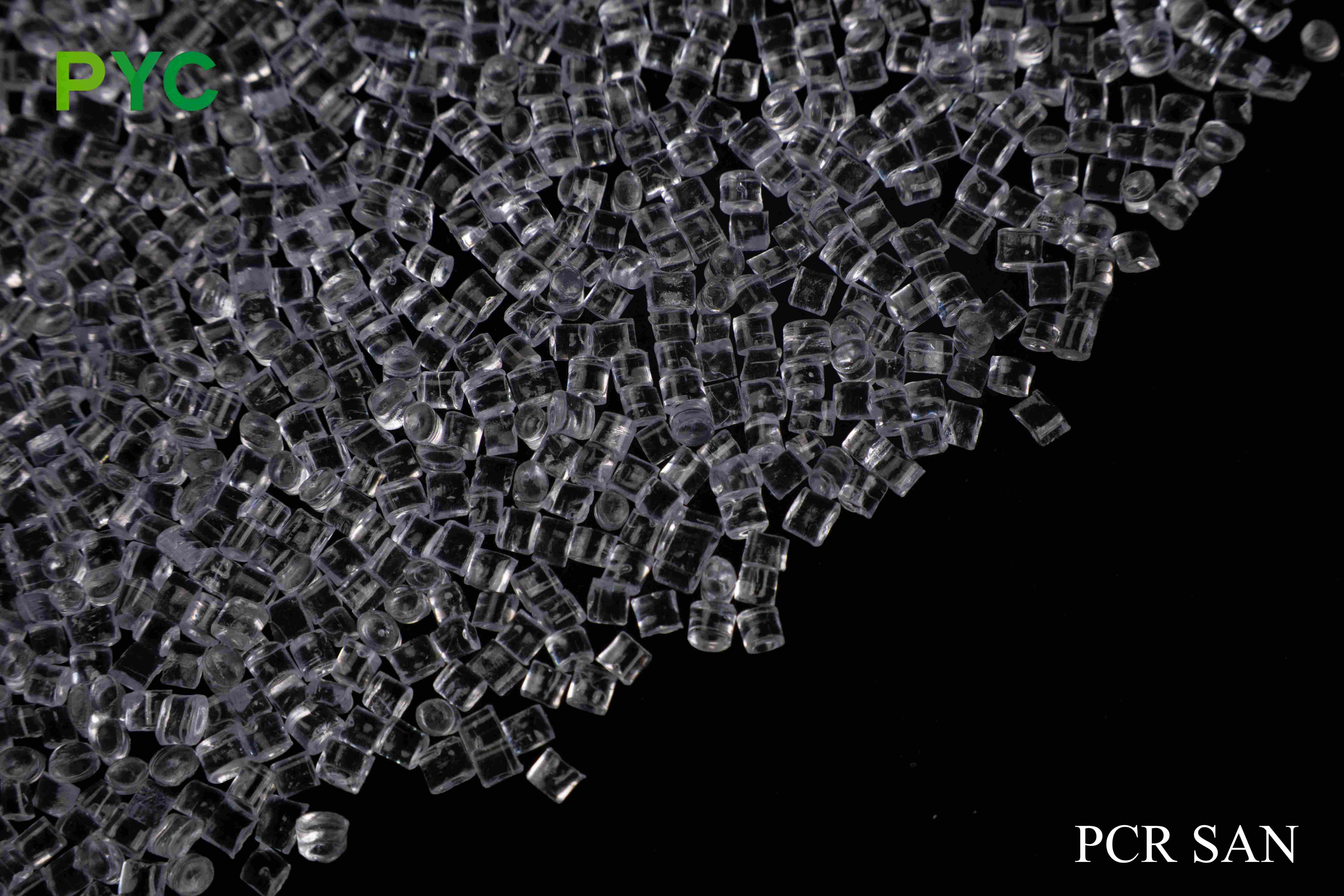

PIR SAN

PIR SAN (PostIndustrial Recycled StyreneAcrylonitrile) - Post-industrial recycled styreneacrylonitrile copolymer

PIR SAN is an environmentally friendly plastic made by recycling styreneacrylonitrile copolymer (SAN) waste from industrial production processes. Styryl acrylonitrile copolymer (SAN) is an engineering plastic with excellent transparency, rigidity and chemical resistance, widely used in electronics, home appliances, automotive as well as packaging industries. By recycling SAN waste, PIR SAN not only reduces resource waste, but also promotes circular economy and green production.

