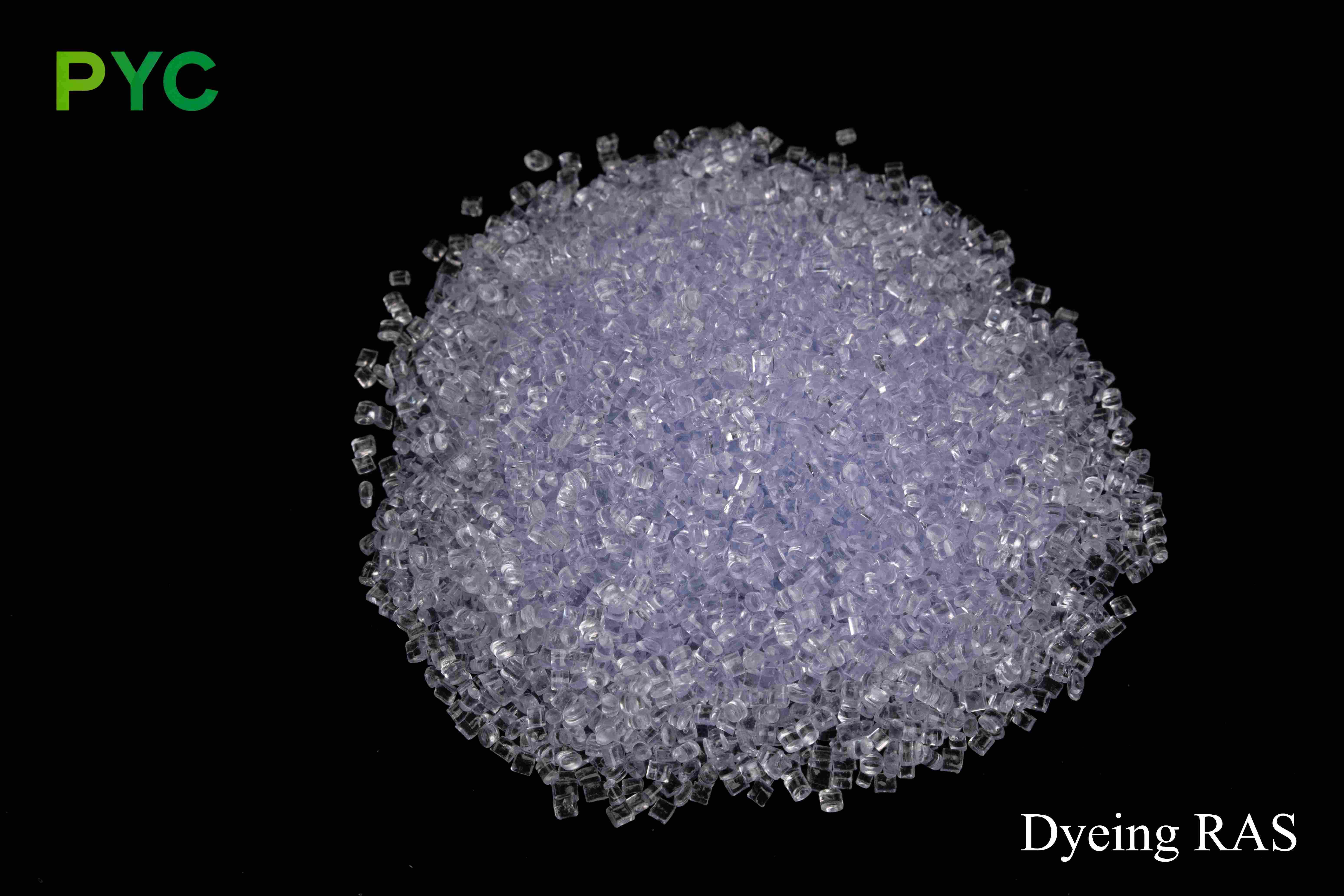

Dyeing RAS

Product Highlights

High quality ingredients

Dyeing Recycled polystyrene (Dyeing Recycled Polystyrene) uses high quality recycled polystyrene (RAS) as a raw material and is sourced from highly screened and reliable suppliers. Key recycled sources include:

Electronic products housing: including television, audio equipment, computer housing, etc., recycled polystyrene (RAS) material through strict screening and precision sorting to ensure that it is free of impurities, retain excellent physical properties, suitable for dyeing and other processing applications.

