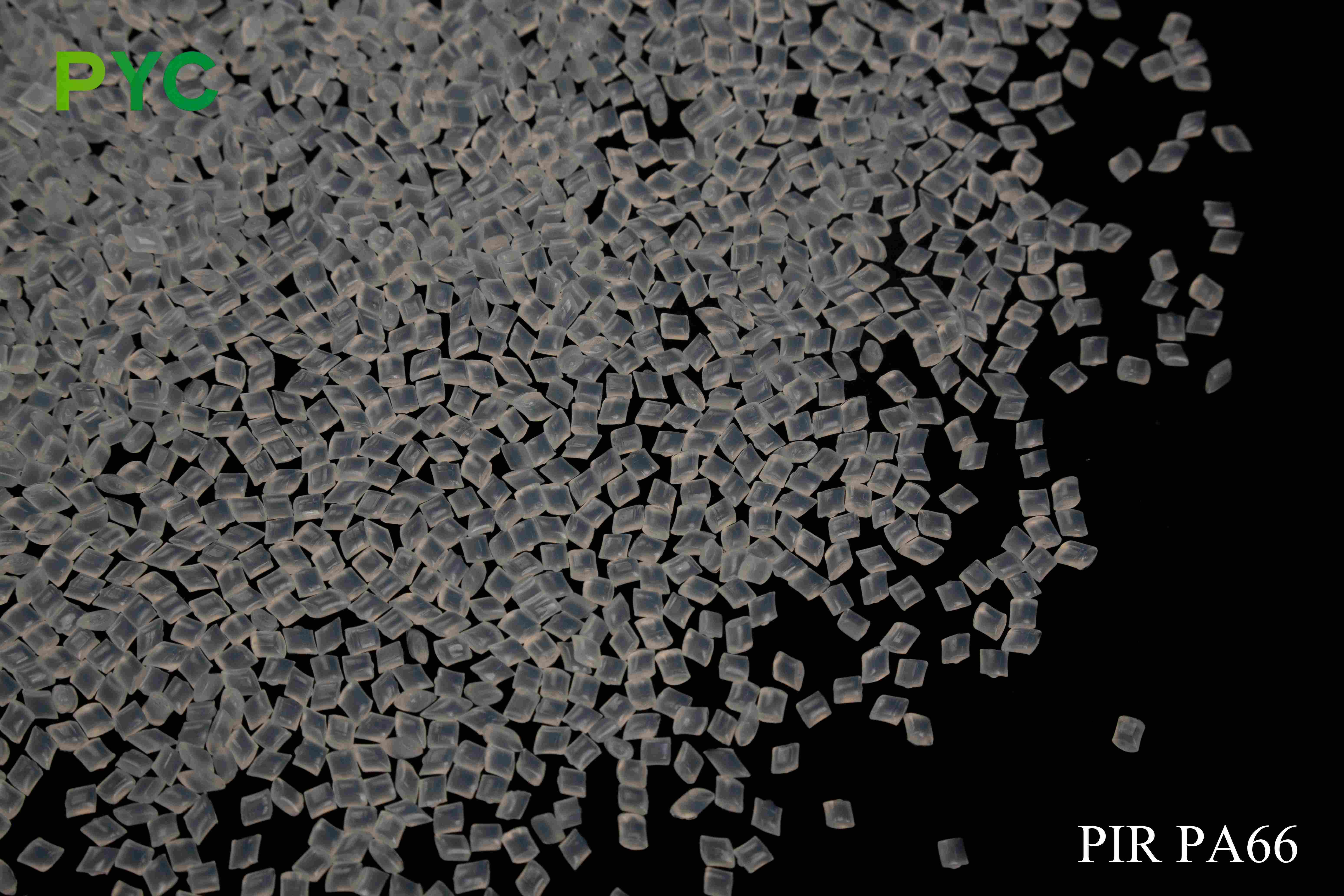

Industrial Plastic Recycled Nylon

Industrial Plastic Recycled Nylon (Industrial plastic recycled Nylon)

Industrial plastic Recycled Nylon (Recycled Nylon) is an environmentally friendly plastic made by recycling industrial waste nylon material for reprocessing. It has the excellent mechanical properties of nylon, such as high strength, wear resistance and chemical corrosion resistance, and is widely used in many industries such as automotive, electronics, electrical and textile.

