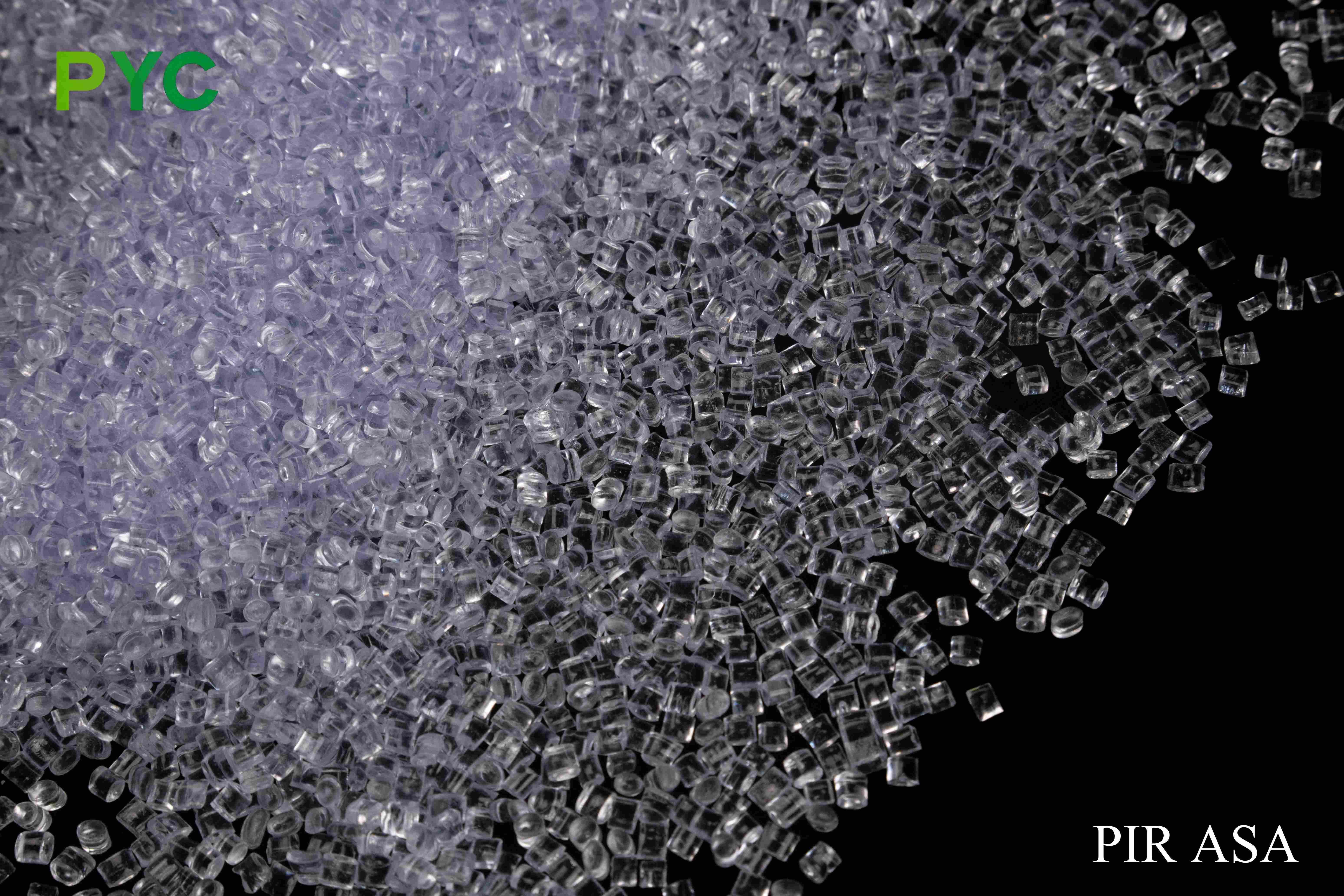

PIR ASA

PIR ASA (PostIndustrial Recycled Acrylonitrile Styrene Acrylate) - Post-industrial recycled acrylonitrile styrene acrylate copolymer

PIR ASA (Postindustrial recycled Acrylonitrile) is a high-performance plastic made from recycled industrial waste that combines the characteristics of acrylonitrile, Styrene and Acrylate with excellent mechanical properties, weather resistance and UV resistance. The recycled materials of PIR ASA come from the waste in the industrial production process, including the scraps and waste in the plastic production, which are converted into high-quality recycled materials after strict recycling and processing, and are widely used in automobile, construction, electronics and home appliances and other industries.