Packaging materials: including plastic packaging, CD box, etc., the recycled materials are carefully screened to ensure a very low impurity content, to ensure the consistency of dyeing effect and surface quality.

Home appliance shell: including refrigerator, washing machine, air conditioning and other home appliance shell, these parts of the recycled polystyrene after purification treatment to ensure its color uniformity and excellent processing performance.

Industrial components: including electrical equipment housings, advertising panels, etc., recycled polystyrene (RAS) materials are rigorously screened and treated to ensure stable physical properties and high staining consistency.

All raw materials are precision separated to ensure no impurities, to maximize the retention of the excellent performance of polystyrene, in line with environmental standards, to ensure that the final product has high quality and consistency, widely used in electronics, packaging, home appliances and industrial fields.

Strict quality control

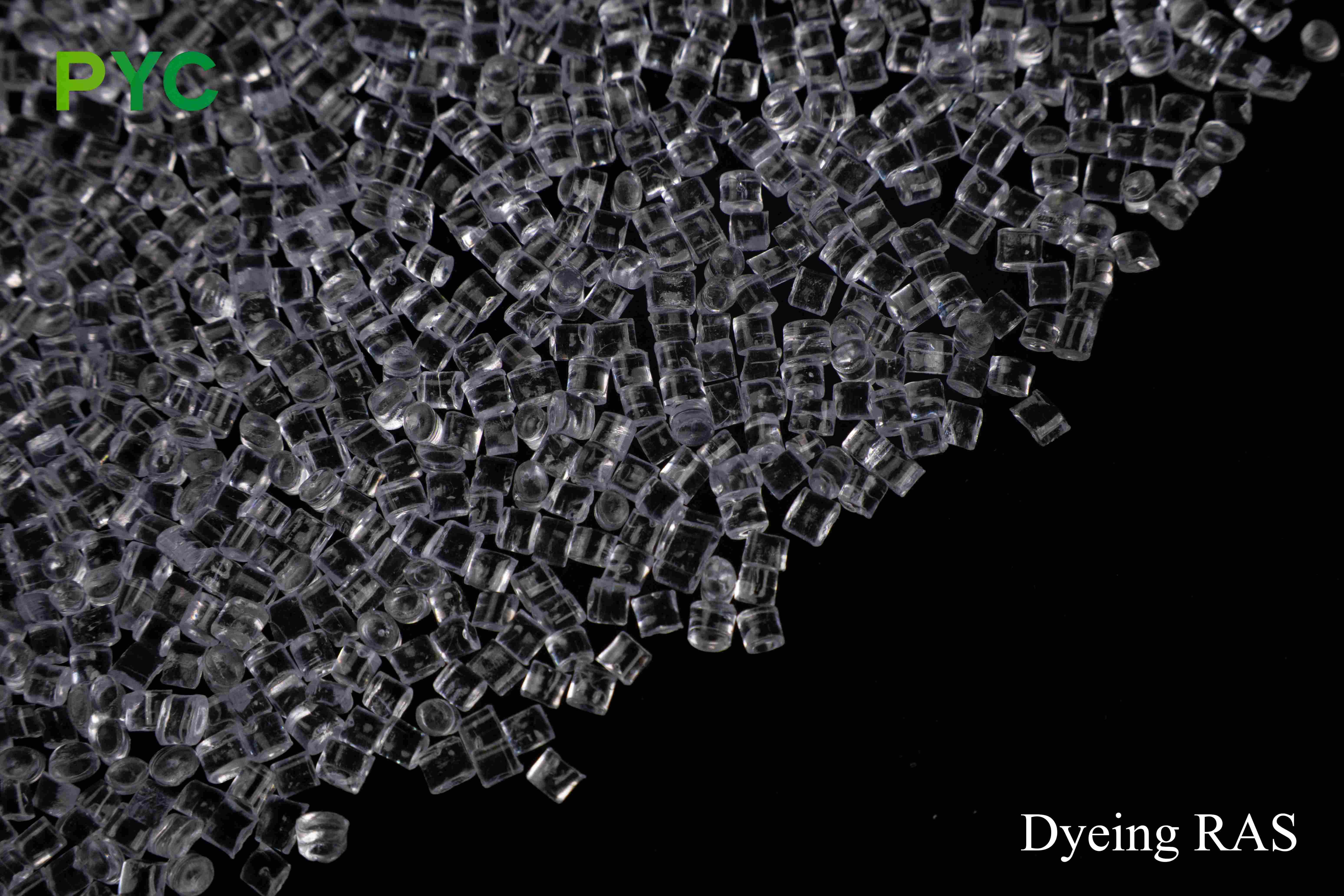

Dyeing RAS strictly follows the quality management system in the production process, and carries out a number of quality tests, such as tensile strength, impact testing and UV resistance, etc., to ensure that the product maintains stable performance under various use environments. The products comply with REACH and RoHS environmental protection certification to ensure that the material meets the environmental protection standards and the quality is fully guaranteed.

