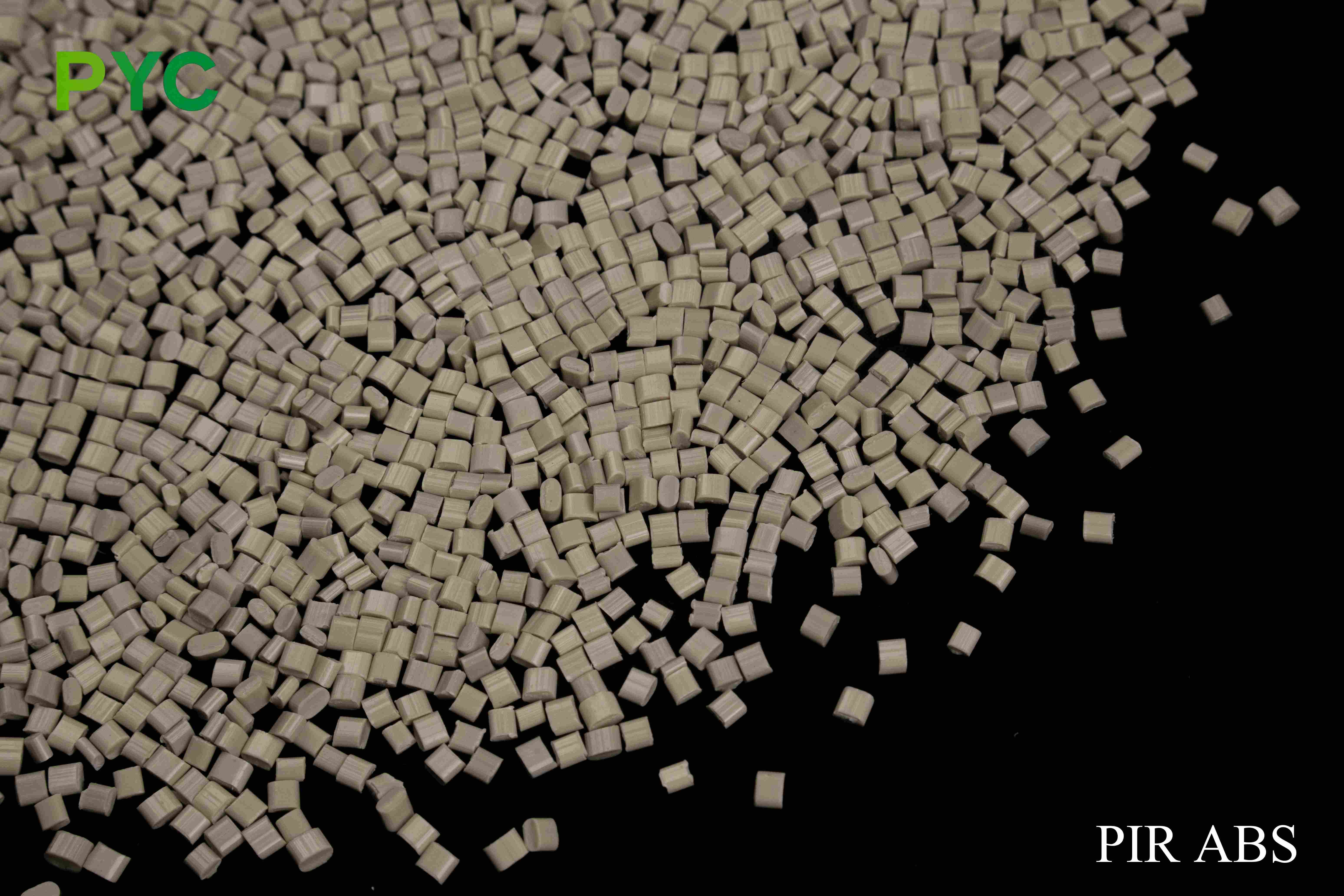

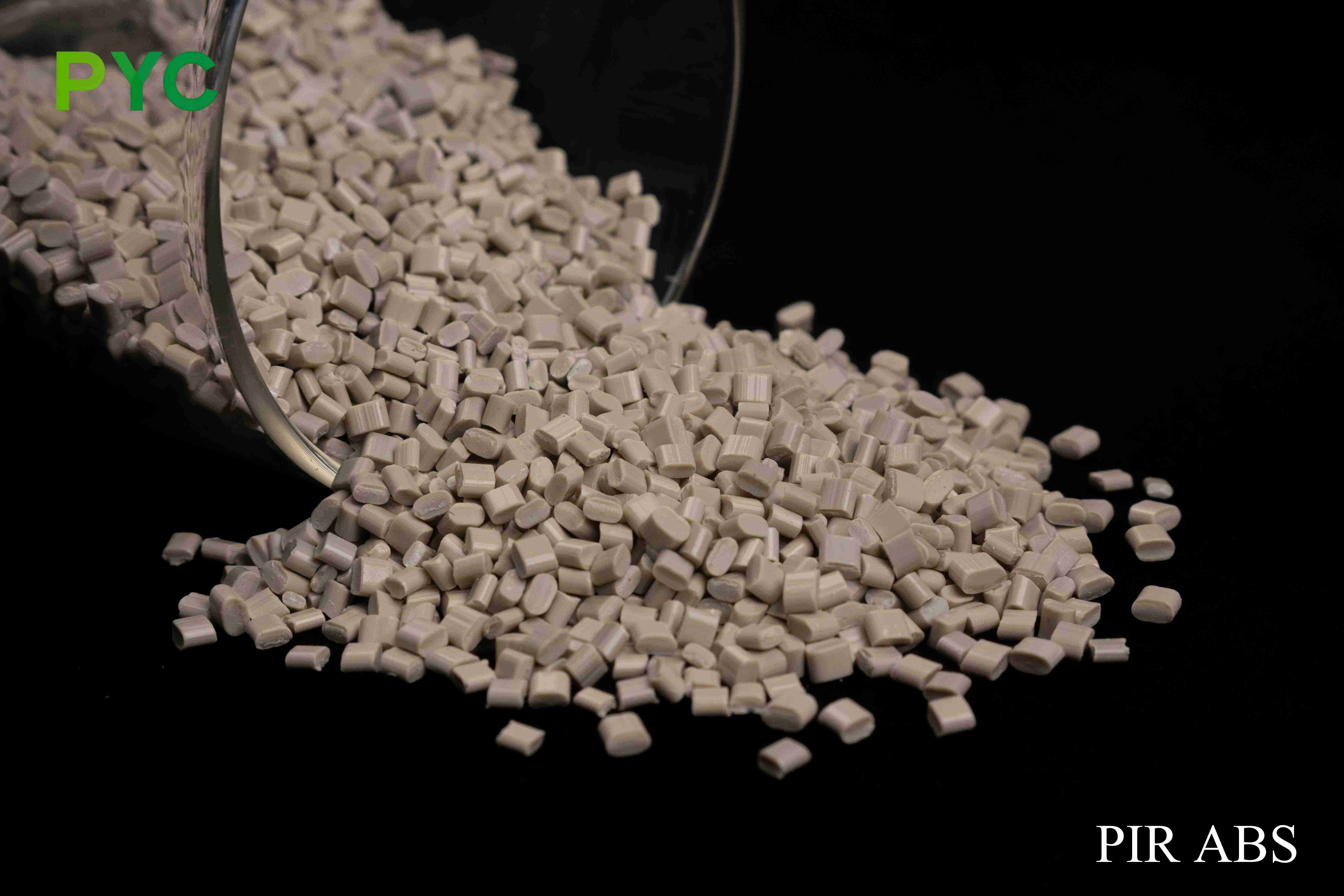

PIR ABS

PIR ABS (PostIndustrial Recycled Acrylonitrile Butadiene Styrene) - Post-industrial recycled ABS

PIR ABS (Postindustrial recycled acrylonitrile butadiene styrene) is an environmentally friendly plastic produced by recycling industrial waste ABS (acrylonitrile butadiene styrene) material. ABS is a widely used engineering plastic, because of its good mechanical properties, impact resistance, easy processing and low cost, in the automobile, home appliances, electronics, toys and other industries have a wide range of applications. PIR ABS uses the waste generated in the industrial production process (such as production residues, scraps, etc.) to be recycled and treated, reducing the emission of plastic waste and providing a sustainable solution for enterprises.

