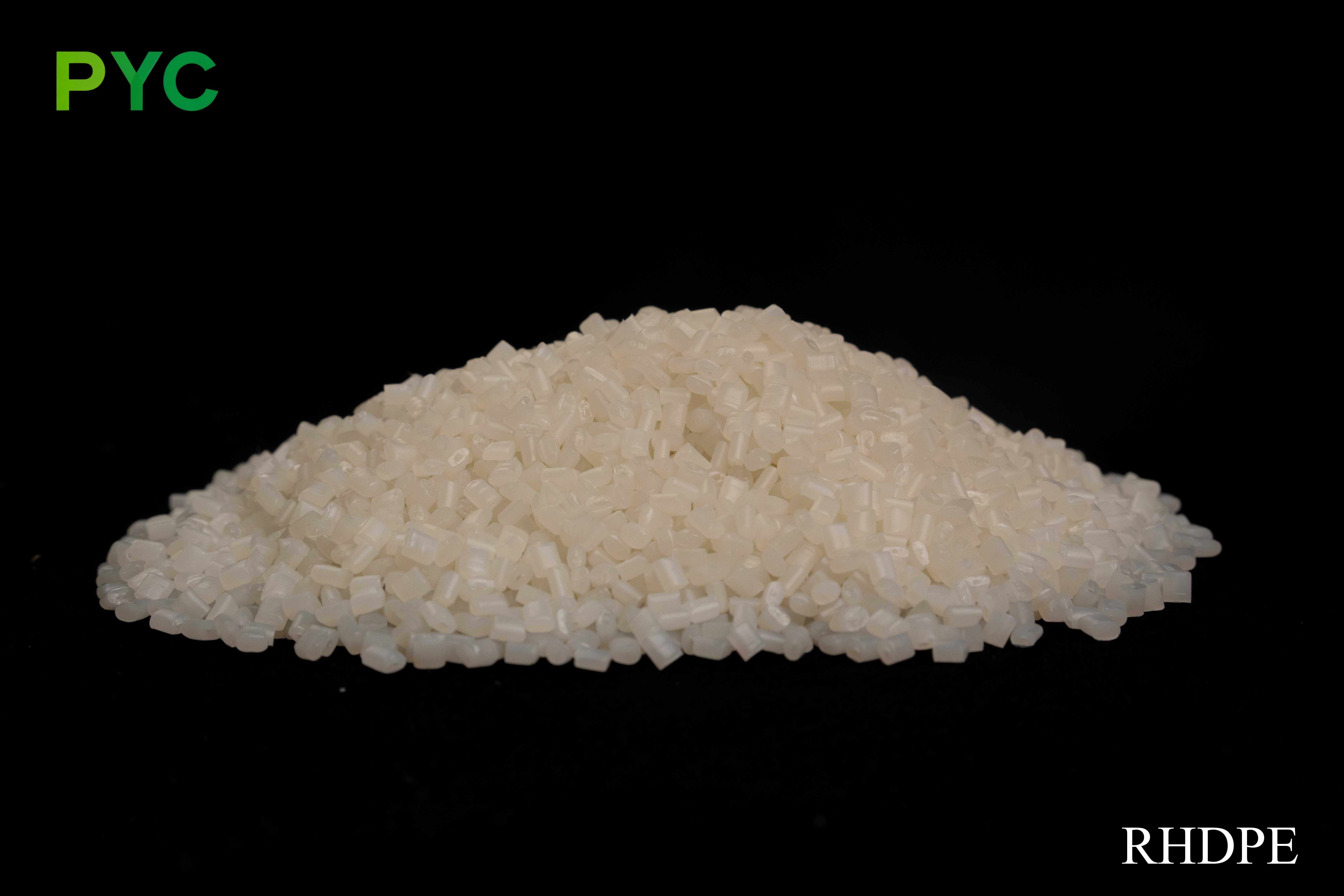

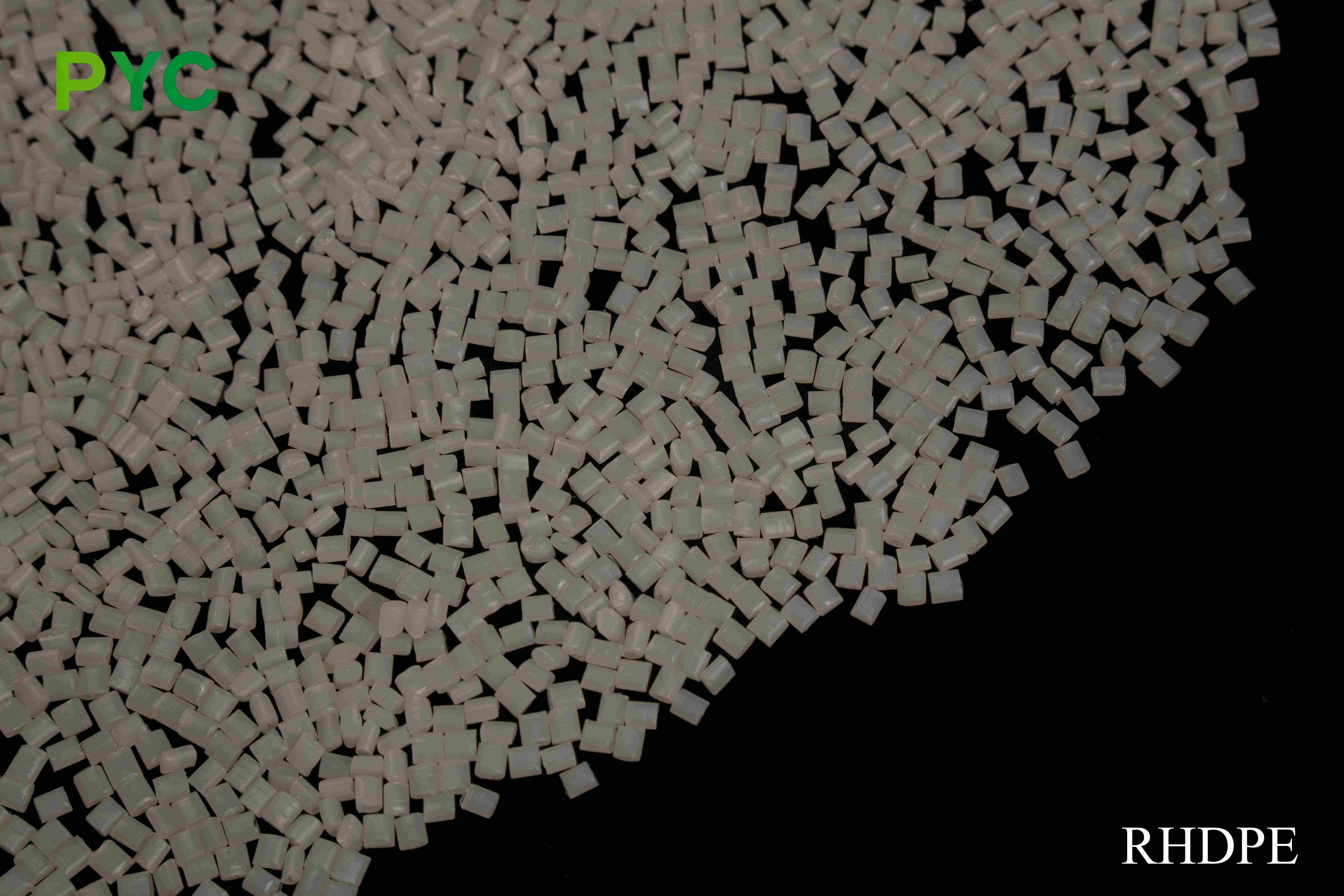

RHDPE

Product highlights:

High quality recycled raw materials

RHDPE (Recycled High Density Polyethylene) uses a single source, carefully screened industrial recycled HDPE raw material, mainly from the following specific recycling channels:

Blow drums: Plastic blow drums from waste, which are often used to store chemicals, food or other industrial products. Discarded blow molding drums, after cleaning and removing labels and other impurities, guarantee high purity of the material and low impurity content.

Tubing: Derived from discarded HDPE tubing, mainly used in water supply and drainage systems. These pipes are rigorously screened during the recycling process to remove contaminants and ensure that the recycled material has excellent mechanical properties and stability.

Sheets: HDPE sheets are derived from waste and are often used for packaging, construction or other industrial purposes. These sheets are carefully screened and cleaned to ensure no pollution and impurities, and maintain high quality and stable physical properties.