Product Details

1. High-quality recycled feedstock sources

PIR SAN's recycled feedstock is primarily derived from waste styrene acrylonitrile copolymer materials generated from industrial production, including:

Production waste: e.g. injection molded parts, trimmings, extruded materials, etc.

Waste plastic products: such as waste SAN packaging containers, electrical appliance housings, etc.

Industrial product waste: such as discarded instrument shells, home appliance shells, automobile parts, etc.

These wastes are carefully screened, cleaned and processed to transform them into high-quality PIR SAN raw materials, ensuring the stability and excellent performance of the final product.

2. Strict quality control

PIR SAN conducts strict quality control during the manufacturing process. Each batch of recycled material undergoes a number of tests such as tensile strength, impact resistance, transparency, hardness, etc. to ensure that the final product is stable and meets industry standards. Quality control allows PIR SAN to be used consistently in a variety of applications and to meet the performance needs of a wide range of products.

3. Excellent performance

High transparency: PIR SAN has very good transparency and can be used as a substitute for glass in products such as transparent packaging containers and housings.

Good rigidity: PIR SAN has a high degree of rigidity and strength, making it suitable for applications subject to high mechanical stress.

Chemical resistance: PIR SAN has good resistance to many chemicals, solvents and oils and has a wide range of applications in the chemical and packaging sectors.

Heat resistance: PIR SAN has good heat resistance, can maintain stable physical properties within a certain temperature range, suitable for some high temperature working environment.

Excellent processing performance: PIR SAN can be molded by injection molding, extrusion, and other processing methods, adapting to various production processes.

4. Environmental protection and sustainability

PIR SAN is a recycled material that reduces the need for new raw materials and effectively lowers plastic waste emissions, in line with environmental and sustainability goals. By recycling SAN waste, PIR SAN reduces the carbon footprint of the production process and helps companies reduce production costs and go green.

5. Cost-effectiveness

By using PIR SAN as a raw material, companies can reduce their production costs. Recycling waste materials not only saves on raw material costs, but also reduces energy consumption in production. PIR SAN also helps companies to increase their competitiveness in the market through green production methods.

Application area

Packaging industry: PIR SAN has high transparency and good rigidity, and is often used in the manufacture of transparent packaging containers, food packaging boxes, cosmetic bottles, etc., which has a strong market demand.

Home appliance industry: PIR SAN is widely used in the housing of home appliance products such as TV sets, refrigerators, air conditioners, providing excellent rigidity and chemical resistance.

Automotive industry: PIR SAN is widely used in automotive components, such as dashboards, headlight housings, door handles, etc., to provide stable physical properties and beautiful appearance.

Electronic products: PIR SAN can be used to manufacture mobile phone casings, computer casings, electrical accessories, etc., with excellent processability and chemical resistance.

Medical devices: PIR SAN can also be used for medical equipment housings, instrument housings, etc., providing high transparency and mechanical strength to ensure product reliability and service life.

Product Advantages

High transparency: PIR SAN provides a clear and transparent appearance, suitable for transparent packaging and display needs, ensuring a beautiful appearance of the product.

Good rigidity and strength: PIR SAN performs well when subjected to mechanical loads and is suitable for industrial products that require high rigidity and strength.

Excellent chemical resistance: PIR SAN has a strong resistance to a variety of chemicals, suitable for use in chemical packaging and corrosion resistant parts.

Heat resistance: PIR SAN maintains good physical properties within a certain temperature range and is suitable for applications in high temperature environments.

Environmental protection: PIR SAN is made of recycled SAN waste, which helps reduce waste accumulation and dependence on new resources, and meets the environmental protection requirements of sustainable development.

Production and technical advantages

Advanced recycling process: Through advanced recycling technology, PIR SAN ensures that the performance of recycled materials is similar to that of new materials, meeting the needs of high-performance products.

Strong processing adaptability: PIR SAN can be produced by various processing processes such as injection molding and extrusion, and is suitable for the manufacture of various forms of products.

Good processing performance: PIR SAN has good fluidity and formability, which can realize accurate mold forming and ensure high quality product production.