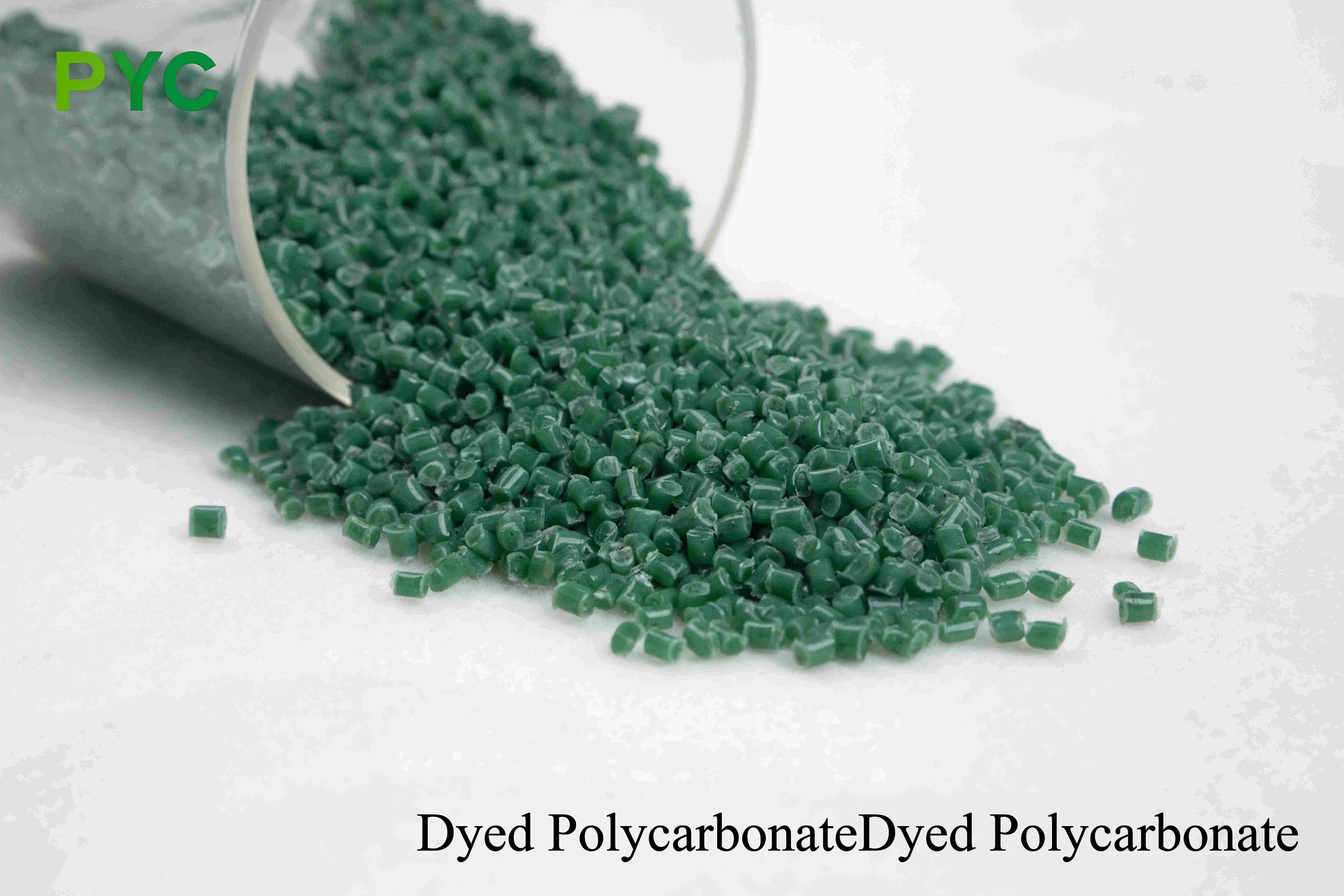

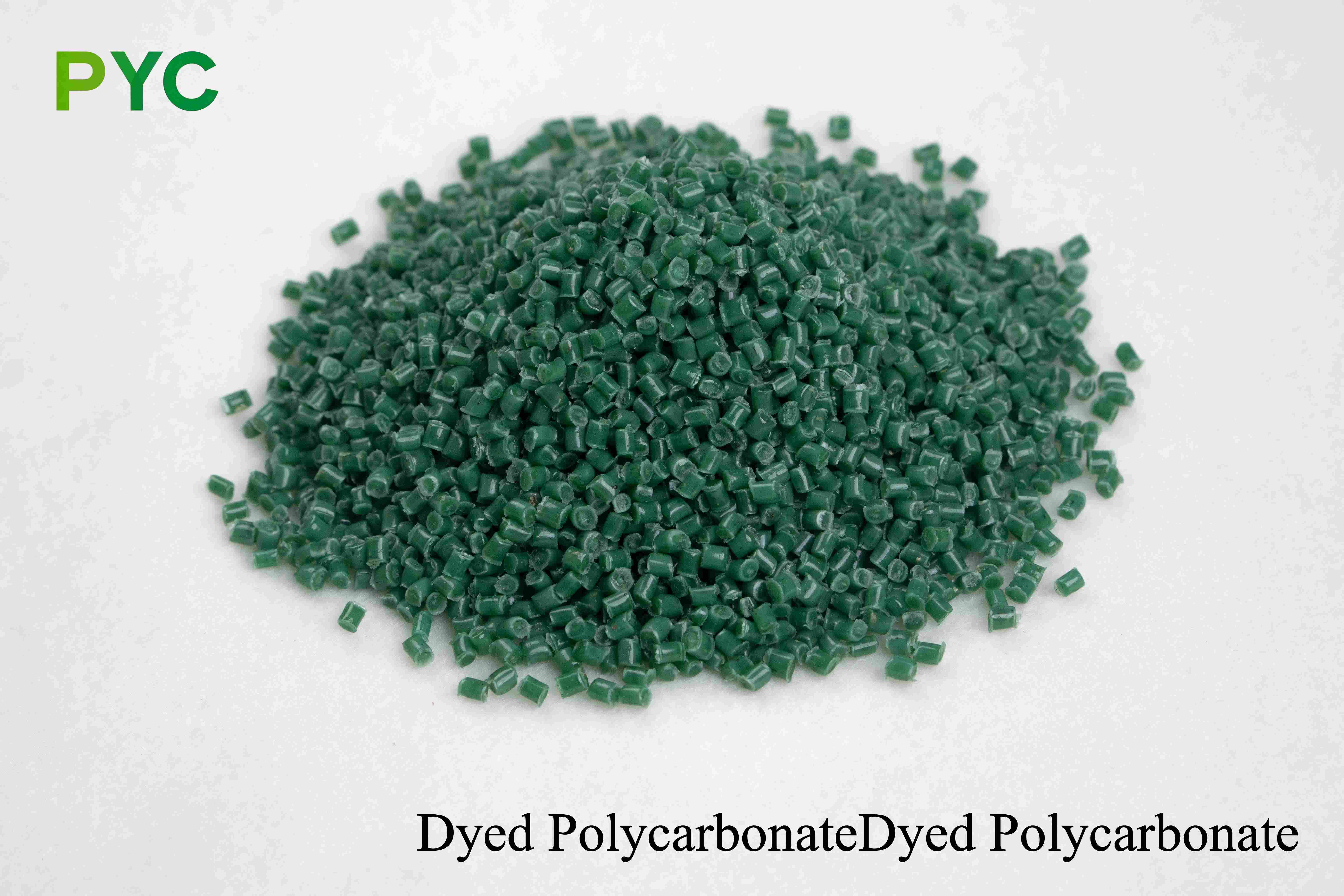

Dyed Polycarbonate

Product highlights

High quality ingredients

Dyed Polycarbonate is obtained from selected recovered polycarbonate materials from a single source and carefully selected by upstream manufacturers to ensure its purity and stability. Sources of recovered materials include:

Electronic product shell: including mobile phone shell, computer shell, etc., to ensure the high strength and transparency of recycled materials, suitable for high-performance electronic products.

