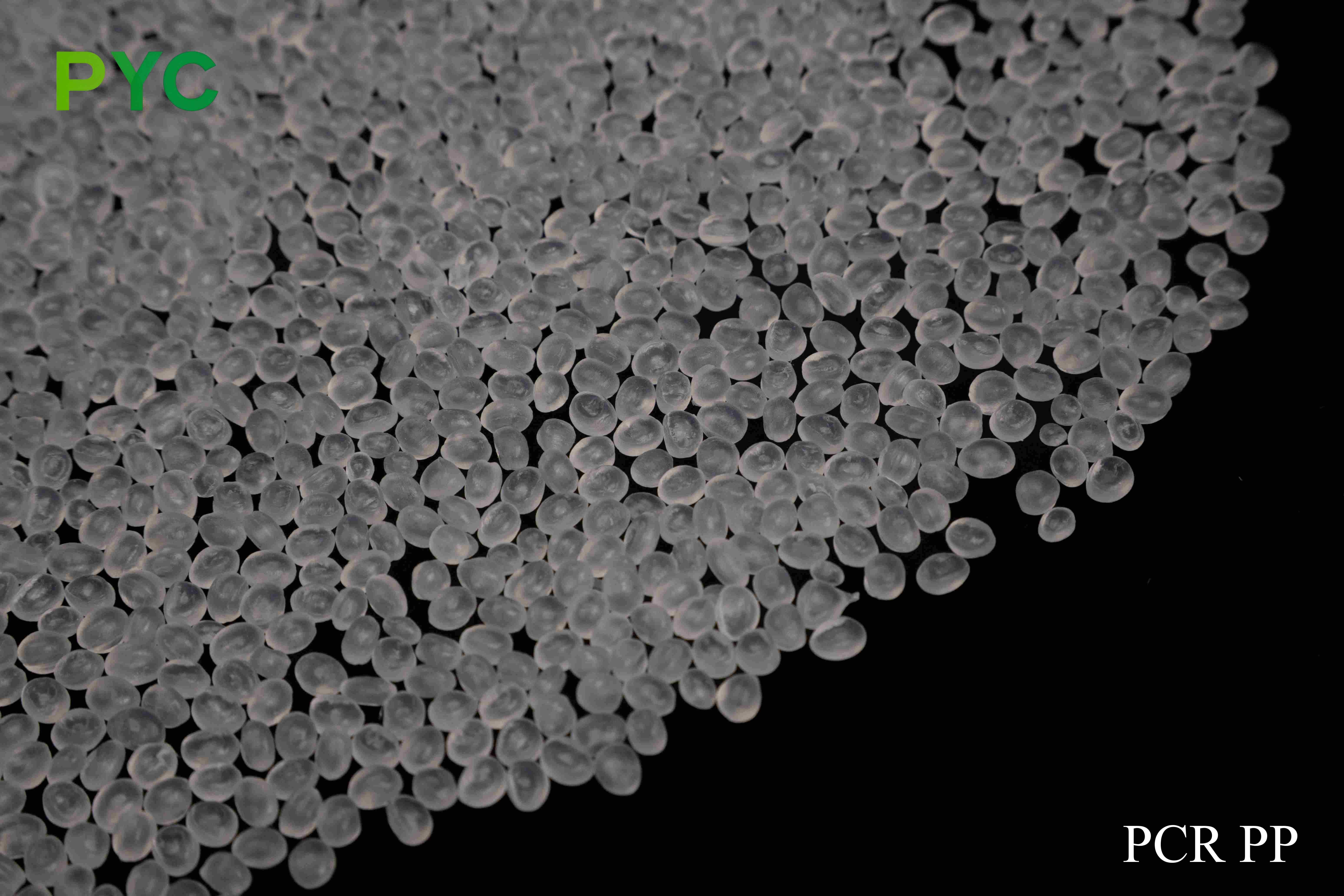

PCR PP

PCR PP (Post Consumer Recycled Polypropylene) is an environmentally friendly plastic made by recycling post-consumer waste polypropylene (PP) material. PP has high strength, chemical resistance, heat resistance and impact resistance, and is widely used in packaging, automotive, home, medical and other fields. Using recycled PP materials, PCR PP not only helps to reduce the burden of plastic waste on the environment, but also provides enterprises with a choice of raw materials with double advantages of environmental protection and economy.

Product Details

Sources of recycled raw materials and their specific descriptions: Housing for household appliances

The shell of many household appliances is made of polypropylene material. These discarded electrical housings are recycled and can be used as a raw material source for high-quality PCR PP.

Examples of recycled sources:

Washing machine casing: A washing machine whose life has expired or is damaged, the casing is usually made of polypropylene and can be recycled for recycling.

