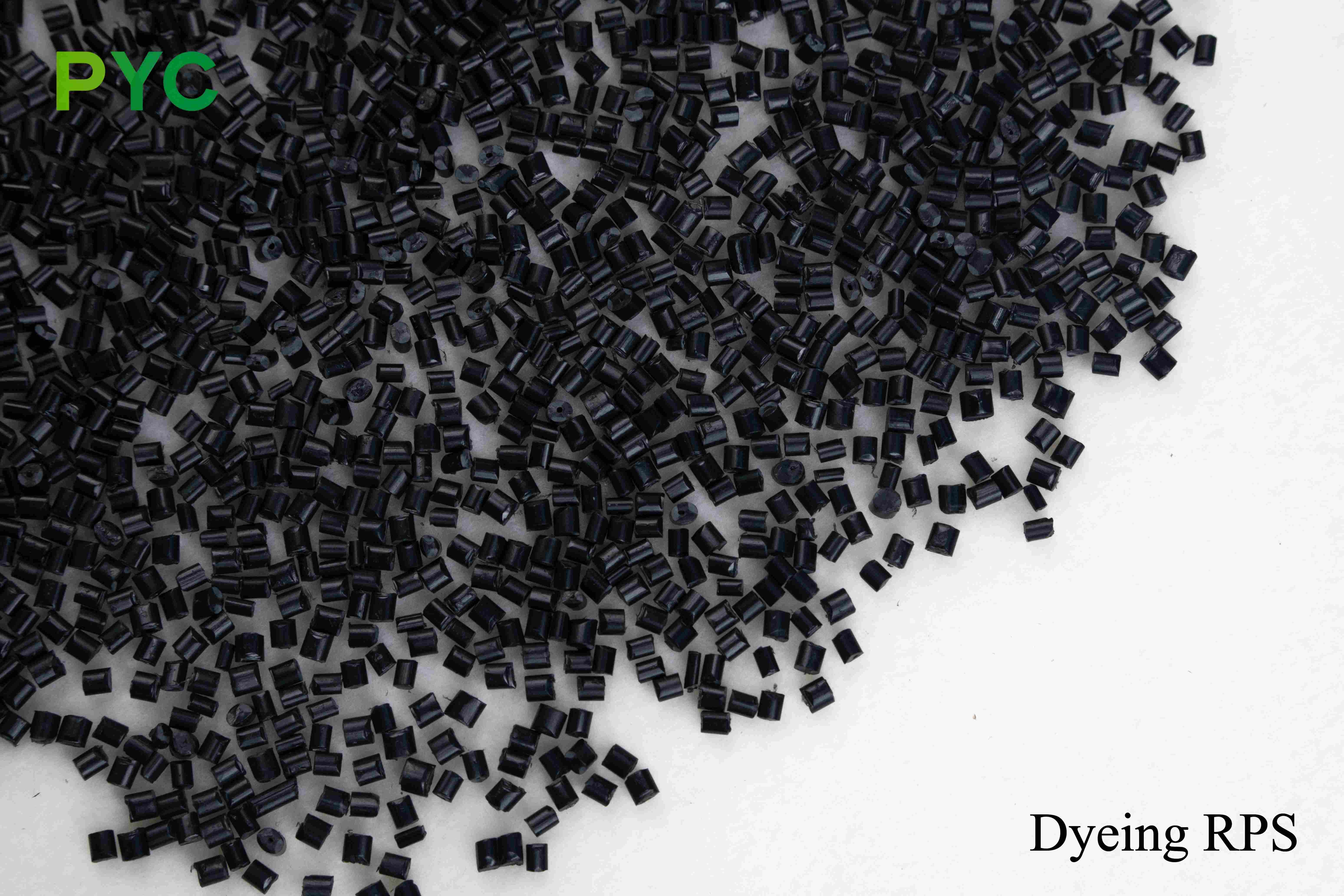

Dyeing RPS

Dyeing RPS product highlights

High quality ingredients

Dyeing RPS (dyed recycled polyphenylene sulfide) uses selected recycled RPS raw materials from a single source and are rigorously screened to ensure the purity and consistency of the material. Recycled sources include:

Electronic equipment shell: including electronic product shell, computer parts, etc., after fine screening of recycled polyphenylene sulfide, to ensure the high transparency of the material and excellent physical properties to meet the needs of high-end electronic products.

