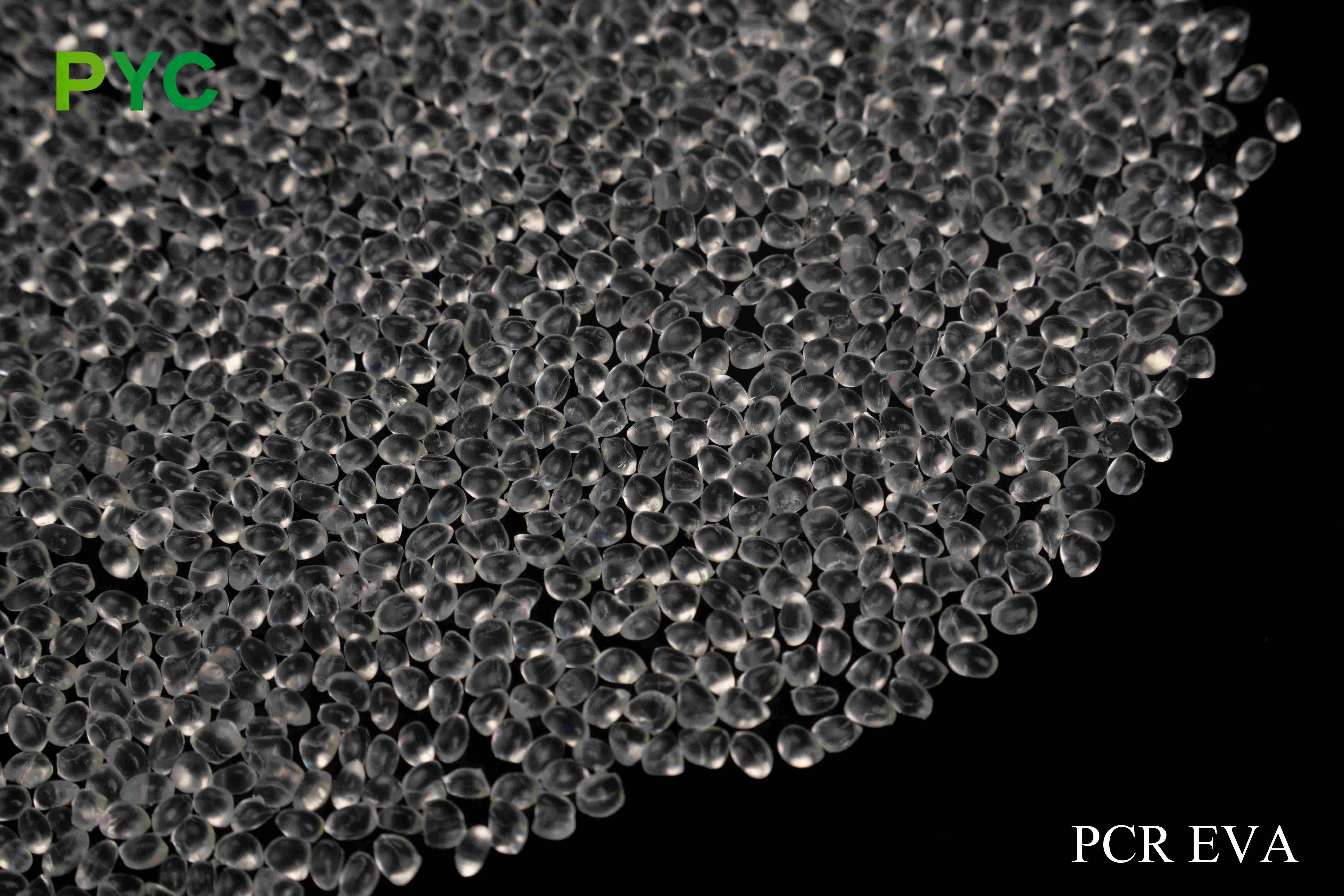

PCR EVA

Our PCR EVA is made from high-quality recycled materials, providing a sustainable alternative for various applications. By utilizing post-consumer recycled content, this material reduces the reliance on virgin plastics, contributing to the circular economy while maintaining the high-performance characteristics of traditional EVA.

PCR EVA (Recycled vinyl vinyl acetate copolymer) product details

1. High-quality recycled feedstock sources

Waste shoe materials

EVA is widely used in footwear products in areas such as midsoles and insoles. Waste shoe materials are an important source of high quality PCR EVA.

Recycling Source Example:

Footwear Production Waste: The trimmings and defective products generated during the production of footwear.

Used footwear products: Used footwear products discarded by consumers.

Waste packaging materials

EVA is used in the manufacture of a variety of packaging materials such as foam packaging and protective pads. These waste packaging materials are recycled and processed as a source of raw material for high quality PCR EVA.

Recycling Source Example:

Foam Packaging: EVA foam packaging for electronic products, home appliances, etc.

Protective pads: EVA protective pads for furniture transportation.

Waste solar cell encapsulation film

EVA is widely used as an encapsulation film for solar cells. EVA encapsulation film from discarded or end-of-life solar modules is a potential source of PCR EVA.

Recycling Source Example:

End-of-life solar modules: from which EVA encapsulation film is recovered.