Rice cooker housings: Discarded rice cooker housings are also a great source of polypropylene for recycling.

Automotive interior trim

Polypropylene materials are used extensively in automotive interiors, especially in instrument panels, door panels and other components. These parts can be recycled after the car is scrapped and used as raw materials for PCR PP.

Examples of recycling sources:

Dashboards: The dashboards of end-of-life vehicles are usually made of polypropylene and can be recycled after recycling.

Door upholstery panels: Door upholstery panels are also an important application area for polypropylene and can be used as recycled raw materials after being discarded.

Waste household items

Many household items, such as plastic furniture, storage bins, etc., are made of polypropylene. These discarded household items are recycled and can be used to produce high-quality PCR PP.

Examples of recycled sources:

Plastic chairs: Discarded plastic chairs can be used as raw materials for polypropylene recycling.

Storage bins: Broken or discarded plastic storage bins are also a source of recycling.

ecycling process

The recycling process for PCR PP usually includes the following steps:

Collection and sorting: The discarded polypropylene products are collected and sorted according to the material and the degree of contamination.

Cleaning and disinfection: The recycled plastics are cleaned to remove impurities and contaminants, and sterilized if necessary.

Crushing and granulation: The cleaned plastic is crushed and then processed into pellets by a granulator.

Quality inspection: The quality inspection of the recycled particles is carried out to ensure that it meets the relevant standards and application requirements.

Excellent mechanical properties

PCR PP inherits the excellent characteristics of polypropylene, with high tensile strength, excellent impact resistance and better heat resistance. Even under long-term use and high load conditions, PCR PP still maintains good mechanical properties and is suitable for a variety of engineering applications.

Environmental and sustainability

PCR PP, as a recycled material, helps reduce the accumulation of plastic waste and complies with increasingly stringent environmental regulations around the world. By recycling waste PP materials, the need for new resources is reduced, helping to reduce carbon emissions and promote circular economy and sustainable development.

Chemical and weather resistance

PCR PP has good chemical resistance, can withstand the erosion of many chemicals, and is particularly suitable for the manufacture of products such as chemical containers and pipes. In addition, it also has a strong resistance to ultraviolet light, suitable for long-term exposure to outdoor applications.

Excellent processing adaptability

PCR PP can be molded by a variety of processing methods (such as injection molding, extrusion, blow molding, etc.) to adapt to different production needs. Its excellent fluidity and processing properties make it suitable for use in a variety of complex shape product designs.

Fields of Application:

Packaging industry

PCR PP is widely used in the manufacture of various types of packaging materials, such as food packaging containers, bottle caps, pallets, packaging boxes, etc. Its high strength and chemical resistance allow these packaging materials to effectively protect the contents and extend the shelf life.

Automotive industry

PCR PP is widely used in the automotive industry, mainly for the manufacture of automotive interior parts, shells, instrument panel components, etc. Its light weight, high strength and heat resistance make PCR PP an ideal material for lightweight automotive design and environmental protection requirements.

Home furnishing industry

In the home furnishing field, PCR PP is widely used in the production of plastic furniture, containers, storage boxes, etc. Its durability and impact resistance make these products perform well in daily use and meet environmental requirements.

The medical industry

PCR PP can also be used to manufacture casings for medical devices, pharmaceutical packaging and disposable medical supplies. Its antibacterial properties and good tolerance to chemicals make it an indispensable material in the medical industry.

Performance advantages and technical features:

High tensile strength and impact resistance

PCR PP has very good tensile strength and is not easy to deform even under high load conditions. At the same time, its impact resistance is strong, and it can maintain good shape and function under high impact forces.

Chemical Resistance and Corrosion resistance

PCR PP can resist the erosion of a variety of chemicals, such as acids, alkalis, oils, etc., and is ideal for the production of chemical containers, pipelines and other applications with corrosion resistance requirements.

Good heat resistance and weather resistance

PCR PP has good heat resistance, can withstand higher temperatures without losing strength, suitable for high temperature environment. Its strong weather resistance, suitable for outdoor environment, not easy to be affected by ultraviolet light, rain and other factors.

Excellent processability PCR PP has excellent processability and can be processed by injection molding, extrusion and other common processes to adapt to different shape and functional requirements of product design.

Environmental protection and cost effectiveness:

Reduce plastic waste, promote circular economy

The use of PCR PP helps to reduce the accumulation of plastic waste, promote the recycling and reuse of waste plastics, reduce the dependence on new raw materials, promote the recycling of resources, in line with the concept of environmental protection and sustainable development.

Reduce production costs

PCR PP uses recycled materials, the production cost is usually lower, compared with the new PP, the price of PCR PP is more competitive in the market. By using PCR PP, enterprises can not only reduce production costs, but also improve their environmental image, in line with the requirements of green production.