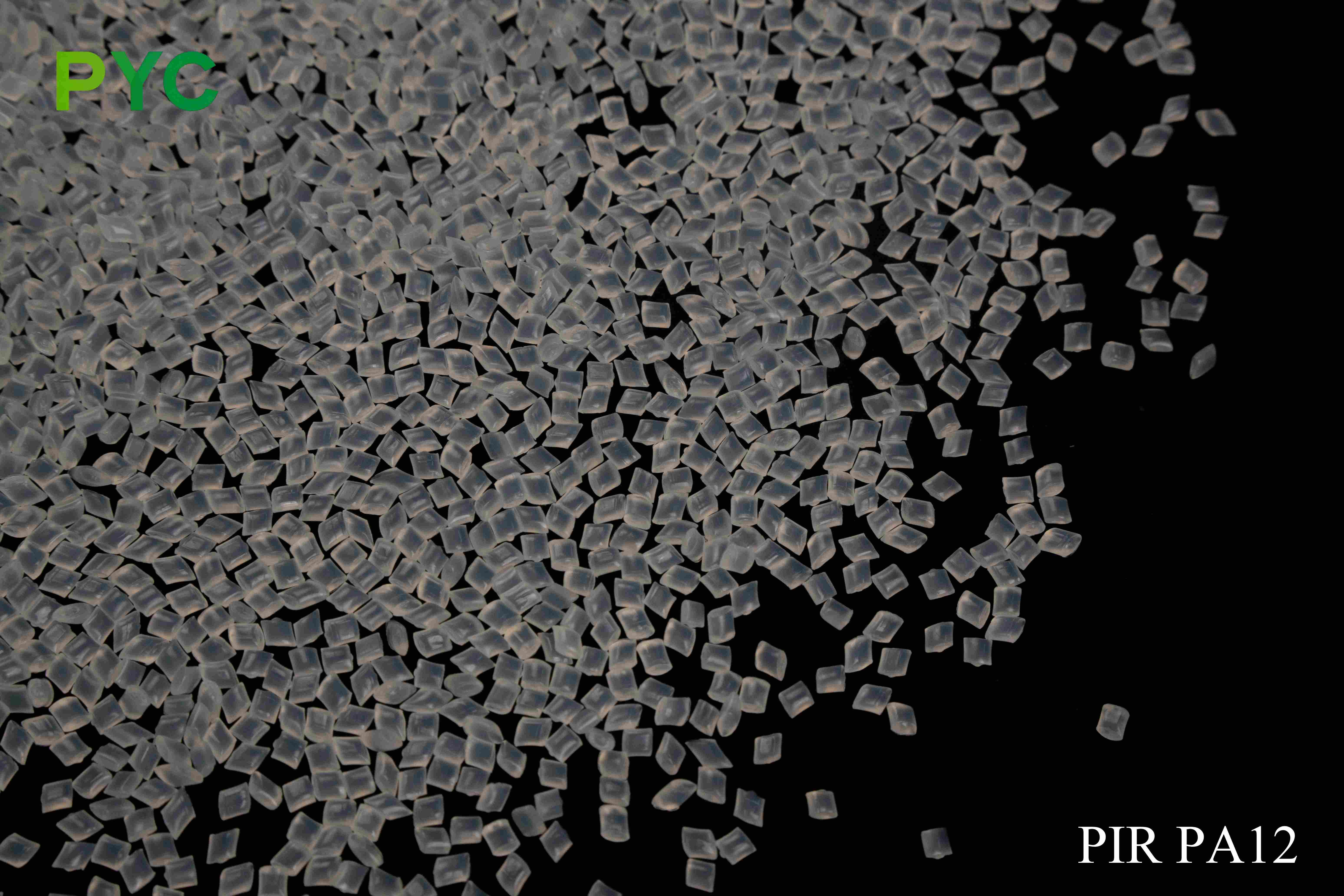

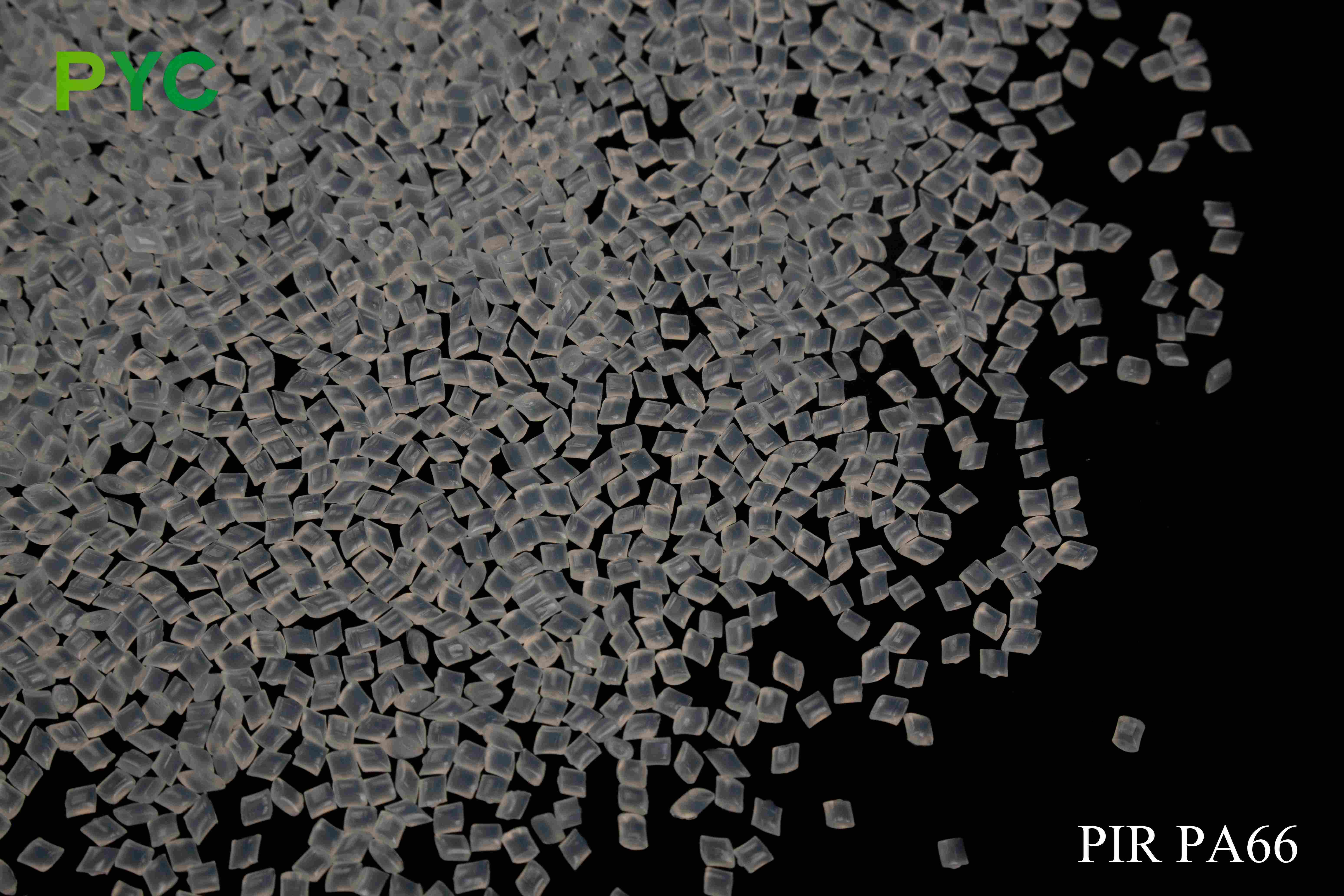

PIR PA12

PIR PA12 (PostIndustrial Recycled Polyamide 12) - Post-industrial Recycled polyamide 12

PIR PA12 is an environmentally friendly plastic produced by recycling industrial waste polyamide 12 (PA12) material. With excellent chemical resistance, low water absorption and excellent flexibility, polyamide 12 is widely used in high-end manufacturing fields such as automotive, electronics and aviation. PIR PA12 reduces the need for raw petroleum resources by recycling waste generated during the production process, while also helping to reduce the accumulation of plastic waste, in line with sustainable production models.

