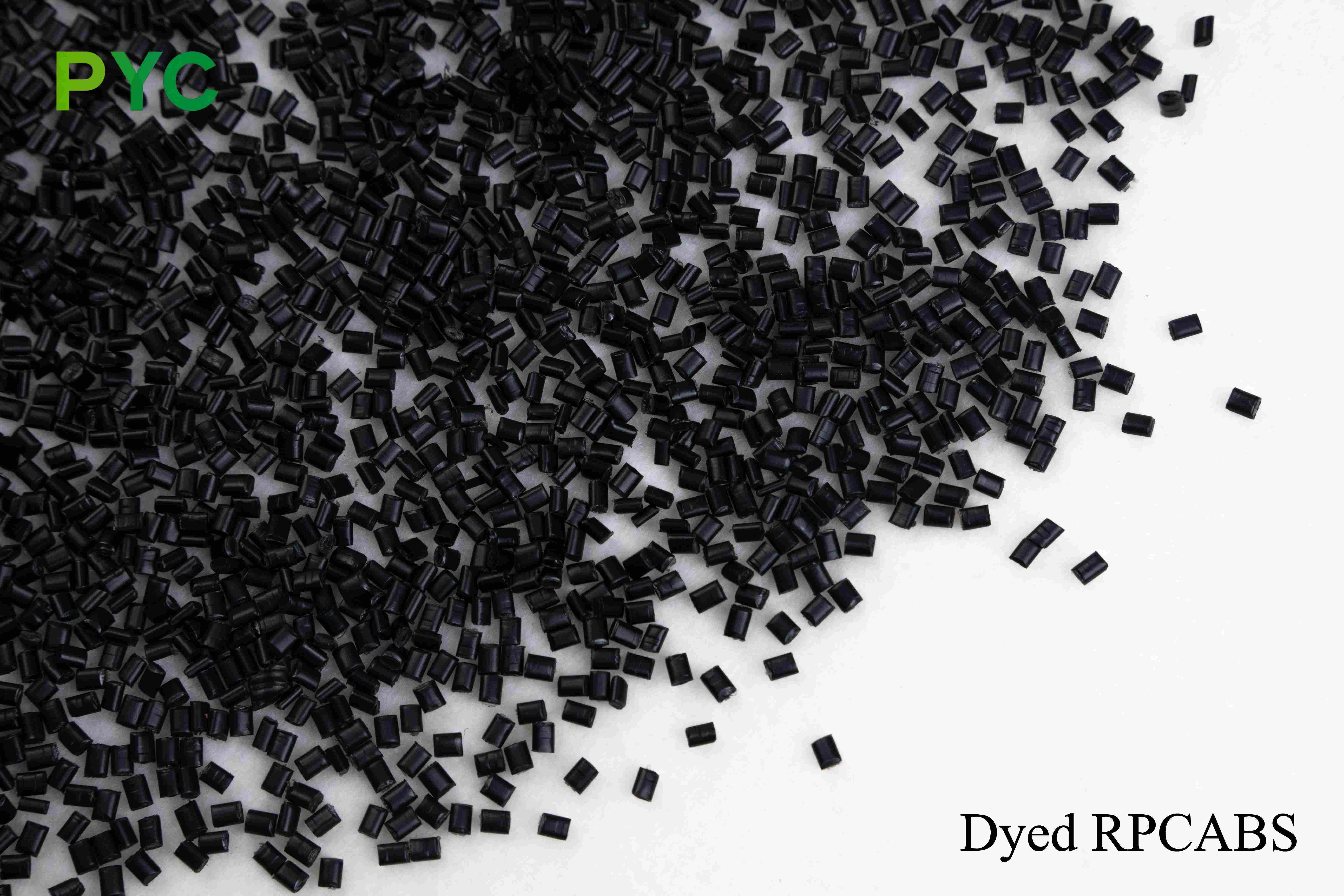

Dyed RPC/ABS

Product Highlights

High quality ingredients

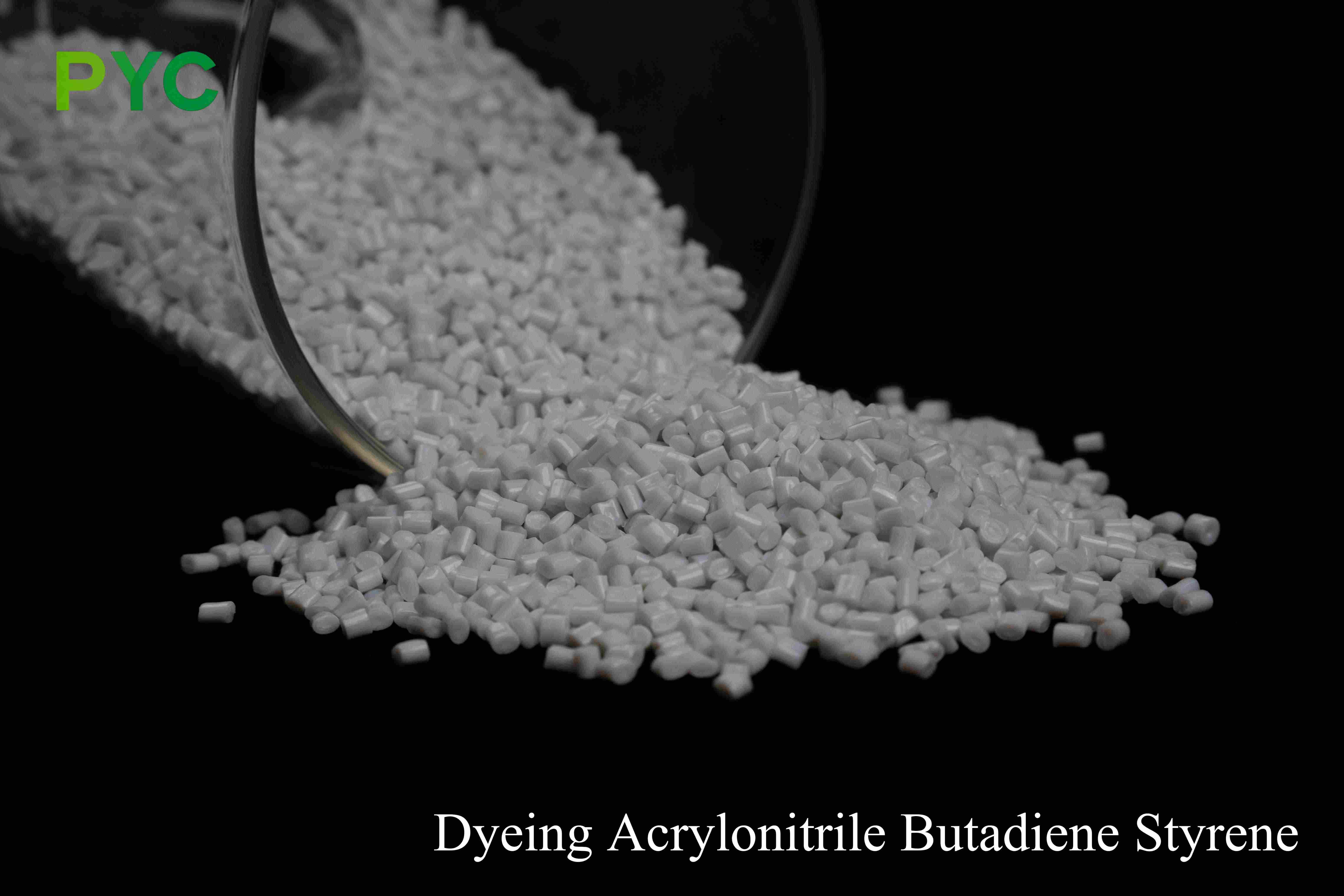

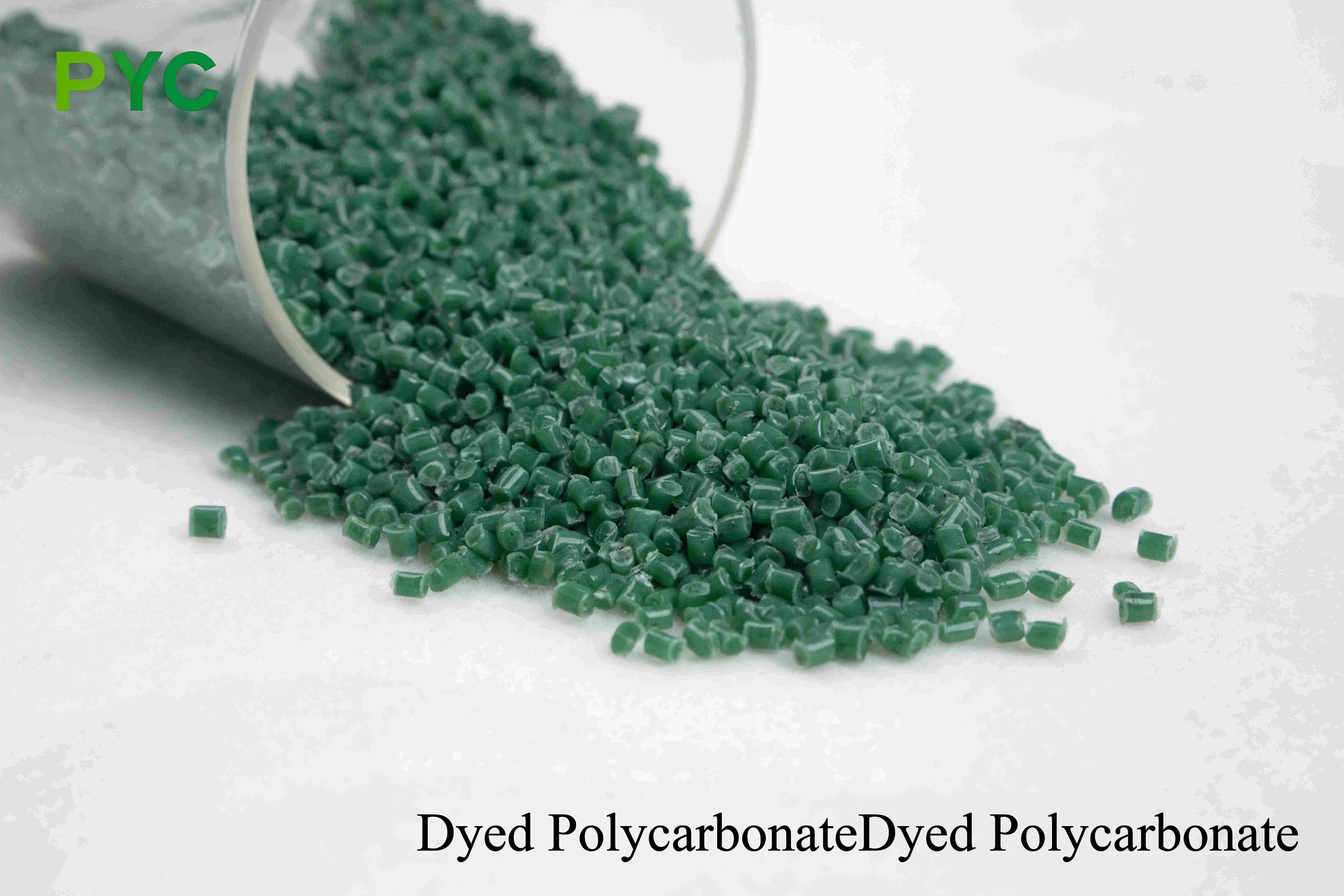

Dyed RPC/ABS (Dyed Recycled Polycarbonate/acrylonitrile butadiene styrene alloy) Dyed RPC and acrylonitrile butadiene styrene (ABS) raw materials were recovered with high purity, ensuring a single source and from strictly selected upstream suppliers. Key sources of recycling include:

Electronic equipment shell: including mobile phone shell, tablet computer shell, laptop computer shell, etc., the recycled RPC and ABS raw materials are carefully screened to ensure excellent dyeing effect and high stability.