Injection molding waste: includes the waste from the injection molding process of HDPE, such as the scraps generated during the production process and unused molded parts. All waste is carefully screened to ensure extremely low impurity content, ensuring the mechanical properties and long-term stability of the product.

With high-quality recycled HDPE raw materials collected from these reliable sources, RHDPE is able to provide a high-strength, durable end product that is widely used in packaging materials, plumbing systems, construction materials and many other fields.

Strict quality control

RHDPE is tested for melt index (MFI), tensile strength, impact toughness and chemical resistance in the production process to ensure its excellent durability and stability. Its high rigidity, corrosion resistance and good processing adaptability make it widely used in pipelines, storage tanks, pallets, automotive parts and modified masterbatch and other fields.

Environmental protection and sustainability:

RHDPE is made from recycled plastic, greatly reducing the consumption of raw materials and the environmental impact of waste. By recycling waste plastic products, RHDPE becomes a green and environmentally friendly material. It not only complies with increasingly stringent environmental regulations around the world, but also provides a sustainable solution for companies' green production.

Excellent chemical and weather resistance:

RHDPE has excellent resistance to most chemicals such as acids, bases and salts, making it suitable for applications such as chemical storage, piping and containers. It also exhibits good ultraviolet (UV) resistance, which makes RHDPE stable and resistant to aging even after long-term exposure in outdoor environments.

High strength and impact resistance:

Compared to other recycled plastics, RHDPE has a high strength and hardness, especially suitable for high load and high impact environments. Whether used as a support structure for building materials or as a shell for containers, RHDPE provides reliable performance and ensures product stability and durability.

A wide range of applications:

RHDPE can be used in many different application areas such as packaging, piping, containers, furniture, agricultural equipment, etc. In the packaging industry, RHDPE is often used to make durable bottles, drums, and containers; In the construction industry, it can be used in the production of plastic pipes, window frames and other materials; In the agricultural sector, it is widely used in greenhouse covers, irrigation systems and other equipment, giving full play to its high weather resistance and mechanical strength.

Product Details:

Multifunctional applications:

RHDPE is widely used in many industries, especially in areas with high requirements for durability and environmental protection. For example, in the packaging industry, RHDPE is often used to produce high-capacity containers and drums suitable for storing liquids, chemicals, etc.; In the construction industry, RHDPE is used as pipes, building panels, and waterproof membranes, providing high strength and long-term stability. In the agricultural sector, RHDPE's high weather resistance makes it the material of choice for irrigation pipes, greenhouse films, and agricultural packaging. In addition to these primary applications, RHDPE can also be used to manufacture household goods and industrial equipment for many different needs.

Product Features and Benefits:

One of the main advantages of RHDPE is its excellent chemical resistance, which can withstand the attack of various acids, bases and salt chemicals without damage or loss of original properties due to exposure to chemicals. In addition, RHDPE performs well in weather resistance, has strong resistance to ultraviolet rays, and can also retain its physical properties and strength for a long time in outdoor environments, and is widely used in facilities exposed to the outdoors, such as water storage facilities, construction materials and agricultural equipment.

Production and technical advantages:

The production of RHDPE uses advanced recycling technology and optimized processing technology to ensure the high quality of the final product through precision screening and treatment of discarded high-density polyethylene materials. The use of modern production equipment and strict quality management system enables RHDPE to maintain stable performance in the processing process and meet customers' demand for high-quality, mass production. In addition, the processing performance of RHDPE is good, and it can be processed by injection molding, extrusion and other ways to meet various production needs.

Environmental protection and cost effectiveness:

As a recycled material, RHDPE effectively reduces the cost of producing new materials while reducing the environmental impact of plastic waste. The environmentally friendly nature of RHDPE allows it to meet increasingly stringent environmental standards and is an ideal material for enterprises to reduce production costs while pursuing sustainable development. In addition, RHDPE not only has excellent durability, but also does not cause additional burden to the environment after a long time of use, further improving its environmental benefits.

RHDPE has become one of the most popular materials in the market due to its excellent performance, environmental benefits and wide range of application scenarios. Whether it is to resist chemical corrosion, resist UV aging, or provide high-strength industrial components, RHDPE offers the ideal solution to help companies achieve a balance between performance and environmental protection in multiple industries.