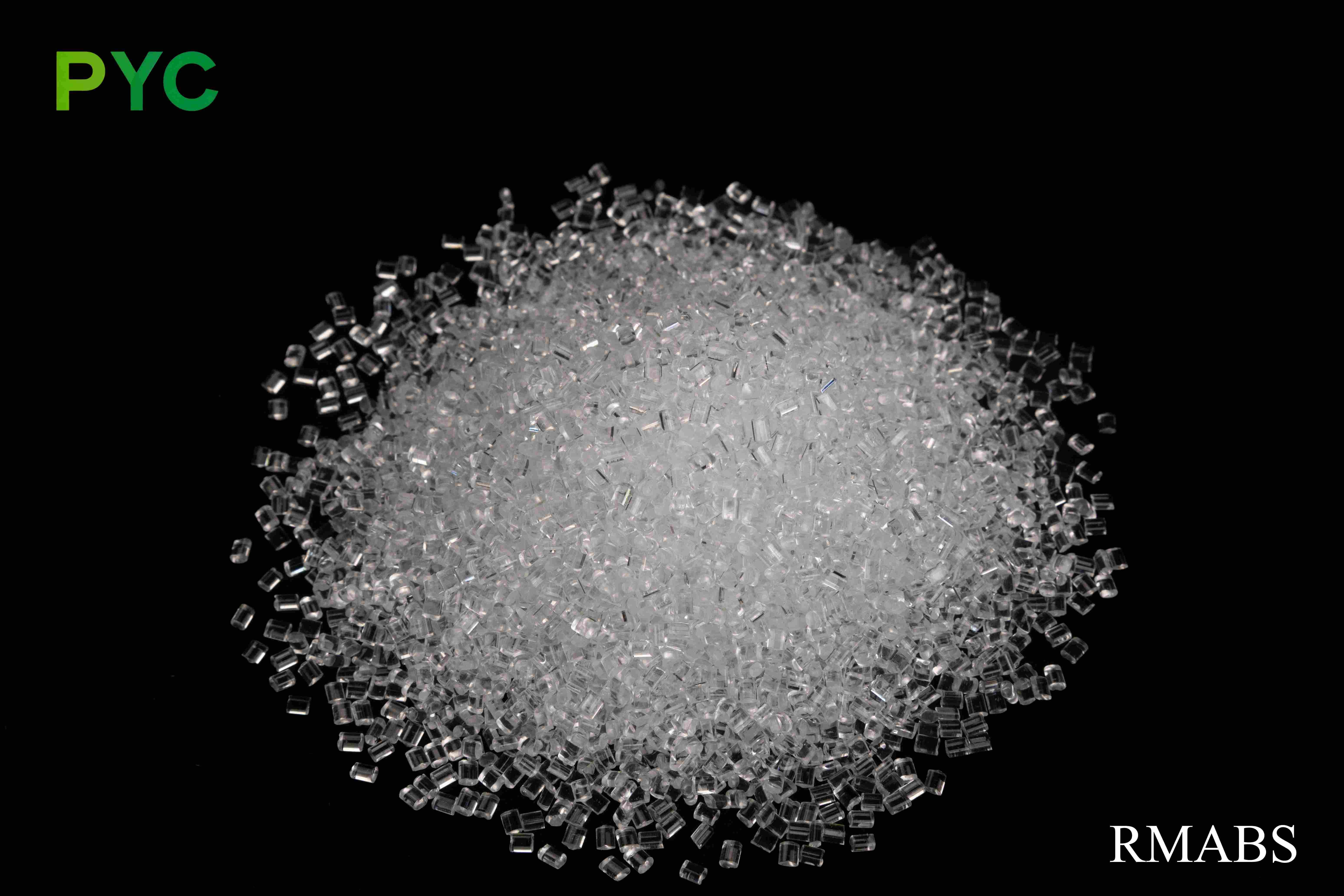

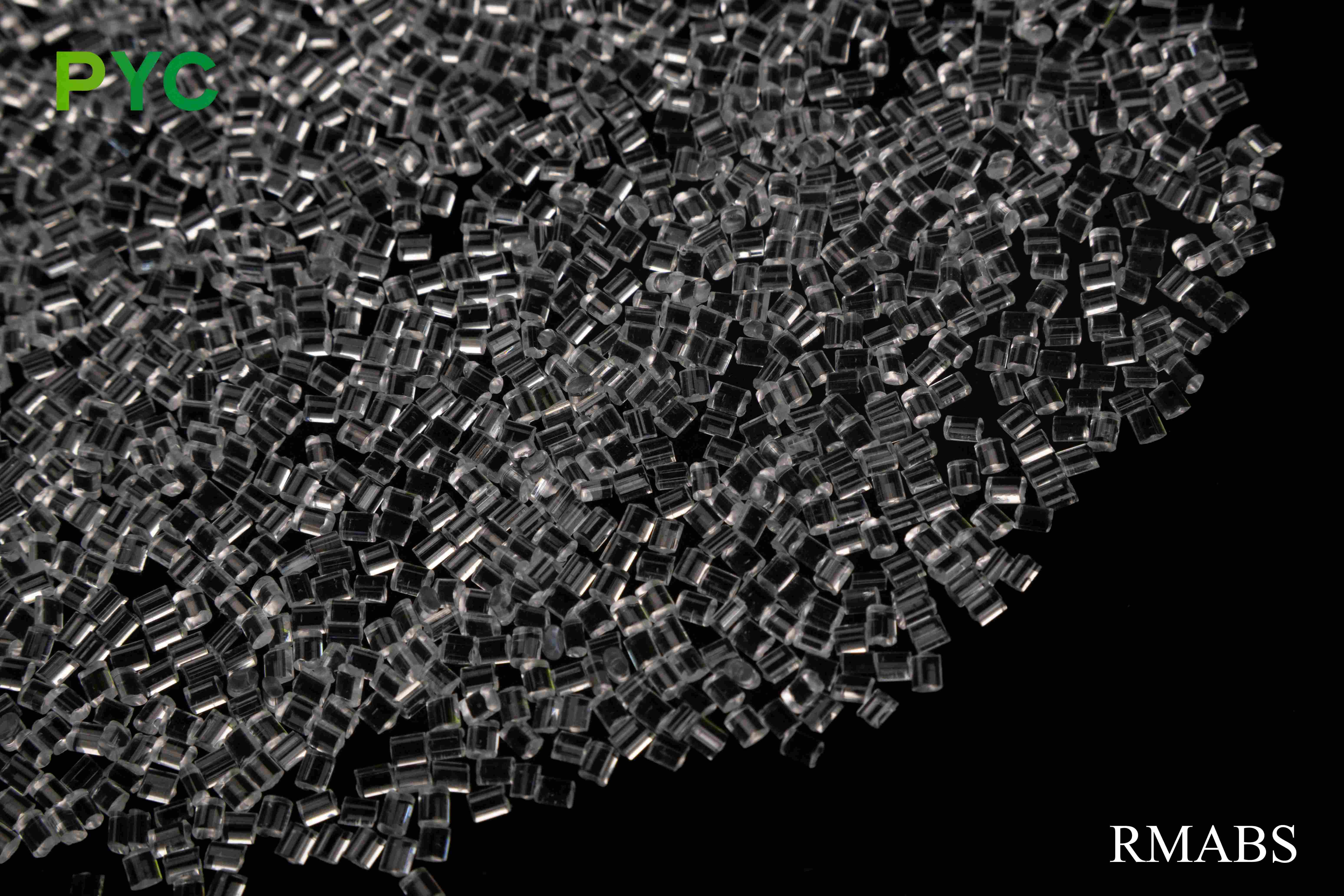

RMABS

Product Highlights

Selected recycling sources: RMABS uses high-purity recycled ABS raw materials, mainly from post-consumer recycling (PCR) plastics and industrial recycling (PIR) plastics.

PCR ABS: Recycled post-consumer plastics from electronic products, home appliance housings, automotive parts, etc., are carefully sorted, cleaned and granulated to ensure high purity and stable performance.

