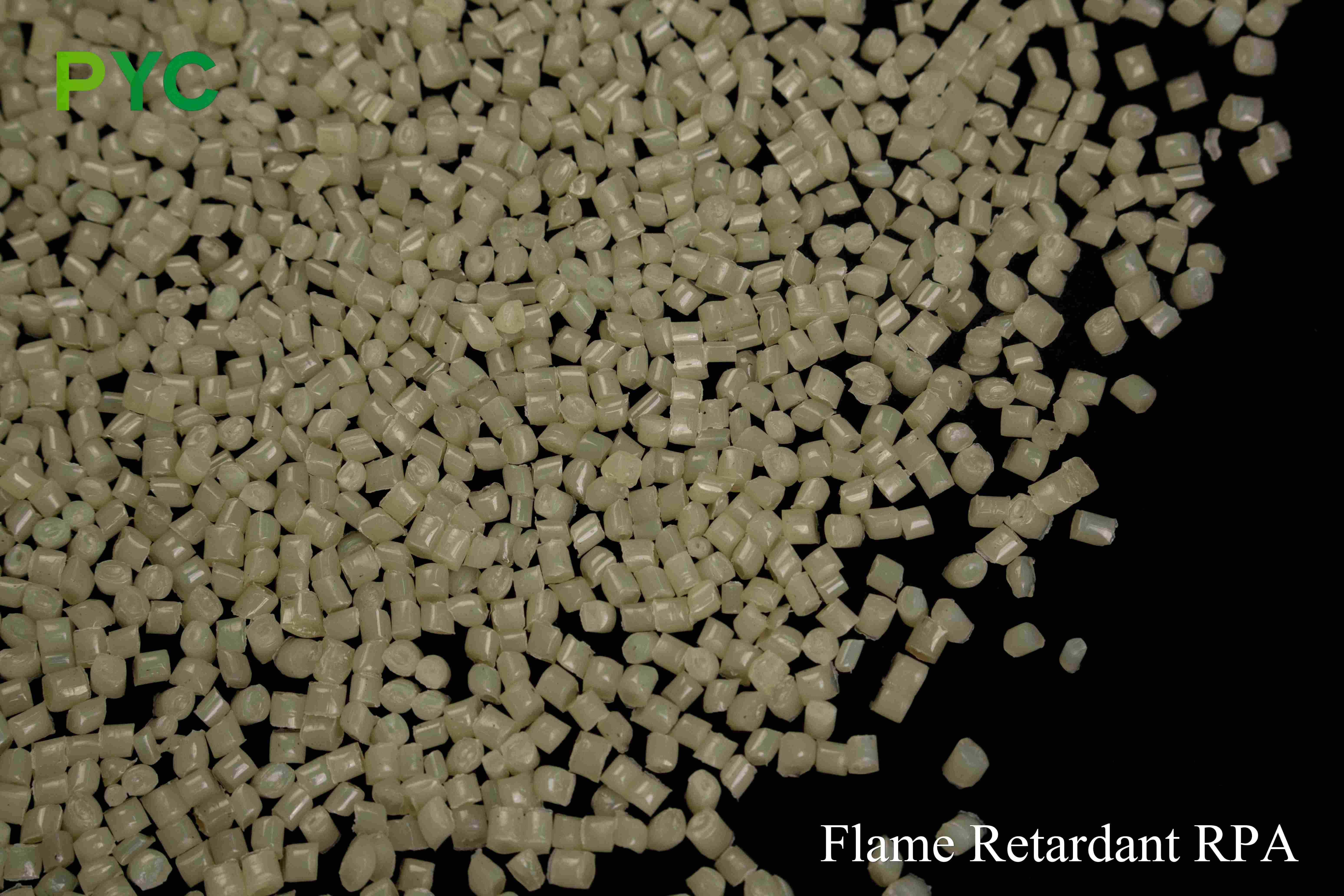

Flame Retardant RPA

Product Highlights

High quality ingredients

Flame Retardant RPA (Flame Retardant Recycled Polyester) uses a high purity recycled polyester raw material, ensuring that it comes from a single source supplier, has undergone rigorous screening and fine treatment. Key recycled sources include:

Waste textiles: including used clothing, cloth, textile waste, etc., these recycled polyesters are derived from high-quality textiles that have been cleaned, sorted and treated to ensure low impurity content and high purity, suitable for flame retardant applications.

Plastic bottles and containers: mainly from PET bottles, beverage containers and other polyester products, the recycling process includes cleaning, de-labeling, melting granulation, etc., to ensure the high purity and stability of polyester materials, while improving the flame retardant performance.

Industrial waste: including the waste polyester materials produced in the industrial production process, such as plastic sheets, film materials, packaging materials, etc., these wastes are screened and purified to ensure that the material has a low impurity content and good flame retardant effect.

All recycled raw materials are from reliable suppliers, after strict screening and treatment, to ensure that the material has good flame retardant performance, high purity and consistency, widely used in textiles, packaging materials, electrical equipment, building materials and other fields.