Product Details

1. Specific sources of high-quality recycled raw materials:

Waste from the production process

In the production process of nylon products, some waste materials are often generated, such as runner materials, edges and non-conforming products. These wastes are unused and pure, and are an important source of high quality industrially recycled nylon.

Recycling Source Example:

Runner material: the part of the runner produced during the injection molding process.

Edge: The edge waste generated in the process of product trimming.

Non-conforming products: inferior or defective products produced in production.

Waste fibers and yarns from the textile industry

In the textile industry, the production and processing of nylon fibers and yarns generates a large amount of waste, such as waste fibers and waste yarns. These wastes are recycled and processed to produce high quality recycled nylon.

Recycling Source Example:

Waste fibers: Waste nylon fibers from the textile production process.

Waste Yarn: Waste nylon yarn from the textile process.

Waste from the plastics processing industry

In the plastics processing industry, the processing of nylon materials produces some waste materials, such as extrusion waste and trimming waste. These wastes can be recycled and processed to produce high quality recycled nylon.

Recycling Source Example:

Extrusion Waste: Waste produced during the extrusion of nylon materials.

Cutting edge waste: the waste produced in the process of cutting edge of nylon products.

Recycling

The recycling process for high quality industrial recycled nylon typically includes the following steps:

Collection and Sorting: Collect nylon wastes generated during industrial production and sort them according to material and color.

Cleaning and pre-treatment: The recycled nylon waste is cleaned to remove surface dust and impurities.

Crushing and melting: Cleaned nylon scrap is crushed and subsequently processed into recycled pellets through the melting process.

Filtering and pelletizing: Filtering technology is used to remove tiny impurities in the molten nylon to ensure the purity of the recycled material, which is then pelletized.

Quality testing: quality testing of recycled pellets to ensure that their performance meets the relevant standards and application requirements.

2. Strict quality control

Recycled nylon undergoes stringent quality control during the production process to ensure that each batch of material meets the relevant industry standards. A number of tests, such as tensile strength, impact resistance, abrasion resistance and thermal stability, are passed to ensure its reliability in different applications.

3. Excellent performance

High Strength and Abrasion Resistance: Recycled nylon has very high strength and abrasion resistance, making it especially suitable for high load and long-term friction applications.

Chemical resistance: Recycled nylon has good resistance to acids and alkalis and chemicals, suitable for use in harsh environments.

Good dimensional stability: With low moisture absorption, it can maintain excellent dimensional stability and is suitable for the manufacture of precision parts.

Good processing performance: Recycled nylon has good processability and can be processed in injection molding, extrusion and other ways to meet different needs.

4. Environmental protection and sustainability

By recycling nylon raw materials, the accumulation of waste can be reduced and the need for new raw materials can be reduced, which is an important initiative to promote circular economy and sustainable development. Recycling nylon not only reduces the consumption of resources, but also effectively reduces environmental pollution.

5. Cost-effectiveness

Recycled nylon is relatively inexpensive to produce and the cost of purchasing new material is significantly reduced through the recycling process. This allows companies to offer high-performance nylon products at more competitive prices.

Application area

Automotive industry: Used in automotive interior parts, seats, carpets and automotive parts, etc., to provide high strength and anti-wear properties.

Electronic industry: Used in the production of electronic products shell, switches, plugs, etc., with good chemical resistance and stability.

Textile industry: can be used in the production of nylon fiber, clothing, fishing nets, etc., to ensure the durability and strength of the fabric.

Industrial parts: suitable for the manufacture of mechanical parts, gears, bearings, etc., wear resistance and high strength.

Product Advantages

High strength and wear resistance: ideal for applications that withstand friction and high loads for a long time.

Chemical resistance: Suitable for chemical environment, acid and alkali resistance, corrosion resistance.

Good processability: Support injection molding, extrusion and other processing technology, suitable for complex shape and high-precision product manufacturing.

Environmental protection: Through recycling waste nylon products, help reduce the accumulation of plastic waste, in line with the requirements of sustainable development.

Economy: The use of recycled materials reduces production costs without sacrificing product quality and performance.

Production and technical advantages

Advanced recycling technology: modern recycling technology and processing technology are adopted to ensure the high purity and performance of recycled nylon.

A variety of processing methods: recycled nylon can be processed by injection molding, extrusion and other ways to meet different shapes and application requirements.