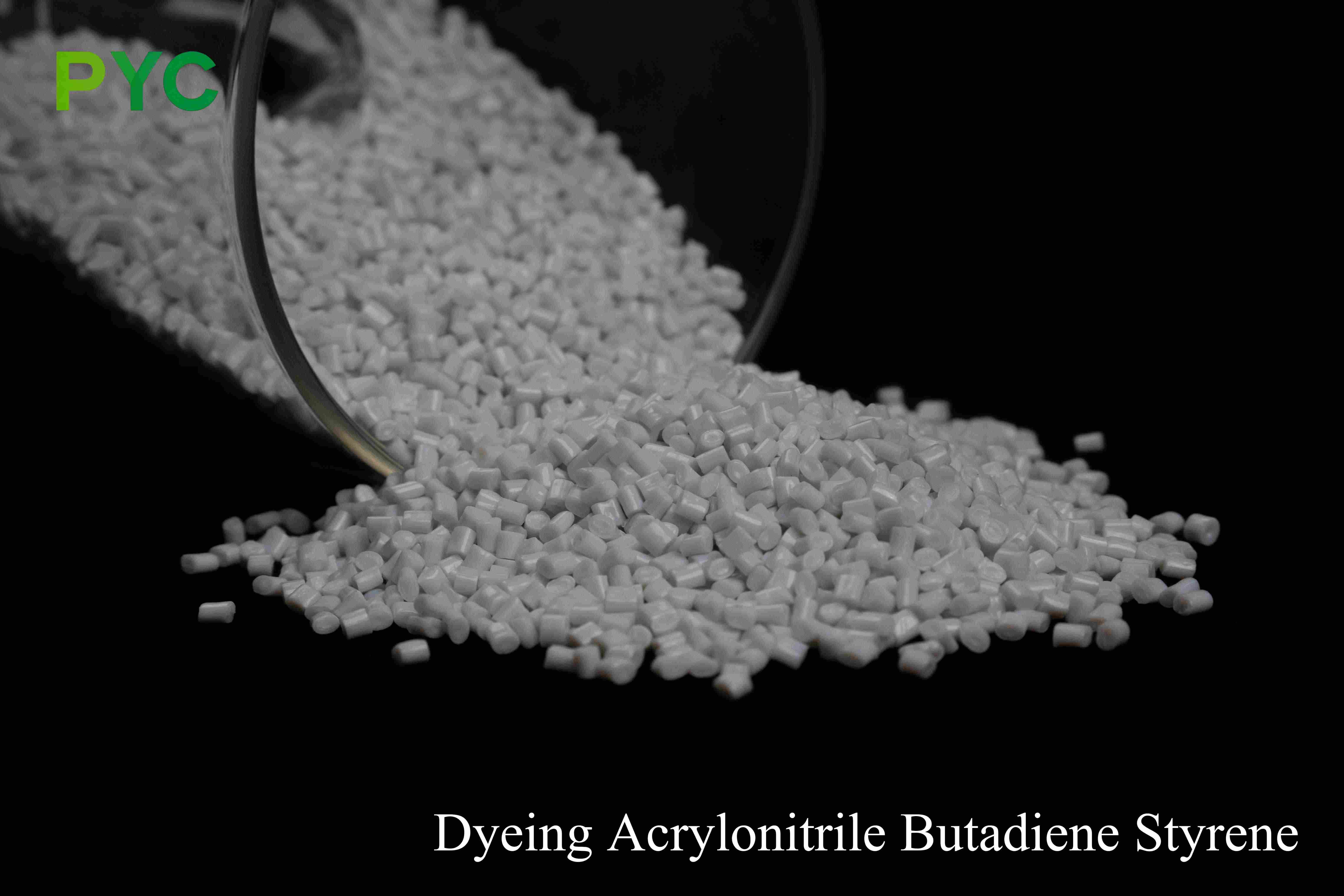

PIR ABS: Scraps and scrap materials from manufacturing plants that are recycled before they reach the consumer market, reducing waste while maintaining excellent mechanical properties.

High standard screening: All recycled raw materials undergo a rigorous sorting, impurity removal and re-granulation process to ensure low impurity content and controlled color difference to meet the needs of high-end applications.

High impact resistance: RMABS offers excellent impact resistance and excellent durability even at low temperatures, making it suitable for applications with high strength requirements.

Good processing performance: can be used in injection molding, extrusion, thermoforming and other processing methods, compatible with existing ABS production equipment, reduce production costs.

