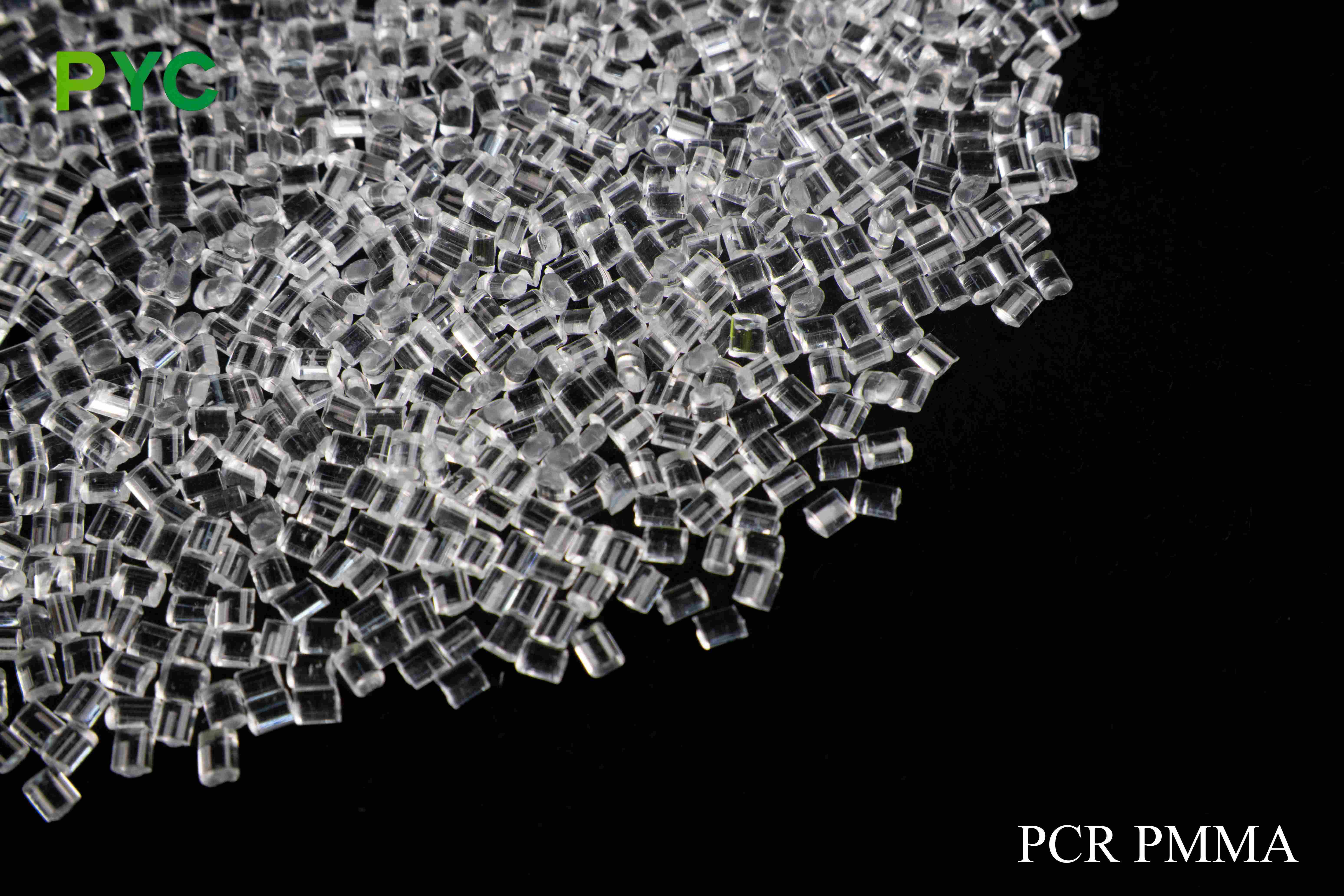

PCR PMMA

PCR PMMA (Post Consumer Recycled polymethyl methacrylate) is an environmentally friendly plastic made by recycling post-consumer PMMA materials. PMMA, commonly referred to as Plexiglass or acrylic, is a material with excellent transparency, weather resistance, and impact resistance. By recycling used PMMA products, it not only reduces the environmental burden, but also provides a sustainable source of raw materials for the manufacture of high-quality new products.

