content of impurities, thereby improving the physical properties of the final product, which is widely used in packaging materials, piping systems, building materials and other fields.

Strict quality control

In the process of RPE production, melt index (MFI), density, tensile strength and impact properties are tested to ensure that the material has excellent processing adaptability and mechanical properties. Its chemical corrosion resistance is strong, suitable for pipeline, packaging film, agricultural film and plastic containers and other fields, to meet the requirements of high durability and environmental protection.

Environmental protection and resource reuse:

RPE is made by recycling and treating polyethylene waste, reducing the need for new resources and in line with global environmental trends. Compared with traditional petroleum-based polyethylene, RPE effectively reduces energy consumption and carbon footprint in the production process, providing enterprises with an environmentally friendly and economical alternative material.

Excellent durability and UV resistance:

RPE maintains the weatherability and anti-ultraviolet ability of the original polyethylene, and can resist the influence of sunlight, rain and harsh climatic conditions, to ensure that its long-term use is not easy to age or damage. Suitable for long-term exposure to outdoor application environment, such as packaging film, agricultural film and so on.

Good formability and processability:

RPE has good processing properties, can be molded by injection molding, extrusion and blow molding and other ways, suitable for a variety of production processes. Whether it is to manufacture packaging bags, membrane materials or building products, RPE can maintain good physical properties and molding quality.

Multi-functional applications:

RPE is widely used in packaging, agriculture, construction and other fields. In the packaging field, it is used to produce food packaging bags, garbage bags, shopping bags, etc.; In the agricultural sector, RPE can be used as agricultural film and pipe; In the construction sector, RPE is used as a waterproof film and pipe material. Due to its durability and economy, RPE is in increasing demand in multiple industries.

Product Details:

Fields of Application:

RPE is widely used in many industries, especially in packaging and agriculture. It is often used in the production of various packaging materials, such as food bags, industrial bags, garbage bags, etc. The UV resistance of RPE allows it to maintain stable performance for a long time when used outdoors. In addition, RPE is also widely used in the agricultural field, often used in the manufacture of agricultural film, mulch, irrigation pipes, etc. Due to its better durability and environmental performance, RPE is also gradually used in the construction industry, especially in waterproof film and pipeline products.

Product performance and advantages:

RPE has excellent durability, UV resistance and weather resistance, and can maintain stable performance under long-term exposure to environmental factors such as sunlight and rain. Its molding performance is good, and it can be produced by different processing processes to meet the needs of different fields. The recycling characteristics of RPE give it a significant advantage in reducing plastic waste and reducing production costs, and at the same time, its environmental protection characteristics also comply with increasingly stringent environmental regulations.

Production and technical advantages:

In the production process of RPE, advanced recycling technology is adopted, and the waste polyethylene material is effectively utilized through optimized regeneration process and fine processing, and the produced RPE maintains high mechanical properties and physical characteristics. In the production process, energy saving and emission reduction reduce the waste of resources, in line with the concept of green production. RPE can be processed through a variety of processing methods to adapt to different industry needs.

Environmentally friendly and cost effective:

By recycling polyethylene waste in the production process, RPE not only reduces the demand for natural resources, but also reduces carbon dioxide emissions, in line with global environmental protection and sustainable development requirements. At the same time, the production cost of RPE is lower than that of traditional new materials, so it is able to bring significant cost benefits to companies. In addition, the regenerative nature of RPE materials also makes it an ideal choice for an increasing number of companies when it comes to meeting their environmental goals.

With its environmental performance, excellent physical properties, as well as a wide range of applications, RPE is gradually becoming a favored recycled material in the market. It not only helps to promote resource reuse and sustainable development, but also provides enterprises with an economical and environmentally friendly solution that meets the dual needs of various industries for material performance and cost.