Product Details

1. High-quality recycled feedstock sources

The recycled raw materials for PIR PA12 are mainly derived from waste polyamide 12 materials from industrial production, including:

Production waste: e.g. polyamide 12 injection-molded parts, trimmings and residues.

Waste plastic products: e.g. waste PA12 shells, automobile parts, etc.

Recycled fibers: e.g. used nylon 12 fibers and technical textiles.

These recycled materials are rigorously screened, cleaned, pulverized and reprocessed to form high-quality PIR PA12 raw materials, ensuring consistent performance and environmental compliance.

2. Strict quality control

During the manufacturing process, PIR PA12 undergoes strict quality control to ensure that its performance meets industry standards by testing a number of indicators, including tensile strength, impact toughness, water absorption, and thermal stability. Each batch of recycled material is finely processed to ensure high consistency and excellent performance of the final product.

3. Excellent performance

Low Water Absorption: PIR PA12 has an extremely low water absorption rate, which allows it to maintain stable dimensions and performance in wet environments, especially for the aerospace and automotive industries.

Chemical Resistance: PIR PA12 has excellent resistance to many chemicals, solvents and oils, making it suitable for applications in highly corrosive environments.

Flexibility: PA12 maintains good flexibility, even at low temperatures, and is suitable for use in elastic parts.

Thermal stability: PIR PA12 maintains its properties at higher temperatures and is suitable for use in high temperature environments.

Excellent Mechanical Properties: PIR PA12 has high tensile strength and impact resistance, making it suitable for high load and high impact applications.

4. Environmental protection and sustainability

PIR PA12 is produced from recycled materials, reducing the need for new raw materials and helping to reduce the environmental burden of plastic waste. The recycling process reduces energy consumption and carbon emissions, making it an ideal material to drive a green economy and sustainable development.

5. Cost-effectiveness

Because PIR PA12 is produced from recycled materials, it has a cost advantage over traditional raw materials, helping to reduce production costs for companies. At the same time, PIR PA12 maintains its excellent properties, allowing companies to produce high quality products while saving money.

Application area

Automotive industry: PIR PA12 is widely used in automotive parts, fuel pipelines, sensor shells, etc., especially suitable for high temperature, highly corrosive environment, and can work stably in harsh automotive engine room environment for a long time.

Aerospace: In the aerospace sector, PIR PA12 is used to manufacture lightweight, high-temperature resistant components with very low water absorption, suitable for use in the manufacture of aircraft and aviation equipment.

Electronics industry: Widely used in components such as housings and connectors for electronic devices, the corrosion resistance and thermal stability of PA12 enable it to remain stable in high temperatures and harsh environments.

Oil and gas industry: Due to its excellent oil and chemical resistance, PIR PA12 is used in the oil and gas industry to manufacture pipes, conveyor belts, seals and other components.

Product Advantages

Low water absorption: PIR PA12 has an extremely low water absorption rate, avoiding performance problems caused by water absorption and expansion in humid environments.

Strong chemical resistance: PIR PA12 is resistant to a variety of solvents, oils and chemicals, making it suitable for applications in chemical environments.

Flexibility: Even at low temperatures, PIR PA12 still exhibits good flexibility and is suitable for applications that require high elasticity.

Good thermal stability: PIR PA12 can maintain its stable performance at higher temperatures and is suitable for high temperature environments.

Environmental protection: PIR PA12 is produced by recycling waste PA12 materials, which meets the requirements of environmental protection and sustainable development, and helps to reduce plastic waste.

Production and technical advantages

Advanced recycling process: PIR PA12 adopts modern recycling technology to ensure the quality and performance of recycled materials, close to new materials, and meet the needs of high-end industrial applications.

Strong processing adaptability: PIR PA12 can be molded by injection molding, extrusion and other processing methods to adapt to different types of product manufacturing needs.

Excellent processing performance: PIR PA12 has good fluidity in the processing process, which is suitable for precision mold production and can ensure the manufacturing of high-precision products.