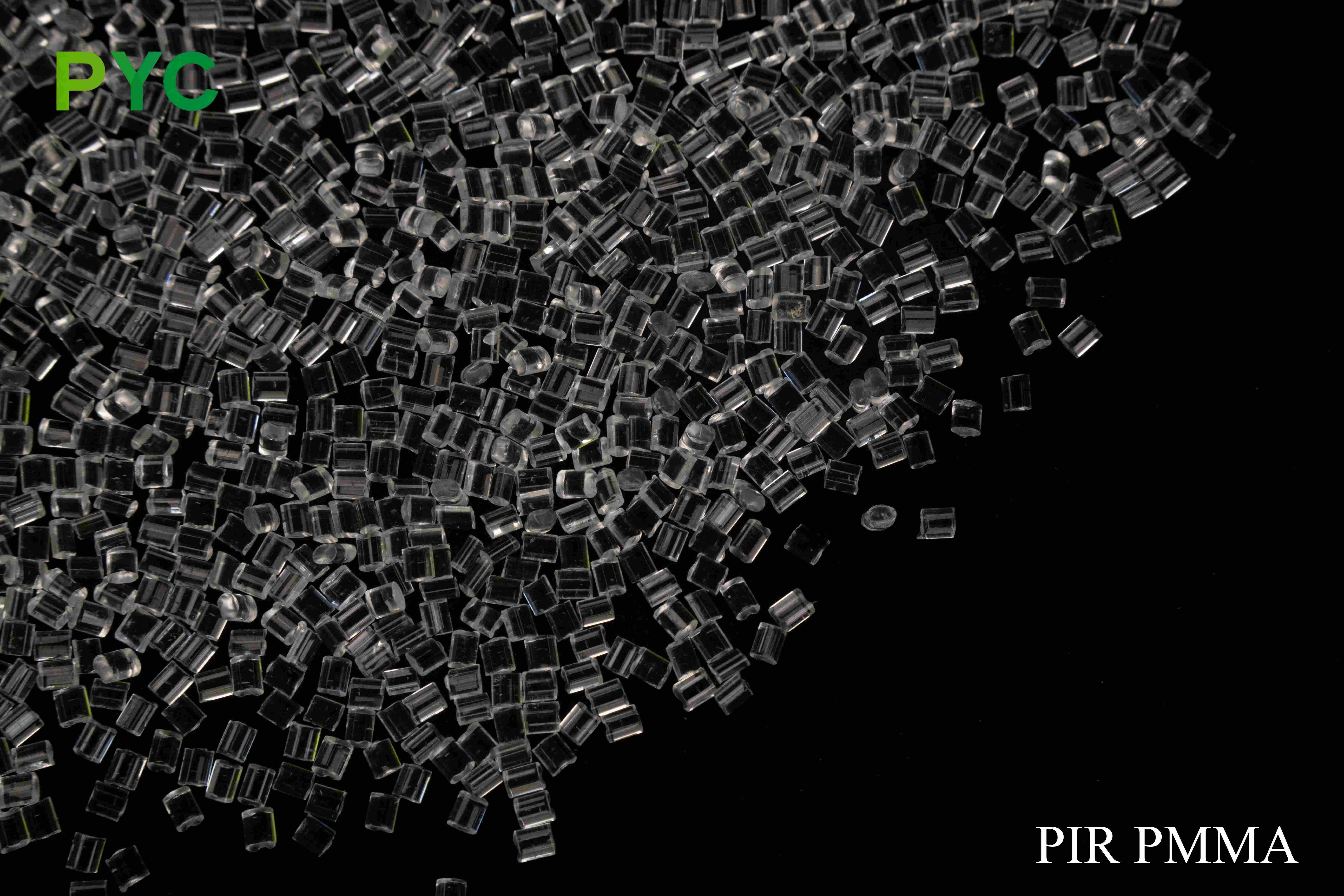

PIR PMMA

PIR PMMA (PostIndustrial Recycled Polymethyl Methacrylate) - Post-industrial recycled polymethyl methacrylate

PIR PMMA is a high-performance plastic made by recycling industrial waste polymethyl methacrylate (PMMA) material and reprocessing it. PMMA, also known as acrylic or plexiglass, has excellent transparency, weather resistance and UV resistance. PIR PMMA recycles the waste produced in the production process, such as acrylic sheet scraps and discarded acrylic products, and re-uses these waste materials to make high-quality recycled materials, which are widely used in optics, construction, automobiles, electronics and other fields.

