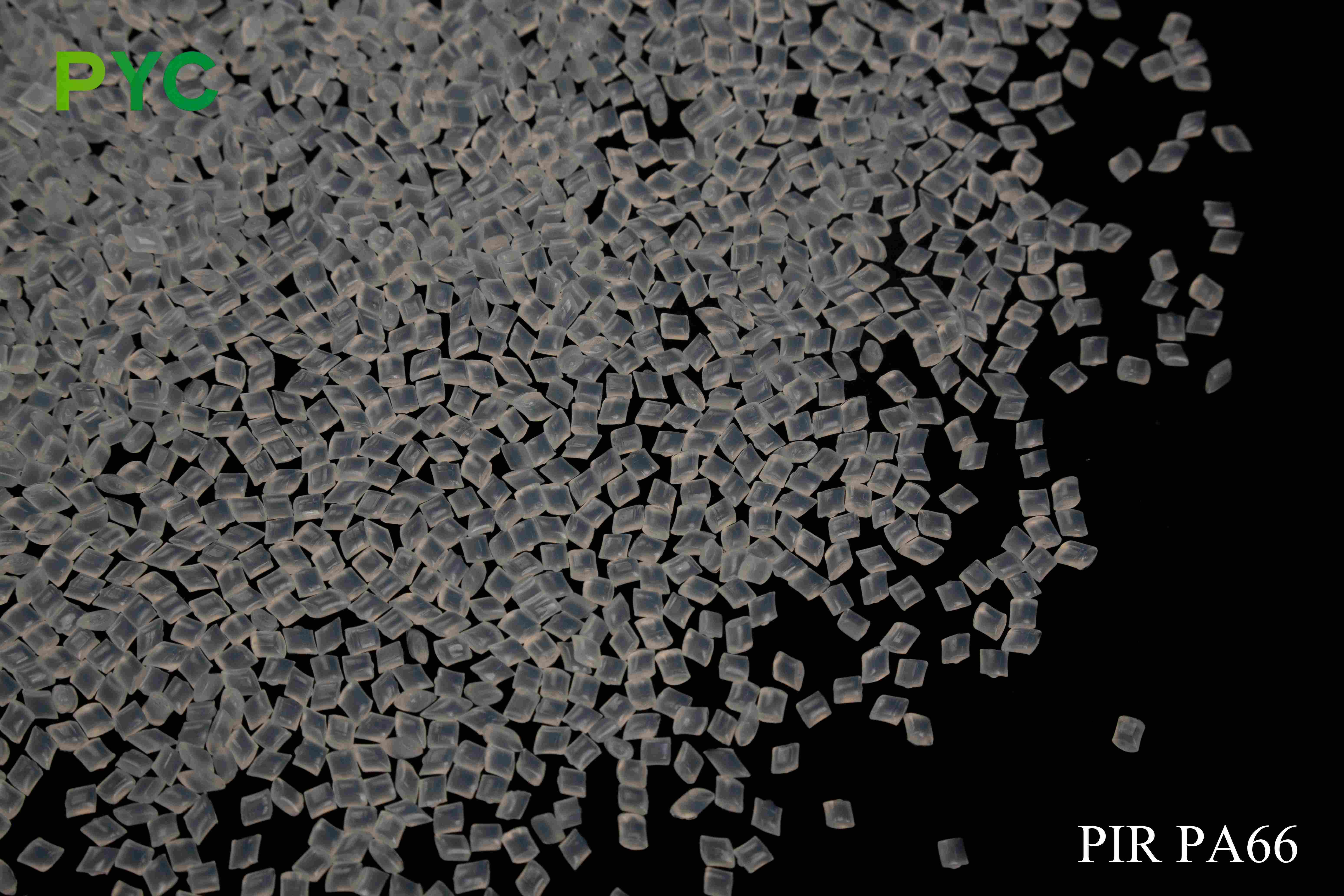

PIR PA66

PIR PA66 (PostIndustrial Recycled Polyamide 66) - Post-industrial recycled polyamide 66

PIR PA66 is an environmentally friendly plastic made by recycling polyamide 66 (PA66) waste from the industrial production process. As a high-performance engineering plastic, PA66 has excellent mechanical strength, wear resistance, heat resistance and chemical stability, so it has been widely used in automotive, electronics, electrical, machinery and other fields. By recycling discarded PA66 raw materials, PIR PA66 not only reduces production costs, but also helps reduce the accumulation of plastic waste, in line with the global Sustainable Development Goals.