Strict quality control

During production, Flame Retardant RPA performs comprehensive quality testing, including melting index, impact strength and flame retardant performance testing, to ensure that every batch of products comply with UL94 V0 flame retardant standards. The products also pass REACH and RoHS environmental certification to ensure compliance with environmental requirements.

High efficient flame retardant performance, higher safety

FR RPA uses advanced flame retardant formulations up to UL 94 V0, V1 or V2 grades, ensuring that the material can quickly inhibit combustion and reduce the risk of flame propagation when exposed to high temperatures or open flames. Compared with ordinary PA (polyamide/nylon), FR RPA provides higher fire protection performance, meets the safety requirements of electronic appliances, automotive parts and other industries, and is suitable for application scenarios with strict requirements for flame retardancy.

Both high strength and heat resistance, stable and reliable

FR RPA retains the high mechanical strength of nylon material, while ensuring the flame retardant properties, it still has excellent impact resistance and fatigue resistance. Its excellent heat resistance can maintain stability in a long-term high temperature environment, ensuring that the material will not be deformed or aging due to temperature changes. This characteristic makes it more reliable in long-term use in automotive, electronics, industrial equipment and other industries.

Sustainable and environmentally friendly, it is produced from recycled materials

FR RPA is made from Recycled nylon (Recycled PA), which is in line with the concept of sustainable development. Through an efficient recycling process, the material is able to effectively reduce carbon emissions and reduce the consumption of native resources, while still maintaining excellent mechanical properties. Compared to traditional flame-retardant nylon, FR RPA is more environmentally friendly and complies with international environmental regulations such as RoHS and REACH, providing enterprises with a sustainable material choice.

Strong processing adaptability, to meet a variety of process needs

FR RPA has good fluidity and processing stability, suitable for injection molding, extrusion, blow molding and other molding processes, can easily meet the production needs of complex structural parts. At the same time, its low water absorption formula can reduce the problem of dimensional change caused by moisture absorption, improve the stability and service life of the product. Whether it is a high-precision electronic component or a durable automotive part, FR RPA provides reliable processing performance and excellent molding results.

Product Details

Product Description

Flame Retardant RPA (FR RPA) is a high-performance recycled polyamide (nylon), by adding efficient flame retardants, improve the fire resistance grade of the material, while maintaining the original high mechanical strength, heat resistance and chemical resistance of nylon. The material not only has the light and high strength characteristics of traditional PA, but also has both flame retardant and environmental protection properties, making it an ideal choice for electronic appliances, auto parts, industrial equipment, building materials and other fields. FR RPA is available in a halogen-free flame retardant version that meets environmental regulatory requirements and maintains excellent performance under high temperature, high humidity and high load environments.

Main application areas

Electronic appliances: widely used in electrical components, connectors, sockets, electronic equipment shells, power adapters and other components, to ensure that electronic products have higher safety under high temperature or short circuit, reduce the risk of fire.

Automotive industry: Suitable for automotive engine compartment components, lamp brackets, fuse boxes, battery components and other structural parts working under high temperature environment, to ensure that the material still has good mechanical properties under long-term high temperature load.

Industrial equipment: Used in mechanical engineering and automation equipment for the manufacture of high temperature resistance, wear resistance, flame retardant parts, such as gear, bearing seat, motor housing, etc., to improve equipment safety and durability.

Building materials: cable sheathing, switch panel, electrical box and other components applied to high-rise buildings to improve the fire resistance inside the building and reduce fire hazards.

Technical parameters (examples)

Typical values for project units

Density g/cm³ 1215

Melting index (MFI) g/10min812 (250°C, 16kg)

Tensile strength MPa 6080

Bending modulus MPa 22002800

Notch impact strength kJ/m² ≥10

Thermal deformation temperature (HDT) °C 120140

Water absorption (24h) % 0.50

Flame retardant rating (UL 94) V0 / V1 / V2

Production and Processing

FR RPA has excellent processing adaptability, suitable for injection molding, extrusion, blow molding process, can meet the production needs of high-precision structural parts. Its low hygroscopic formula effectively reduces the common problem of water absorption and expansion of nylon materials, and improves the dimensional stability and long-term durability of the product. During injection molding, FR RPA has a wide processing temperature range (230°C 280° C), which can meet the process needs of different equipment while maintaining excellent molding results. For applications requiring high toughness, wear resistance and heat resistance, the FR RPA can also be Reinforced with glass fiber (GF) to further enhance the mechanical properties.

Quality & Certification

FR RPA is produced and tested in strict accordance with international standards, products comply with UL 94 V0, RoHS, REACH and other environmental protection and flame retardant standards, and can provide halogen-free versions to ensure that the material will not release harmful substances during use. All batches of products have undergone strict combustion test, impact test, thermal stability test, humidity and heat resistance test, etc., to ensure the safety and stability of the final product.