Product Details

1. Main sources of recovered raw materials

Waste from the production process

In the production process of ASA products, some waste materials are often generated, such as runner materials, edges and rejects. These wastes are unused and pure, and are an important source of high-quality industrially recycled ASA.

Recycling Source Example:

Runner material: the part of the runner produced during the injection molding process.

Edge: The edge waste generated in the process of product trimming.

Non-conforming products: inferior or defective products produced in production.

Waste from the plastics processing industry

In the plastics processing industry, the processing of ASA materials generates some wastes, such as extrusion wastes and trimming wastes. These wastes are recycled and can be used to produce high quality recycled ASA.

Recycling Source Example:

Extrusion Waste: Waste produced during the extrusion of ASA materials.

Edge-cutting waste: Waste generated in the process of edge-cutting of ASA products.

recovery process

The recycling process for high-quality industrial recycled ASA typically includes the following steps:

Collection and Sorting: ASA waste generated during industrial production is collected and sorted according to material and color.

Cleaning and pre-treatment: The recycled ASA waste is cleaned to remove surface dust and impurities.

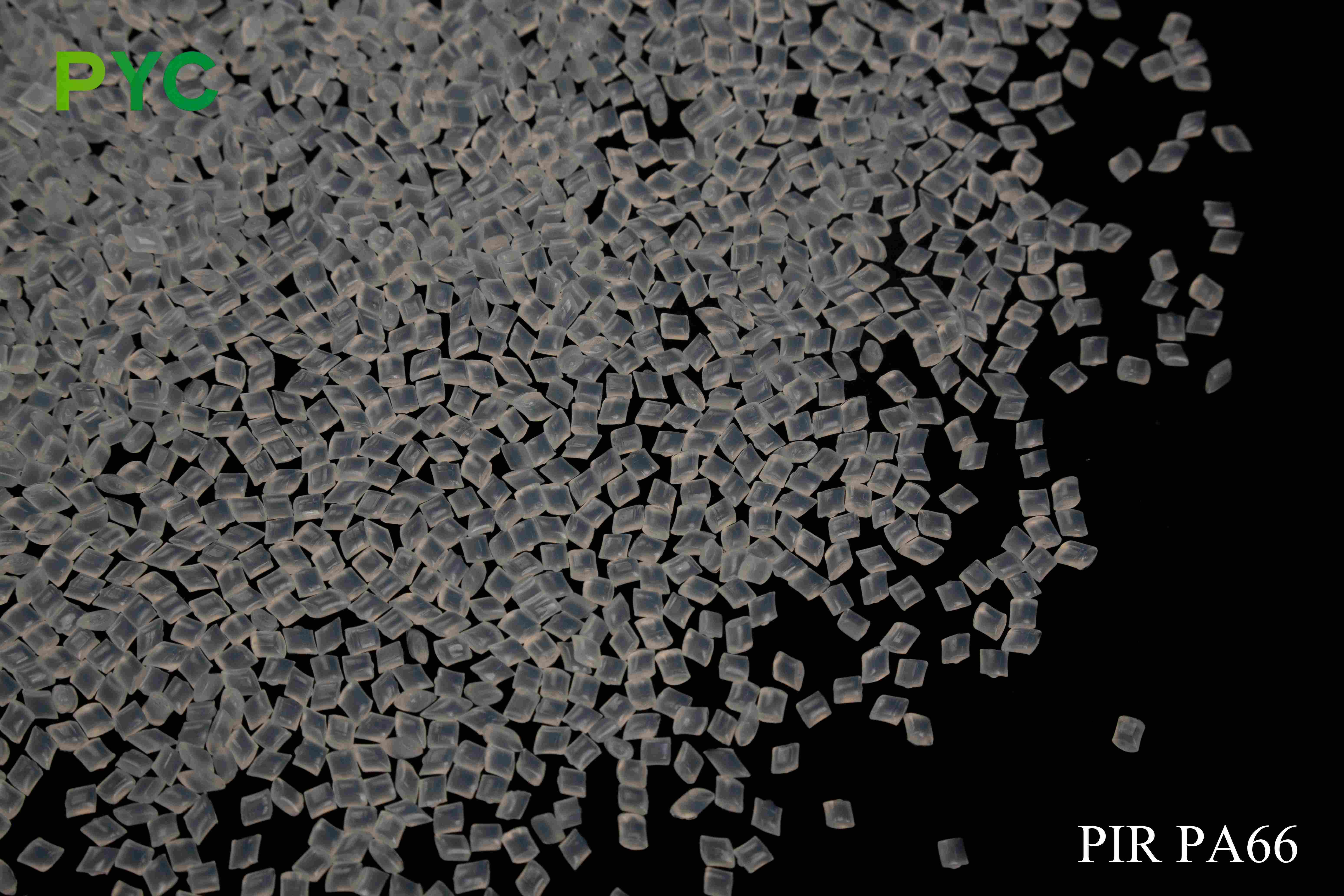

Crushing and melting: The cleaned ASA waste is crushed and subsequently processed into recycled pellets through a melting process.

Filtration and granulation: Filtering technology is used to remove tiny impurities from the molten ASA to ensure the purity of the recycled material, which is then granulated.

Quality testing: quality testing of recycled pellets to ensure that their performance meets the relevant standards and application requirements.

2. Strict quality control

PIR ASA adheres to strict quality control standards during the production process to ensure the reliability and stability of each batch of material. A number of performance tests, such as tensile strength, impact resistance, heat resistance, weather resistance, etc., ensure the reliability and high performance of PIR ASA products in different environments.

3. Excellent performance

Excellent Weather Resistance: PIR ASA has excellent UV resistance and will not fade or become brittle even after prolonged exposure to outdoor environments.

High mechanical strength: PIR ASA has high tensile strength and impact resistance, making it suitable for applications subject to high loads.

High Temperature and Chemical Resistance: PIR ASA is resistant to high temperatures and has good resistance to most chemicals for harsh working environments.