Automotive parts: including automotive interior parts, instrument panel parts, etc., the recovered polyphenylene sulfide material has been strictly screened to ensure its high temperature resistance, impact resistance and color uniformity.

Optical applications: including optical lenses, mirrors, etc., the recycled materials have been strictly screened and purified to ensure its excellent optical properties and high transparency.

The material goes through a fine dyeing process to ensure uniform and long-lasting color, which is suitable for a variety of high-end application scenarios and meets the requirements of precision processing and long-term use.

Strict quality control

Dyeing RPS undergo strict quality control in the production process to ensure color consistency and mechanical stability of each batch. All products are tested for weather resistance and chemical resistance to ensure excellent performance in different environments. Meet REACH and RoHS environmental protection certification to ensure that products comply with environmental regulations, widely used in electronic equipment enclosures, automotive parts and other fields.

Excellent dyeing uniformity

Dyeing RPS uses an advanced dyeing process to ensure an even distribution of dye throughout the material for a full, long-lasting color. Compared to traditional Dyeing materials, Dyeing RPS has a more stable effect, keeping the color consistent even after prolonged use, and is suitable for products that require even and durable color, such as packaging materials, decorations, etc.

Excellent weather resistance and UV resistance

Dyeing RPS have excellent weather resistance and UV resistance and are effective against damage to the material by UV rays in sunlight. After prolonged exposure to sunlight, Dyeing RPS retains its color bright and does not fade easily, making it ideal for applications in outdoor environments such as billboards, outdoor furniture, etc.

Environmentally friendly and recyclable

Dyeing RPS uses an environmentally friendly dye that meets modern environmental standards, and the polystyrene itself is well recyclable. At the end of the product's life cycle, Dyeing RPS can be recycled, reducing waste of resources and helping to promote green production and a circular economy.

High strength and good workability

With high strength and hardness, Dyeing RPS are able to withstand greater external forces and pressures without deformation or damage. In addition, it is machinable and can be easily formed by injection molding, etc., making it suitable for a wide range of complex shapes and fine processes.

Dyeing RPS product introduction

Dyeing RPS (dyed polystyrene) is a high performance plastic material using an advanced dyeing process, widely used in packaging, home decoration, advertising signs and other fields. The material not only has excellent color performance, but also excellent weather resistance, UV resistance, and environmental protection properties, enabling it to maintain outstanding performance in a variety of applications.

The Dyeing process of Dyeing RPS ensures uniformity and persistence of color. Compared to traditional polystyrene, Dyeing RPS is fuller in colour and effectively resists UV erosion and the fading problems caused by sun exposure. Even if used in the outdoor environment for a long time, the color of the material can remain bright, and it is widely used in advertising signs, signage, outdoor furniture and other fields that need to be displayed for a long time.

In addition, Dyeing RPS has high strength and hardness, is able to cope with a variety of physical shocks and loads, and is suitable for making industrial supplies, packaging containers, etc., which require high strength. Its good processability makes it can be molded by common injection molding, extrusion and other processing processes, adapt to complex shape and detail requirements, and can meet the needs of diverse product design.

In terms of environmental protection, Dyeing RPS uses environmentally friendly dyes and raw materials, which meet international environmental standards. Its recyclability allows the product to be effectively recycled at the end of its useful life cycle, promoting circular economy and sustainable development.

In summary, Dyeing RPS is an ideal choice in multiple industries due to its excellent dyeing effect, weather resistance, environmental protection and high strength. Whether used in outdoor advertising, everyday items or industrial products, this material offers a high-quality solution that meets the combined consumer needs for performance, environmental protection and aesthetics.