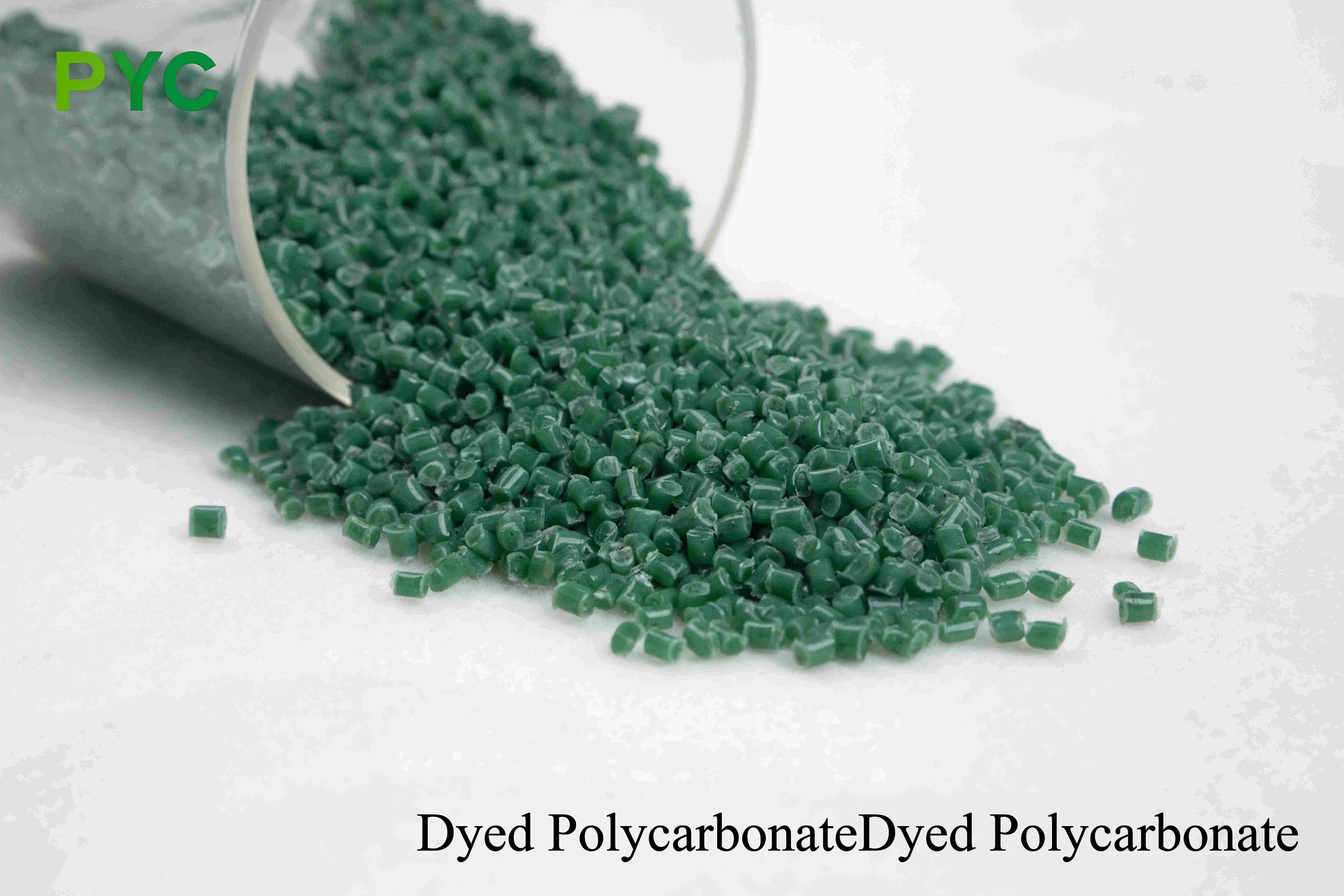

Stable color performance: RMABS color uniformity, suitable for dyeing and surface coating, to meet the appearance needs of different products.

Excellent chemical resistance: It has good resistance to acid, alkali, grease and other chemicals, and is suitable for electronic equipment shell, automotive interior and other applications.

Environmentally sustainable: Meet REACH and RoHS certification, reduce plastic waste emissions through recycling, and provide customers with high-quality, sustainable recycled ABS solutions.

Product Details Description

RMABS (Recycled Modified ABS) is an engineering plastic with high strength, excellent processability and environmental protection. The material adopts selected recycled ABS, optimized mechanical properties through advanced modification technology, so that it has high rigidity while ensuring good toughness, and can be widely used in automotive parts, home appliance shell, electronic products and office equipment and other fields.

RMABS has excellent impact resistance, can resist external impact and is not easy to break, especially suitable for products with high durability requirements. In addition, its fluidity is good, suitable for injection molding, extrusion, thermoforming and other processing processes, compatible with the original ABS production process, reducing production costs while ensuring stable product quality.

RMABS also has excellent chemical resistance, can resist acid, alkali and grease erosion, suitable for industrial equipment and electrical enclosures that need corrosion resistance. The products comply with REACH and RoHS certification to ensure environmental compliance and provide customers with high-quality and sustainable recycled ABS solutions.