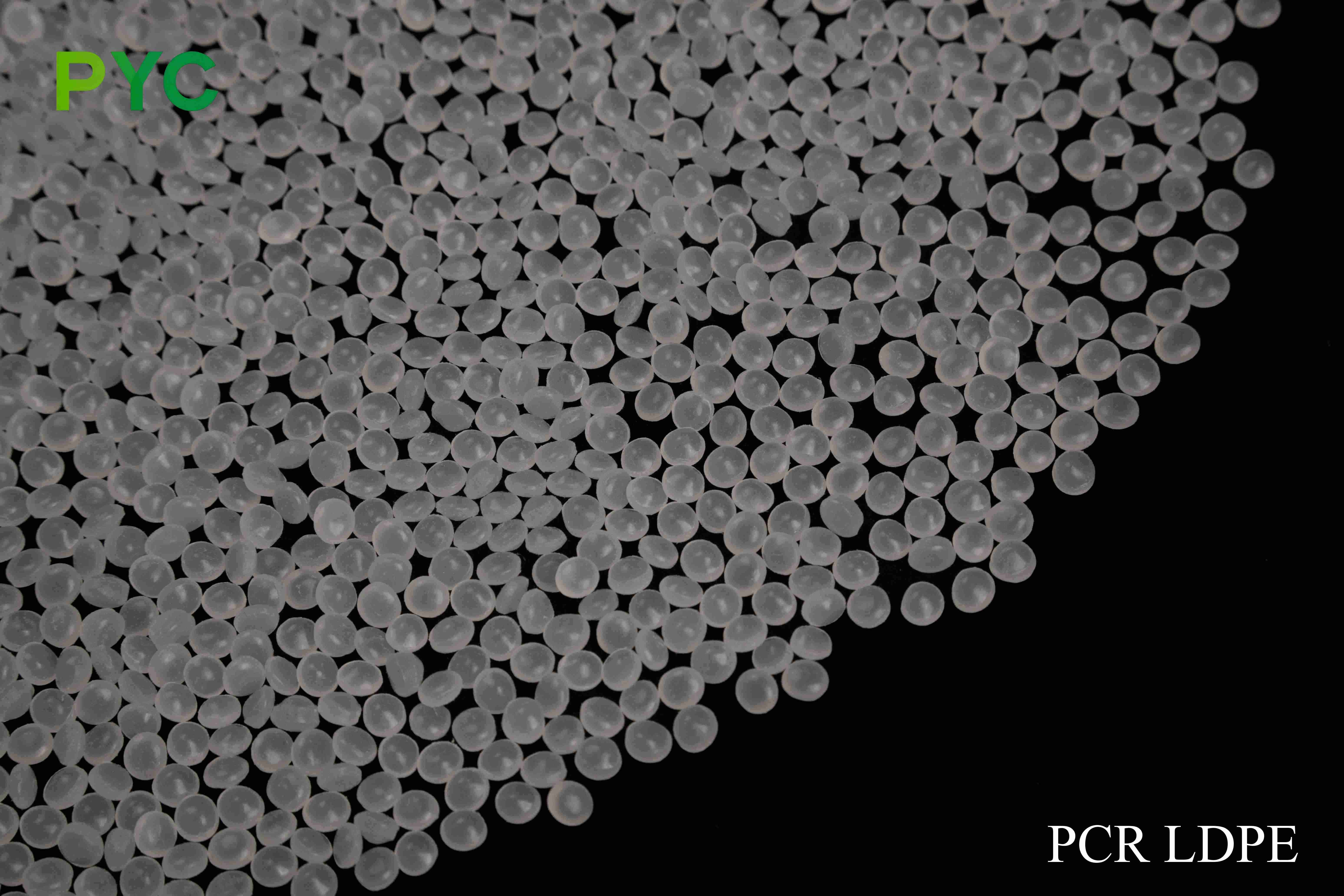

PCR LDPE

PCR LDPE (Post Consumer Recycled Low Density Polyethylene) is an environmentally friendly plastic produced by recycling post-consumer waste low density polyethylene (LDPE) material. LDPE, as a highly flexible and transparent plastic, is widely used in packaging and other everyday items. By recycling LDPE materials, PCR LDPE not only helps reduce the accumulation of plastic waste, but also provides companies with an economical and practical alternative that meets environmental requirements.

Product Details

Recycled raw material source, specific description:

Waste plastic packaging materials

LDPE is an important material in the packaging industry, widely used in the production of various flexible packaging products, especially in food, consumer goods and other industries.

Discarded plastic packaging is one of the main sources of PCR LDPE.

Examples of recycling sources:

Plastic shopping bags: Clear plastic shopping bags and bulk goods bags used in supermarkets and stores, most of which are made of LDPE, are recycled to become PCR LDPE raw materials after use.

Food packaging film: film packaging of food such as vegetables, fruits, snacks, especially transparent packaging film and plastic wrap used in the food industry.

Waste express bags: plastic bags in the e-commerce industry (especially express bags, plastic bags, etc.), often use LDPE or LLDPE (linear low density polyethylene) materials, after recycling as PCR LDPE.

Bubble film and foam packaging: such as bubble film and foam packaging materials commonly used in the express industry, but also an important source of LDPE.

Agricultural plastic film

The agricultural industry widely uses LDPE materials for greenhouse film, mulch film, and other agricultural plastic film. With a large amount of plastic film discarded in agricultural production, these discarded LDPE materials are recycled and become an important source of PCR LDPE.

