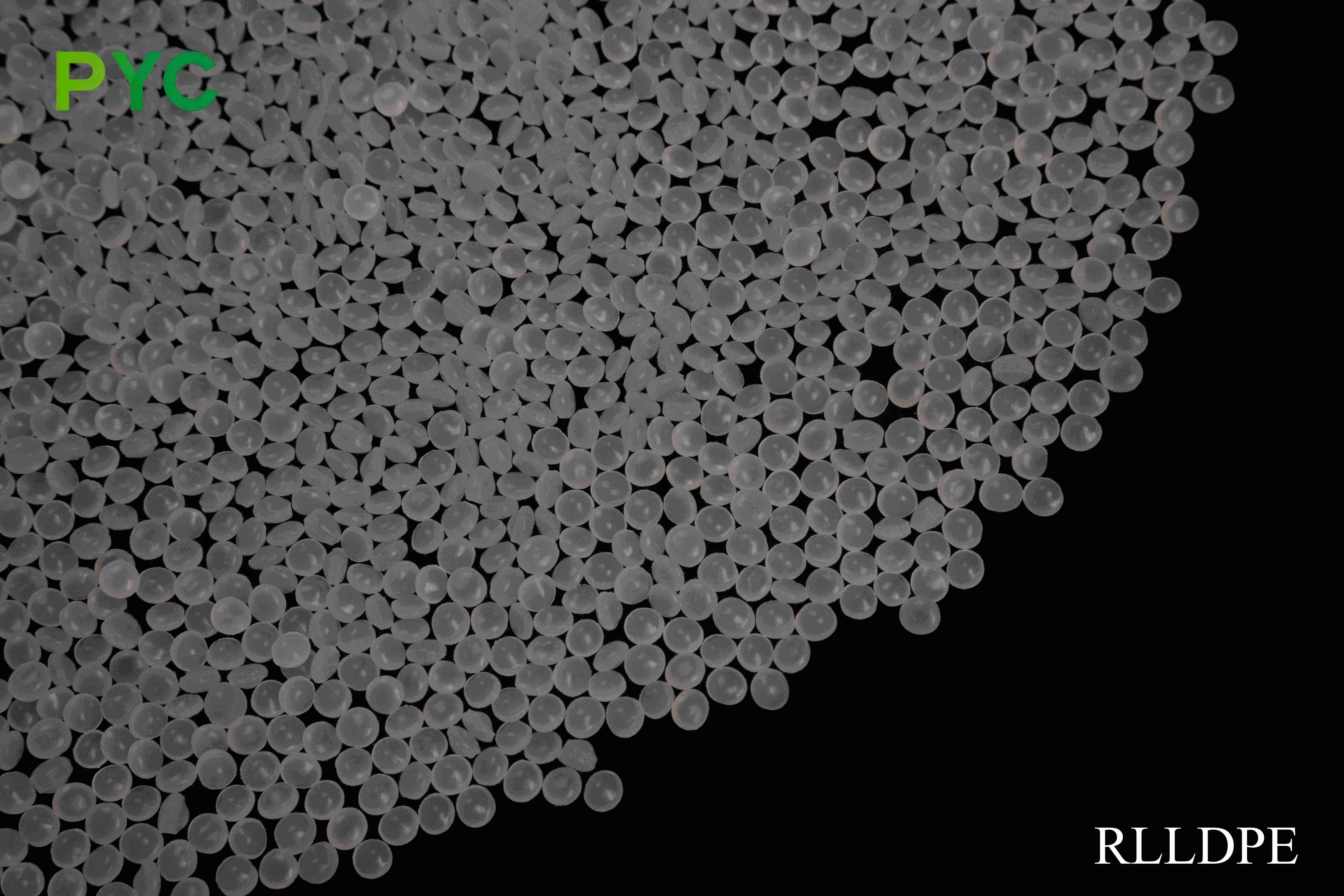

RLLDPE

Product highlights:

High quality recycled raw materials

RLLDPE (Recycled Linear Low Density Polyethylene) uses a single source, carefully screened industrial recycled LLDPE raw material, mainly from the following specific recycling channels:

Cast film: cast film derived from waste, often used for packaging and surface protection. After strict screening and cleaning treatment, to ensure the high purity of the material and low impurity content, to maintain its excellent processing stability.