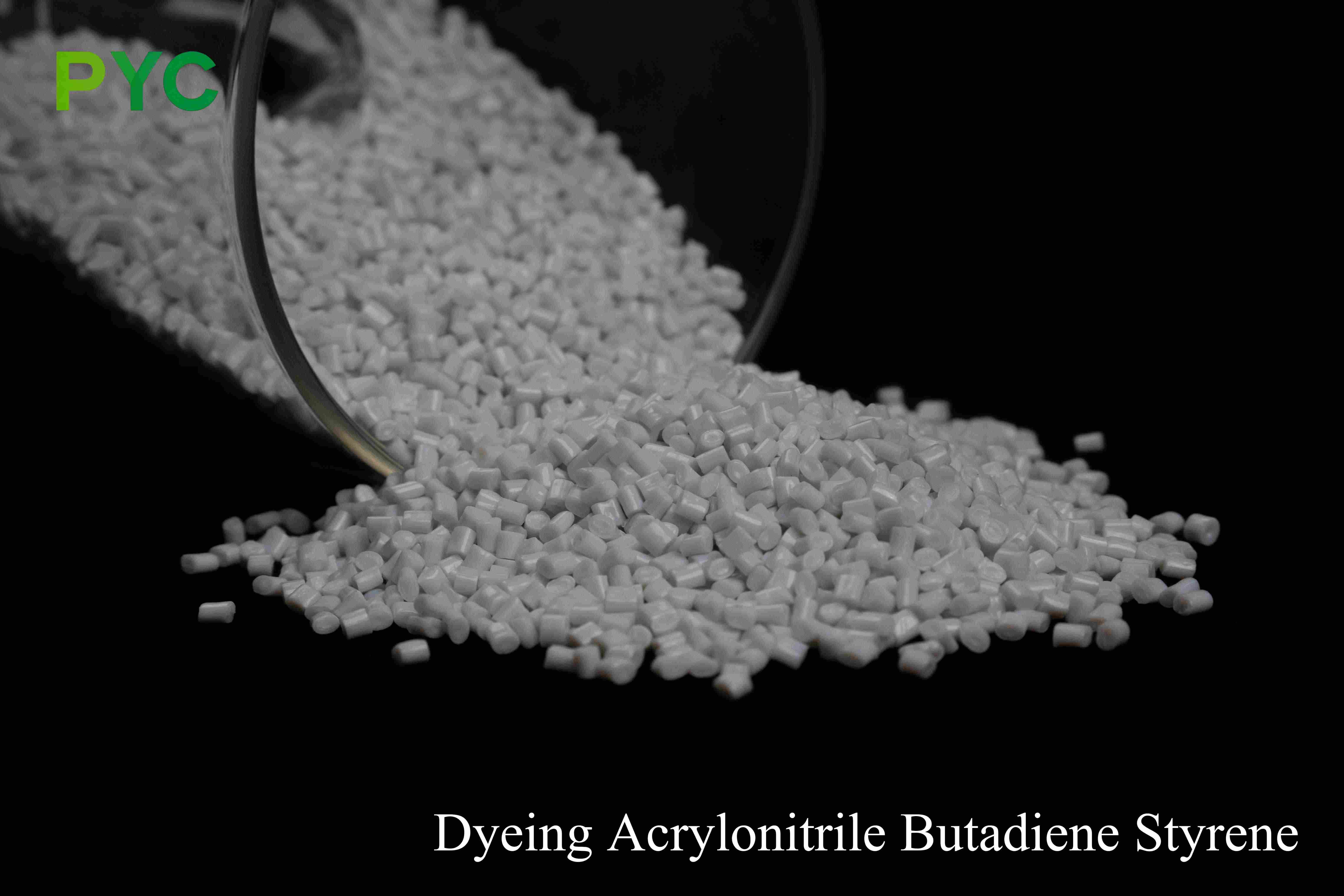

High quality dyeing - Using advanced coloring process, the color of recycled ABS (RAS) material is uniform and stable, suitable for high-end appearance needs.

Environmentally sustainable -- Based on recycled ABS, it reduces the consumption of primary plastics and complies with global environmental regulations (REACH, RoHS).

Excellent mechanical properties - Combined with the high impact strength of ABS, good fluidity and dimensional stability, suitable for a variety of processing methods.

Wide application - can be used in consumer electronics, home appliances, auto parts and other industries, support a variety of color customization, to meet the needs of different brands.

Efficient supply chain - Relying on modern production system to ensure fast delivery, to meet the global customer's mass procurement needs.

Product Details

Technical process and quality assurance

Dyeing RAS (Dyed RAS) is a professionally dyed, recycled ABS material with high dispersion dyes and precision coloring techniques to ensure color consistency and durability. Compared to regular ABS, recycled ABS has superior environmental properties, while Dyeing RAS further enhances its aesthetic appeal, making it suitable for products with high aesthetic requirements. All dyed RAS particles are strictly screened to ensure uniform color from batch to batch, without chromatic aberration issues, and meet environmental certification standards such as REACH and RoHS.