Product Details

1. High-quality recycled feedstock sources

The recycled feedstock for PIR ABS is mainly from waste ABS materials from industrial production, including:

Production waste: such as ABS injection molding edges and corners, discarded plastic parts, edge and corner waste in the production process.

Waste ABS products: such as used appliance shells, automobile interior parts, toys and so on.

Waste packaging materials: such as discarded ABS boxes and containers.

These waste materials are rigorously screened, cleaned, processed and converted into high quality PIR ABS feedstock to ensure its performance and environmental friendliness.

2. Strict quality control

PIR ABS undergoes a series of stringent quality controls during the manufacturing process, including testing of the material's tensile strength, impact toughness, dimensional stability, and appearance to ensure consistent and reliable product performance. Each batch of material undergoes rigorous testing to ensure compliance with industry standards and to meet the needs of different application scenarios.

3. Excellent performance

High Impact Resistance: PIR ABS has excellent impact resistance and can maintain good toughness and strength under external forces, making it suitable for applications that require impact resistance.

Ease of processing: PIR ABS can be easily produced in various shapes and sizes through injection molding, extrusion, and other processing methods to meet different manufacturing needs.

Good dimensional stability: PIR ABS has good dimensional stability, small shape and size deformation during processing, suitable for products requiring high precision.

Good surface finish: PIR ABS has a flat and smooth surface, suitable for products with high appearance requirements.

4. Environmental protection and sustainability

By recycling discarded ABS materials, PIR ABS reduces the need for new raw materials and helps minimize the accumulation of plastic waste, in line with the concepts of environmental protection and sustainable development. The recycling process not only reduces production costs, but also reduces environmental pollution from waste materials, helping to promote a green economy.

5. Cost-effectiveness

Because PIR ABS is made from recycled materials, it is less expensive to produce than new ABS, providing companies with a more economical plastics solution. The use of PIR ABS helps to reduce production costs and increase your competitiveness in the marketplace.

Application area

Automotive industry: PIR ABS is widely used in automotive interior parts, dashboards, lamp shells, etc., with excellent impact resistance and good dimensional stability, it can provide long-term durability in the interior environment.

Home appliance industry: Used in the production of home appliance shell, TV shell, refrigerator parts, etc., to provide excellent mechanical strength and appearance.

Electronic products: Used in electronic product housings, computer cases, mobile phone accessories, etc., PIR ABS's excellent processability and good appearance make it an ideal material for the electronics industry.

Toy industry: Used in the production of plastic toy shells, accessories, etc., to ensure the impact resistance and safety of the material.

Packaging industry: Used for the production of packaging containers, transportation boxes, etc., to meet the requirements of the packaging industry for strength, stability and appearance. Product advantages

High impact resistance: PIR ABS has strong impact resistance and can withstand external shocks and impacts, which is suitable for applications requiring high durability.

Good processing performance: PIR ABS can be processed by conventional processing technology to adapt to the manufacturing needs of various shapes.

Environmental protection: Through recycling waste materials production, effectively reduce the pollution to the environment, in line with the requirements of sustainable development.

Economy: Compared with the new ABS material, the production cost of PIR ABS is more competitive, which can help enterprises reduce production costs.

Good appearance effect: PIR ABS has good surface finish and processability, which is suitable for products with high appearance requirements.

Production and technical advantages

Advanced recycling process: PIR ABS adopts modern recycling technology to extract high-quality raw materials from discarded ABS materials to ensure its stable performance.

A wide range of processing adaptability: PIR ABS can be manufactured by injection molding, extrusion and other processing methods to adapt to the production needs of different types of products.