Examples of recycled sources:

Agricultural mulch: A plastic film used to cover soil that maintains soil moisture and temperature and reduces weed growth. LDPE or LLDPE materials are usually used for mulch.

Greenhouse film: Clear plastic film used in greenhouses and greenhouses, with good light transmission and flexibility, usually LDPE material.

Agricultural plastic pipes: some farmland irrigation pipes and agricultural pipes may also be LDPE materials, which can also be recycled after waste.

Discard plastic bottles and containers

While HDPE (high density polyethylene) is more commonly used in the production of bottles and containers, there are lightweight containers and bottles that use LDPE, especially in the field of household chemicals, cleaning supplies, etc. These waste containers are recycled and processed to become one of the sources of PCR LDPE.

Examples of recycled sources:

Detergent bottles: plastic bottles for household chemicals such as laundry detergent and dish soap, some of which use LDPE.

Cosmetics and skincare bottles: Some cosmetics and skincare bottles may also use LDPE, especially clear and soft packaging containers.

Other containers: such as some plastic packaging soft drink bottles, drinking water bottles, etc.

Discard consumer and daily plastic products

With the widespread use of plastic products in the daily life of consumers, discarded household plastic products also provide a source of PCR LDPE. Including household plastic appliances, toys and consumer goods, etc.

Examples of recycling sources:

Children's toys: Some children's plastic toys and play utensils may use LDPE materials, especially soft, bendable parts.

Plastic storage boxes: such as soft plastic storage boxes for household organizing, garbage bags, etc.

Household items: such as some plastic mops, brooms and other cleaning supplies, some products use LDPE.

Industrial waste and production scraps

In the production process of LDPE, there are usually some scraps and wastes, which are recycled and treated to become high-quality PCR LDPE raw materials.

Examples of recycled sources:

Waste in the production process: In the production process of injection molding, blow molding, extrusion, etc., unused LDPE materials (such as scrap and scraps) can be recycled and reused.

The waste of polyethylene film: the waste generated during the film manufacturing process, is also recycled and processed into PCR LDPE.

Scrap building and packaging materials

Although LDPE is used less in the construction field, it still appears in some membranes and plastic parts used in construction. Discarded construction and packaging materials are also one of the sources of PCR LDPE.

Examples of recycled sources:

Building waterproof film: Some waterproof materials use LDPE, especially in softer, corrosion-resistant plastic films.

Waterproof materials and films: such as film packaging in the construction field, especially those used for ground cover and protection of plastic films.

Recycling processes

The recycling process of PCR LDPE usually includes the following key steps:

Collection and sorting: The discarded LDPE material is collected through the recycling station, garbage sorting and recycling system, and the initial sorting is performed.

Cleaning and decontamination: Remove oil, stains, adhesives and other impurities from the plastic surface to ensure the purity of the material.

Pulverization and granulation: The recycled plastic material is pulverized and converted into a granular form for subsequent processing.

Quality testing and screening: Standardized testing to ensure that the performance, strength and toughness of recycled materials meet industry standards.

Reprocessing and application: Recycled PCR LDPE is processed into new particles or sheets, which are widely used in packaging, agriculture, building materials and other fields.

Fields of Application:

Packaging industry

PCR LDPE is widely used in the production of transparent packaging film, plastic bags, food packaging bags, garbage bags, etc. Its high transparency and flexibility make it an ideal packaging material to effectively protect the contents and extend the shelf life of the product.

Agricultural industry

In the agricultural sector, PCR LDPE is widely used in the production of agricultural film, mulch film, greenhouse covering film, etc. Its UV resistance and weather resistance make it have good stability in the outdoor environment, and can improve the protection efficiency of crop growth.

Construction industry

PCR LDPE is used in the production of building film, isolation film, waterproof film and other materials. Its excellent flexibility and impact resistance make these materials have better adaptability and stability in building construction.

Consumer goods and everyday goods

PCR LDPE can also be used in the production of daily consumer goods, such as packaging bags, shopping bags, hygiene products, etc. Its softness and durability make these products more durable in everyday use and less prone to damage.

Performance Advantages and Technical features:

High flexibility and low temperature stability

PCR LDPE has very good flexibility and can maintain excellent toughness and strength even at low temperatures, and is suitable for various applications in low temperature environments.

Uv Resistance and weather resistance

PCR LDPE has excellent UV resistance and weather resistance, can be exposed to sunlight for a long time without aging, and is very suitable for outdoor applications, such as agricultural film, building film, etc.

Good processability

PCR LDPE processing performance is very good, can be processed through a variety of molding processes (such as injection molding, blow molding, extrusion, etc.), to adapt to the requirements of various shapes and structures, widely used in the manufacture of different products.

Environmental protection advantages

As a recycled material, PCR LDPE can effectively reduce the dependence on petroleum resources, reduce carbon emissions in the production process, and provide enterprises with sustainable economic solutions.

Environmental protection and cost effectiveness:

Reducing plastic waste and saving resources

Using PCR LDPE helps to reduce the accumulation of plastic waste while reducing the reliance on new raw materials and reducing environmental pollution. By recycling waste plastics, PCR LDPE promotes the realization of a circular economy.

Reduced production costs

Because PCR LDPE uses recycled materials, the production cost is lower than the traditional new LDPE material, providing enterprises with a more economical and practical solution, especially in the increasingly stringent environmental requirements of the market has significant competitiveness.