Application scenarios and customer cases

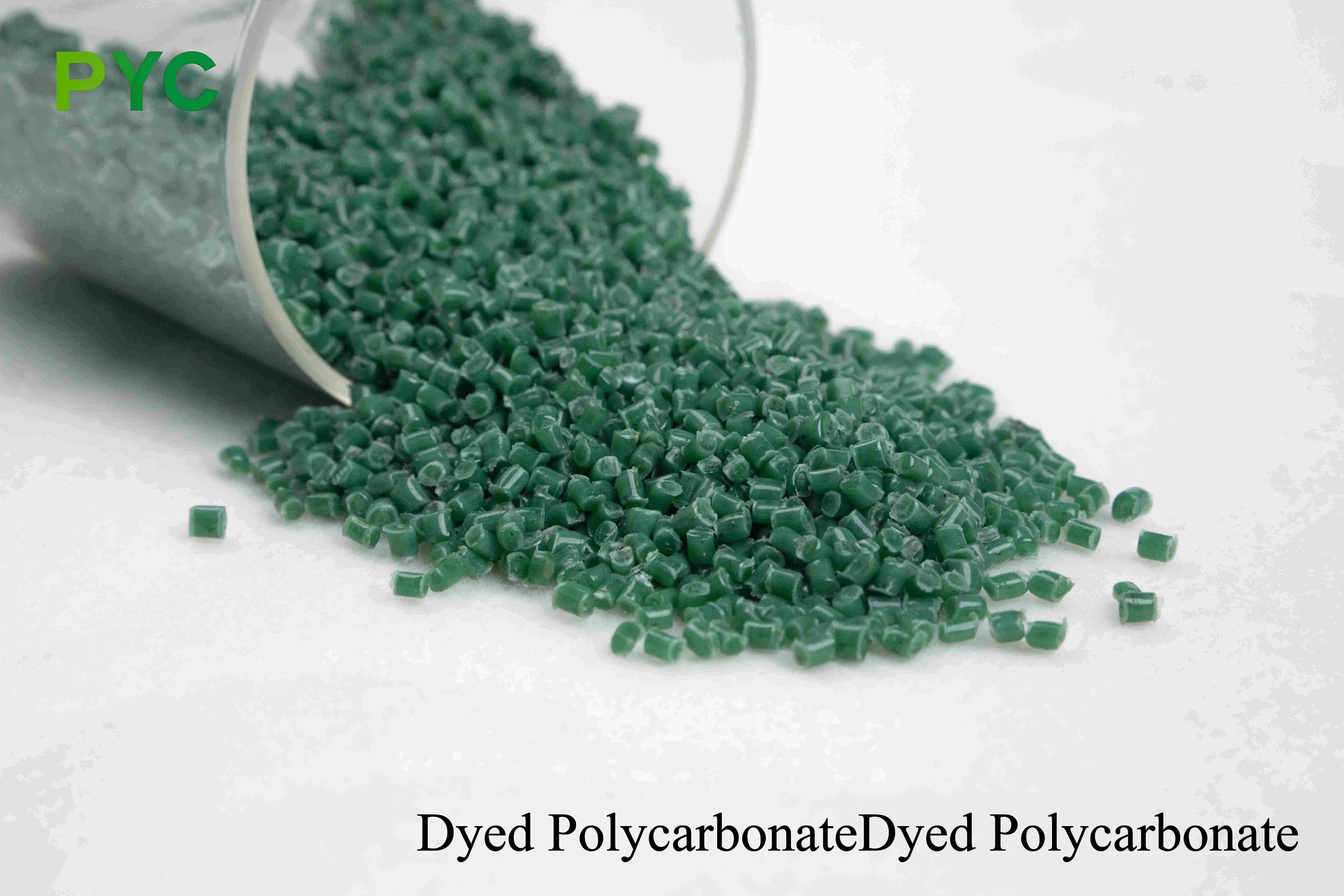

Dyeing RAS is primarily used in industries that place equal emphasis on appearance and performance, including:

Electronic appliances: such as TV housings, audio panels, household appliance accessories, etc., to ensure long-term use without fading and discoloration.

Automotive industry: Used in car interior parts, such as instrument panel, door panel, control panel, etc., to provide beautiful and wear-resistant solutions.

Consumer goods: such as luggage, toys, smart home products, etc., can be customized according to the brand's needs, enhance the visual appeal of the product.

At present, Dyeing RAS has been adopted by a number of well-known brands to provide it with a customized color scheme to help enhance market competitiveness.

Production strength and sustainable development

The company has intelligent dyeing production line, through the automatic color distribution system and high temperature extrusion dyeing process, to ensure the stability of dyeing and high weather resistance. With an annual production capacity of 50,000 tons, the company can meet the needs of large-scale orders. At the same time, the company is committed to sustainable development, using recycled ABS as raw materials to reduce carbon emissions by 30%, and establishing a recycling system to improve resource utilization.

Innovative research and development and future planning

In the future, the company will continue to optimize the color fastness, weather resistance and mechanical properties of Dyeing RAS materials, and launch functional dyeing RAS products such as anti-UV type and flame retardant type to meet the higher demand of electronics, automotive, medical and other industries. In addition, the company plans to expand the intelligent color matching center, enhance the ability of personalized customization, to provide more accurate color solutions for customers around the world.