Product Details

1. High-quality recycled feedstock sources

The recycled raw materials for PIR PMMA are mainly from waste materials from industrial production, such as:

Production trimmings: including acrylic sheets, products in the production process of waste trimmings.

Discarded acrylic products: such as discarded billboards, light boxes, display racks and so on.

Waste optical products: such as discarded optical lenses, display panels, etc.

These waste materials are screened, cleaned and processed to transform them into high-quality PIR PMMA raw materials that guarantee transparency, mechanical properties and environmental benefits.

2. Strict quality control

PIR PMMA undergoes strict quality control during the production process to ensure the stability and high quality of each batch of material. A number of performance tests, such as tensile strength, transparency, impact resistance, weatherability, etc., are passed to ensure its high performance in different applications.

3. Excellent performance

Excellent Transparency: PIR PMMA has a high transparency similar to that of newer materials, making it suitable for use in applications requiring a high degree of transparency, such as display cases, light boxes, billboards, etc.

UV and Weather Resistance: PIR PMMA has excellent UV resistance, even when exposed to sunlight outdoors for a long time, it will not turn yellow or brittle, and maintains its long-term aesthetic appearance.

High mechanical strength: PIR PMMA has high tensile strength and impact resistance, even under a certain degree of external force.

Excellent processing performance: PIR PMMA is easy to process and can be treated by cutting, laser engraving, polishing and other processes to meet the needs of a variety of complex designs and shapes.

4. Environmental protection and sustainability

PIR PMMA effectively reduces the accumulation of waste materials in the production process by recycling waste PMMA materials, which is in line with the requirements of environmental protection and sustainable development. The use of recycled materials reduces the need for new raw materials, lowers energy consumption and waste generation, and promotes the recycling of resources.

5. Cost-effectiveness

Because PIR PMMA is made from recycled material, its production costs are more competitive compared to newly produced PMMA. Lower raw material procurement costs in the recycling process make PIR PMMA a cost-effective plastic material and a solution for companies to reduce production costs.

Application area

Advertising and display industry: PIR PMMA is widely used in billboard, light box, display stand, sign plate and so on because of its excellent transparency and excellent processing performance.

Construction industry: Used for Windows, roof panels, fences and other building materials, with good weather resistance and transparency, can withstand the test of long-term exposure to the sun.

Automotive industry: Used for automotive lighting covers, dashboards, Windows, etc., to provide high transparency and impact resistance.

Electronics industry: such as display panels, electronic product housings, etc., PIR PMMA has excellent performance in visual effects and durability.

Product Advantages

High transparency: The transparency of PIR PMMA is almost the same as that of new materials and is suitable for applications with high transparency and decorative requirements.

Uv and weather resistance: PIR PMMA retains its transparency and strength even when used outdoors or in high UV environments for long periods of time.

High strength and impact resistance: With high impact resistance and mechanical strength, it is suitable for applications requiring long-term durability and resistance to external forces.

Environmental protection: Made by recycling waste PMMA material, in line with environmental requirements, help to reduce resource waste.

The recycling process reduces production costs, making PIR PMMA a cost-effective material that can provide businesses with a cost-efficient: saving solution.

Production and technical advantages

Advanced recycling technology: The use of advanced recycling processes and optimized processing technology ensures that the performance of PIR PMMA is comparable to that of new materials.

A wide range of processing adaptability: PIR PMMA can be processed through a variety of processes such as cutting, thermoforming, laser engraving, etc., to adapt to different application needs.