Excellent processability: PIR ASA has good processability, which can be processed by injection molding, extrusion and other processes to adapt to the production of different shapes and sizes.

4. Environmental protection and sustainability

PIR ASA is a material made by recycling industrial waste, effectively reducing the accumulation of waste and meeting the requirements of sustainable development and environmental protection. The use of recycled materials not only helps reduce the need for new raw materials, but also effectively reduces resource consumption and carbon emissions.

5. Cost-effectiveness

Since PIR ASA uses recycled materials, production costs are relatively low. The recycling process reduces the dependence on new materials, making the product more economical and helping companies to reduce production costs while meeting the market demand for environmentally friendly materials.

Application area

Automotive industry: PIR ASA can be used to produce automotive exterior trim parts, window frames, bumpers, instrument panels, etc., with good weather resistance, UV resistance and high strength.

Construction industry: In the field of construction, PIR ASA can be used for door and window frames, roofing materials, exterior wall decoration, etc., with strong corrosion resistance and high temperature resistance.

Home appliance industry: such as TV housings, refrigerator external parts, washing machine housings, etc., PIR ASA provides high strength, high temperature resistance performance to adapt to the harsh requirements of home appliance products.

Electronics industry: Used in the manufacture of electronic product housings, switch panels, etc., to ensure their stability and durability.

Product advantages

Excellent weather resistance and UV resistance: even in outdoor or high temperature environments, the color of PIR ASA will not fade, and the material will not be embrittlement, extending the service life.

High strength and impact resistance: suitable for applications that need to withstand large impact forces and high loads.

Good processing performance: support a variety of processing methods, such as injection molding, extrusion, etc., suitable for different shapes, sizes and application requirements.

Environmental protection: made by recycling waste materials, in line with the concept of green production and sustainable development.

Economy: The use of recycled materials helps reduce production costs and provides companies with a competitive price advantage.

Production and technology advantages

Advanced recycling process: Modern recycling technology and optimized processing technology are used to ensure the high purity and excellent performance of PIR ASA materials.

Wide applicability: PIR ASA ADAPTS to the needs of a variety of industries and applications, and can provide high-performance solutions to meet the special requirements of different industries for materials.