Optical lenses: including optical lenses, eyeglass lenses, etc., recycled polycarbonate ensures its excellent optical performance and transparency to meet the needs of optical products.

Auto parts: including Windows, car shells, etc., recycled polycarbonate maintains high temperature resistance and impact resistance, which is suitable for the high requirements of the automotive industry.

The material retains its excellent mechanical strength, high temperature resistance and transparency during the production process, ensuring the final product's outstanding performance in color brightness and physical properties for a variety of high-end applications.

Strict quality control

Dyed Polycarbonate has undergone strict quality inspection during the production process to ensure that the color of each batch of products is uniform and not easily faded. All products are in compliance with REACH and RoHS environmental standards to ensure no emission of harmful substances and meet the requirements of sustainable development. In addition, the products have also passed a number of tests such as weather resistance and chemical corrosion resistance to ensure long-term stability in harsh environments, and are widely used in many fields such as electronics, automobiles, and construction.

Excellent color stability and brightness

Dyed Polycarbonate using high quality dyeing process to ensure bright and long-lasting color. The color of the material remains stable even under strong ultraviolet irradiation and is not easily faded after prolonged use. This property makes it excellent in applications such as advertising signage and lighting equipment that require bright and long-lasting colors.

Excellent impact resistance and durability

Dyed Polycarbonate has very high impact resistance, much higher than common plastic materials. Dyed Polycarbonate is still able to maintain its structural integrity in situations of high impact and impact, and is widely used in demanding fields such as automotive parts, electronic casings, protective equipment, etc., to ensure long-term safety of products.

Excellent transparency and optical properties

Dyed Polycarbonate has retained its excellent transparency and optical properties while dyeing, providing a clear visual effect. This property makes it ideal for lighting, optical lenses, display casings, etc., with both aesthetics and functionality.

Environmental protection and recyclability

Dyed Polycarbonate uses environmentally friendly dyes that meet global environmental standards and have a lower carbon footprint. Its own good recyclability, the product can be recycled after the end of the life cycle, in line with the concept of sustainable development and promote green production.

Presentation of Dyed Polycarbonate products

Dyed Polycarbonate is a high performance, brightly colored material with excellent physical properties, which is widely used in product designs requiring durability, aesthetics and high transparency. The material is dyed using an advanced dyeing process, which ensures that its color remains bright and stable during its long use. Dyed Polycarbonate provides excellent color effect and long-lasting performance, whether in outdoor advertising signs, lamp housings or automotive parts.

In terms of impact resistance, Dyed Polycarbonate is extremely impact-resistant, its impact strength is several times higher than that of ordinary plastic. In the face of high strength collision or drop, the material will not be easily broken or damaged, ensuring the safety of use under high load and high impact environment. This feature makes Dyed Polycarbonate the preferred material for many electronic product shells, car window glass, aviation equipment and other fields.

Although Dyed Polycarbonate has excellent impact resistance, Dyed Polycarbonate can still maintain relatively high transparency. Its excellent optical properties make it useful in applications requiring transparent or translucent materials. It is widely used in optical lenses, display shells, etc., meeting both aesthetic and functional requirements.

Furthermore, Dyed Polycarbonate is made of environmentally friendly dyes and raw materials, which comply with global environmental standards and has good recyclability. At the end of the life cycle of the product, it can be recycled and reused, reducing the waste of resources and in line with the trend of green production. The material not only performs superior in use, but is also environmentally friendly throughout its life cycle, promoting the concept of sustainable development.

With its excellent performance, good processability as well as environmental properties, Dyed Polycarbonate has demonstrated its strong competitiveness in a number of sectors. Dyed Polycarbonate provides ideal solutions to meet the market demand for high quality and environmentally friendly products, both in product designs requiring high strength, transparency and UV resistance.