The recycling process for high quality PCR EVA typically includes the following steps:

Collection and Sorting: Waste EVA products are collected and sorted according to material and degree of contamination.

Cleaning and pre-treatment: The recycled EVA material is cleaned to remove impurities and contaminants.

Crushing and melting: The cleaned EVA material is crushed and subsequently processed into recycled pellets through the melting process.

Filtration and granulation: Filtering technology is used to remove tiny impurities in the molten EVA to ensure the purity of the recycled material, and then granulation is carried out.

Quality testing: quality testing of recycled pellets to ensure that their performance meets the relevant standards and application requirements.

2. Strict quality control

PCR EVA follows a strict quality control system during the manufacturing process to ensure that each batch meets stringent performance standards. Each batch undergoes a series of quality tests, such as tensile strength, impact resistance, melt flow index (MFI), etc., to ensure stable and consistent performance. The high quality control process ensures the reliability of the products and makes them suitable for application needs in multiple industries.

3. Excellent performance characteristics

Good Flexibility: PCR EVA has excellent flexibility and maintains good performance at low temperatures, making it ideal for flexible products such as elastic films and shoe materials.

Excellent UV resistance: PCR EVA has strong UV resistance, even under sunlight exposure, it can effectively prevent aging and discoloration and maintain its long-term stability.

High Transparency: PCR EVA has good transparency, which is suitable for products that require high visual effect and can provide better appearance and display effect.

Low-temperature resistance: excellent low-temperature flexibility, can still maintain its physical properties in the cold environment.

4. Environmental protection and sustainability

As a recycled material, PCR EVA helps reduce resource waste and environmental pollution by utilizing waste plastics. Compared with using brand new raw materials, PCR EVA significantly reduces carbon emissions and energy consumption in the production process, which is in line with green requirements and promotes global sustainability goals.

5. Cost-effectiveness

Thanks to the use of recycled raw materials, PCR EVA can be produced at a lower cost, providing companies with a cost-effective solution. By using PCR EVA, companies can reduce raw material costs while maintaining high product quality and increasing market competitiveness.

Application Areas:

Shoe material industry:

Soles and insoles: PCR EVA is widely used in the footwear industry in the production of sole, insoles and other components. Due to its flexibility and comfort, PCR EVA can provide excellent cushioning effect, and durable, lightweight, very suitable for sports shoes, casual shoes and other footwear products manufacturing.

Shoelaces and accessories: The softness and high elasticity of PCR EVA make it an ideal material for accessories such as shoelaces, uppers, etc.

Packaging Industry:

Flexible packaging materials: PCR EVA is widely used in the production of flexible packaging materials, especially food packaging, cosmetic packaging and other products. Its high transparency and excellent anti-ultraviolet ability enable it to protect the contents of the packaging while providing a good appearance.

Foam material: PCR EVA can also be used to produce foam material, widely used in buffer packaging, protective film and other fields.

Automotive industry:

Automotive interior parts: PCR EVA has softness and UV resistance, which is suitable for the production of car seats, interior panels, roofs and other components, which can improve comfort and durability.

Sealing material: Due to its good sealing performance, PCR EVA is suitable for car doors and Windows sealing strip and other accessories, can effectively prevent external pollutants from entering the car.

Construction industry:

Sound insulation and shockproof materials: PCR EVA is used in the construction industry for sound insulation materials, shockproof MATS and other products, which can effectively reduce noise transmission and vibration, and improve the comfort of living environment.

Waterproof membrane and sealing strip: PCR EVA has excellent water resistance and elasticity, suitable for waterproof membrane, sealing strip and other building applications, to help improve the waterproof effect of buildings.

Sports Equipment and Consumer Goods:

Sports equipment accessories: PCR EVA is widely used in the manufacturing of sports equipment accessories, such as MATS, protective gear, handles, etc., because of its soft, durable and comfortable.

Stationery and daily plastic products: Due to its processing performance and environmental protection characteristics, PCR EVA is suitable for the production of stationery, toys, household goods and other consumer goods.

Product performance and advantages:

Excellent flexibility and comfort: PCR EVA has good elasticity and flexibility, can maintain its excellent performance in different environments, suitable for the manufacture of a variety of flexible products.

Uv resistance and weather resistance: It has strong UV resistance, can resist the aging problem caused by sunlight and bad weather, and maintain long-term stability.

High transparency and appearance effect: PCR EVA provides high transparency and gloss, which can improve the visual effect and attractiveness of packaging, consumer goods and other products.

Environmentally friendly: The production of recycled materials not only reduces the demand for raw materials, but also reduces the accumulation of plastic waste, in line with the global trend of environmental protection and sustainable development.

Production and technical advantages:

Advanced recycling process: The production of PCR EVA relies on advanced recycling technology to ensure that its performance is similar to the original material, which improves the comprehensive performance and sustainability of the material.

Diversified processing methods: PCR EVA has good processing performance and can be processed by injection molding, extrusion, foam molding and other ways to adapt to different needs of product production.

Environmental protection and sustainability:

Green production: The use of recycled materials to help reduce the accumulation of plastic waste, while reducing the consumption of energy and resources in the production process, promoting sustainable development.

Reduce carbon footprint: The use of PCR EVA can effectively reduce carbon emissions and provide more environmentally friendly and economical solutions for enterprises and industries.