Home appliance housings: including TV housings, refrigerator housings, air conditioning housings, etc. The recycled RPC and ABS raw materials have extremely low impurity content, ensuring the strength and stability of the products after dyeing.

Automotive interior parts: including vehicle display frame, instrument panel, interior trim parts, etc. The recycled RPC and ABS alloy raw materials have been strictly screened to ensure their excellent dyeing performance and high impact resistance.

All raw materials are carefully screened to reduce impurities and ensure the consistency of the final product in stability, strength and excellent dyeing effect, which meets the requirements of high-end products.

Strict quality control

During the production process, Dyed RPC/ABS passed strict quality control to ensure that the color is uniform, dyed and not easily faded. Each batch of materials has been tested for chromatic aberration, mechanical properties and weatherability, ensuring that the products still maintain their outstanding physical properties and visual effects during long-term use. Meet REACH and RoHS environmental certification to ensure its environmental compliance, suitable for a variety of demanding industry applications.

Excellent color stability

Dyed RPC/ABS uses advanced dyeing techniques to ensure that the colors remain bright and do not fade easily during long-term use. The color of the material remained stable even after exposure to strong ultraviolet light, meeting applications that require higher beauty and durability, especially for home decor, toys, etc.

Enhanced impact resistance and strength

Dyed RPC/ABS combines the advantages of polypropylene (RPC) and acrylonitrile butadiene styrene (ABS) for excellent impact resistance and strength. The material retains its stability and shape under high loads, making it ideal for use in products requiring high strength and durability, such as electronic housings, auto parts, etc.

Good processability and formability

Dyed RPC/ABS has excellent processing properties and can be dyed efficiently through various methods such as injection molding, extrusion, etc., to adapt to the design needs of different products. Dyed RPC/ABS can provide high-precision processing effects, whether for complex shapes or fine details, Dyed RPC/ABS is an ideal choice for the manufacture of precision products.

Environmentally friendly and recyclable

Dyed RPC/ABS uses recycled raw materials to comply with environmental standards and has a lower carbon footprint. At the end of the product's life cycle, the materials can be recycled again, in line with the growing global interest in green production and circular economy, contributing to sustainable development.

Dyed RPC/ABS product introduction

Dyed RPC/ABS is a composite material that combined polypropylene (RPC) with acrylonitrile butadiene styrene (ABS) for excellent color stability, impact resistance and processing properties. Through advanced dyeing techniques, Dyed RPC/ABS was able to maintain bright colors and long-term appearance stability, dyed RPC/ABS is suitable for applications requiring beauty and high durability, such as home appliance casings, toys, auto parts and household articles.

Compared with the traditional single material, Dyed RPC/ABS is able to bring out the advantages of both materials by combining RPC and ABS. Its impact resistance was improved by about 40% compared with ordinary RPC, and the material was able to maintain a stable form and strength even under high load or impact environments. Its excellent heat resistance, oxidation resistance and weather resistance enable it to provide reliable performance in a variety of environments, especially suitable for high-strength, durable product design needs.

In addition, Dyed RPC/ABS has good workability and can be formed efficiently through common injection molding and extrusion processes, adapting to production needs with different shapes and accuracy requirements. This enabled it to demonstrate good adaptability in complex product designs, meeting the market demand for high-precision and high-quality products.

In terms of environmental protection, Dyed RPC/ABS used recycled raw materials that meet international environmental standards and minimized negative impact on the environment during the production process. Through recycling materials, Dyed RPC/ABS has achieved maximum utilization of resources during the production process, helping to promote circular economy and sustainable development.

With its outstanding performance, Dyed RPC/ABS has become an ideal choice for all kinds of high-end products. Whether targeted at the household consumer market or industrial applications, this material is able to provide ideal performance and long-lasting use value, meeting the needs of different customers, and promoting the dual goals of innovation and environmental protection.