Product Details

1. High-quality recycled feedstock sources

The recycled raw materials for PIR PA66 are mainly derived from waste polyamide 66 materials from industrial production, including:

Production waste: e.g. injection molded parts, fiber waste, trimmings, etc.

Waste plastic products: e.g. waste PA66 parts, electronic housings, automobile parts, etc.

Textile industry waste: such as waste nylon 66 fibers, fabrics and so on.

These waste materials are finely screened, cleaned and processed to transform them into high-quality PIR PA66 raw materials, ensuring stability and high performance in the final product.

2. Strict quality control

PIR PA66 is strictly quality controlled during the production process. Each batch of material is tested for a number of indicators, including mechanical properties, tensile strength, impact toughness, water absorption, etc., to ensure that the product has a stable and reliable performance in real-world applications. Through sophisticated recycling and processing techniques, we ensure that each production step meets industry standards.

3. Excellent performance

High mechanical strength: PIR PA66 has very high tensile and compressive strength, suitable for high load, high stress environment, such as automotive parts, machinery and equipment.

Abrasion resistance: PIR PA66 has excellent abrasion resistance and is suitable for use in gears, bearings, mechanical parts, and other applications where high abrasion resistance is required.

Heat Resistance: PIR PA66 has excellent thermal stability and is able to maintain its performance in high temperature environments, making it suitable for applications in high temperature working conditions.

Chemical Resistance: PIR PA66 is highly resistant to a wide range of chemicals, oils and solvents, making it suitable for use in harsh chemical environments.

4. Environmental protection and sustainability

PIR PA66 is a recycled material that reduces the need for raw materials, effectively reduces plastic waste emissions, and lowers energy consumption and carbon emissions in the manufacturing process.PIR PA66 not only helps the environment, but also promotes a green economy and meets the global demand for sustainable development.

5. Cost-effectiveness

The use of PIR PA66 as a raw material has cost advantages over conventional new materials. By recycling production waste, we not only save on raw material procurement costs, but also reduce energy consumption in production, which helps to increase the competitiveness of our company.

Application area

Automotive industry: PIR PA66 is widely used in automotive parts, engine parts, shell and interior parts, etc., suitable for parts requiring high strength, high temperature resistance and impact resistance.

Electronic industry: In electronic products, PIR PA66 is used as shell, connector, plug, etc., with good electrical insulation performance and corrosion resistance.

Machinery industry: Suitable for the manufacture of various mechanical parts, such as gears, pulleys, bearings, etc., PIR PA66's wear resistance makes it an ideal choice.

Electrical industry: PIR PA66 is used in electrical equipment enclosures, electrical accessories, etc., with good heat resistance and electrical performance.

Product Advantages

High mechanical strength: PIR PA66 offers excellent tensile and compressive strength for high strength and high impact applications.

High heat resistance: PIR PA66 can withstand high operating temperatures and is widely used in parts in high temperature environments.

Wear resistance: The wear resistance of PIR PA66 is very good, suitable for use in products that require long-term wear resistance, such as gears and bearings.

Environmental protection: PIR PA66 is made from recycled PA66 material, which meets environmental requirements and helps reduce the impact of plastic waste on the environment.

Cost-effectiveness: PIR PA66 reduces production costs by recycling materials and helps enterprises improve the market competitiveness of their products.

Production and technical advantages

Advanced recycling process: The production of PIR PA66 adopts modern recycling technology to ensure that the quality and performance of the material are close to the new material and meet the high standard requirements of industrial applications.

Strong processing adaptability: PIR PA66 can be processed by injection molding, extrusion and other ways, suitable for a variety of different types of product production.

Good processing performance: PIR PA66 has good fluidity in the processing process, which is suitable for high-precision mold production and can ensure accurate product manufacturing.