Product Details:

Recycled raw materials mainly come from the following areas:

Waste billboards and signboards

PMMA material is widely used in the production of billboards, signs, display stands, etc., because it has excellent light transmission and anti-ultraviolet properties. As billboards are replaced or removed, discarded advertising materials become an important source of recycling. Used advertising billboards are usually classified as PMMA during the dismantling process and are cleaned and screened before being converted into high-quality PCR PMMA for use in new advertising materials or other plastic products.

Examples of recycling sources:

Advertising sign

Display stand

Road signs and signs

Shop window signs

Scrap car light fixtures

PMMA material is widely used in the automotive industry in the shell of lamps, taillights, turn signals and other lamps, because of its good light transmission and weather resistance. With the growth of the service life of the car, the discarded car lamps become the recycling source of PCR PMMA. After the recovered automotive lamps are disassembled, cleaned, screened and other processes, high-quality PCR PMMA raw materials can be obtained, which are widely used in auto parts or other optical applications.

Examples of recycled sources:

Car front and rear light shells

Headlight housings

Car indicators, brake lights, etc

Discard electronics housings

PMMA is widely used in the housing of electronic products such as televisions, monitors, lamps, projectors, etc. As electronics are scrapped and phased out, electronic housings become an important recycling source for PCR PMMA. Discarded electronic casings are usually disassembled and treated to extract PMMA material, which is then converted into new recycled materials after processing and quality control.

Examples of recycled sources:

TV cover

Computer monitor housing

Projector housing

Luminaire housing

Scrap appliances and lighting fixtures

In addition to the shell of electronic products, PMMA is also commonly used in household appliances and lighting equipment, especially some optically transparent lampshades, lamp covers, lighting pipes, etc. These appliances and lighting fixtures are usually phased out after a period of use and turned into scrap. Waste lighting fixtures and appliance housings are recycled, cleaned and processed to form new PCR PMMA raw materials that continue to be used in other industrial and consumer products.

Examples of recycled sources:

Lighting fixture outer cover

Lamp tube

Housing for lighting equipment

Home appliance display housing

Scrap furniture and decorations

PMMA is also often used in furniture and decorations, especially in modern home and office environments, acrylic furniture, lamps, display shelves and other widely used PMMA materials. With the replacement or elimination of furniture and decorations, discarded PMMA materials become one of the sources of recycling. After recycling, PMMA materials are often cleaned, screened, and converted through processing into new recycled plastic materials for the production of new furniture, decorations, or other consumer goods.

Examples of recycled sources:

Acrylic furniture

Display shelves

Decorations and accessories

Clear cabinets and display stands

Industrial waste and production scraps

In the production process of PMMA, there is often some scrap or waste material, which is usually collected from the production line and recycled. Since these industrial wastes usually come from the production process and contain fewer impurities, they can be quickly converted into high-quality PCR PMMA after recycling, which is widely used in the production of various plastic products.

Examples of recycled sources:

Scraps from the injection molding process

Scraps from the extrusion process

Excess material from the blow molding process

Recycling process

Recycled PCR PMMA materials usually go through several steps:

Screening and sorting: The discarded PMMA material is first initially screened by manual or automated means to remove other plastic impurities.

Cleaning and decontamination: The recycled PMMA material is thoroughly cleaned to remove oil, labels, coatings and other contaminants, ensuring the purity of the recycled material.

Crushing & graining: The cleaned PMMA material is broken into small particles to facilitate further processing.

Quality testing: Each batch of recycled PCR PMMA is subjected to strict quality control, including transparency, UV resistance linearity, weather resistance, etc., to ensure that it meets industry standards.

Reprocessing into new products: After processing, PCR PMMA materials can be used to produce new transparent plastic products, which are widely used in advertising, lighting, construction and other fields.

Application: PCR PMMA is widely used in advertising signs, architectural decoration, transportation facilities, home appliance shell and optical products, etc., to meet the multiple needs for transparency, durability and beauty.

Performance and advantages: PCR PMMA inherits the excellent properties of PMMA, such as high light transmittance, good impact resistance and weather resistance, while reducing the environmental burden through recycling, in line with the concept of sustainable development.

Production and technical advantages: The use of advanced recycling technology and production process, to ensure the quality stability of PCR PMMA and processing adaptability, to provide customers with customized solutions.

Environmental and cost effective: The use of PCR PMMA helps to reduce production costs while reducing the need for new resources, in line with environmental regulations and market demand for sustainable products.

Overall, PCR PMMA, with its excellent performance, environmental benefits and wide range of application scenarios, has become a highly favored recycled material in the market, providing a solid foundation for companies to achieve green production and sustainable development goals.