Packaging film: from the discarded LDPE/LLDPE packaging film, these films are commonly used for the packaging of various products. The recycled film is carefully screened to remove inks and contaminants, ensuring excellent mechanical properties of the material.

Agricultural mulch: Derived from waste LLDPE mulch used in agriculture, such as those used for farmland mulch. It is rigorously screened and cleaned to ensure the purity and stability of the material and is suitable for a variety of recycling applications.

Pipe scraps: Includes discarded LLDPE pipe scraps, which are mainly derived from leftover materials from the pipe manufacturing process. These scraps are screened and purified to ensure extremely low impurity content and good processing adaptability.

Through strict screening and purification treatment, RLLDPE is able to provide high quality recycled materials, which are widely used in packaging film, agricultural film, pipeline system and other fields, with excellent processing stability and mechanical properties.

Strict quality control

RLLDPE carries out melt index (MFI), tensile strength, impact toughness and environmental stress cracking (ESCR) testing during the production process to ensure product stability and durability. Its excellent flexibility, tear resistance and weather resistance make it widely used in blow molding film, agricultural film, pipe, packaging and modified masterbatch and other fields.

High tensile properties and flexibility:

RLLDPE has high tensile strength and excellent flexibility, which is especially suitable for the production of films, bags and other materials that need both durability and tensile property. Whether it is food packaging or industrial packaging, RLLDPE offers excellent flexibility and load carrying capacity.

Impact resistance and low temperature resistance:

RLLDPE maintains excellent mechanical properties at low temperatures, making it particularly suitable for use in cold regions or extreme climates. Its impact resistance also gives it greater durability during transportation and storage, effectively preventing product damage.

Environmental protection and Sustainability:

As a recycled material, RLLDPE helps reduce the build-up of plastic waste and meets global environmental standards. In its production process, resources are fully reused, which not only saves raw materials, but also reduces the carbon footprint in the production process, making it an ideal material to support the sustainable development of enterprises.

Wide application areas:

RLLDPE can be used in a variety of industries, especially packaging. It is widely used in the manufacture of food packaging bags, industrial packaging films, shopping bags, etc. In addition, RLLDPE can also be used in agricultural fields, such as agricultural film and irrigation pipes, with good UV resistance linearity and weather resistance. Its high stretchability and flexibility make it ideal for packaging materials that need to be durable and strong.

Product Details:

Application field:

RLLDPE has a wide range of applications, especially in the packaging industry is widely used. It is used in the production of various packaging materials, including food packaging bags, industrial packaging films, shopping bags, garbage bags, etc. These materials not only have strong durability, but also have better transparency and flexibility. In addition, RLLDPE is also commonly used in the agricultural field, mainly as agricultural film, mulch, irrigation pipes and other production materials. Its excellent UV resistance linearity, low temperature resistance and chemical resistance make it maintain excellent performance in outdoor environment.

Performance and advantages:

RLLDPE material has excellent tensile properties and high impact resistance, making it excellent in applications. Its flexibility, low temperature resistance and strong UV resistance make it particularly suitable for outdoor applications. Whether used in packaging, agriculture or industry, RLLDPE provides long-term stable performance, ensuring that it will not be damaged by external factors in harsh conditions.

Production and Technical advantages:

The production of RLLDPE adopts advanced recycling technology, and transforms waste polyethylene materials into high-quality new materials through fine recycling and reprocessing process. In this process, RLLDPE is able to retain high mechanical properties and physical properties, enabling it to play a role in a variety of applications. With a variety of processing methods such as injection molding, extrusion and blow molding, RLLDPE can be adapted to different production needs and maintain its excellent characteristics during processing.

Environmentally friendly and cost effective:

As a recycled material, RLLDPE greatly reduces the generation of plastic waste during the production process, which has significant environmental advantages. Compared with the use of new materials, the production of RLLDPE not only saves raw materials, but also reduces energy consumption and reduces production costs. Its environmentally friendly nature and sustainable development characteristics make it an ideal choice in line with the concept of green production and environmental protection policies.

RLLDPE with its high tensile, flexibility, impact resistance and environmental protection advantages, widely used in packaging, agriculture, industry and other industries, has become a growing market demand for recycled materials. Through continuous innovation and technical optimization, RLLDPE can not only meet the strict industry standards, but also promote the overall improvement of enterprises in environmental protection and cost efficiency.