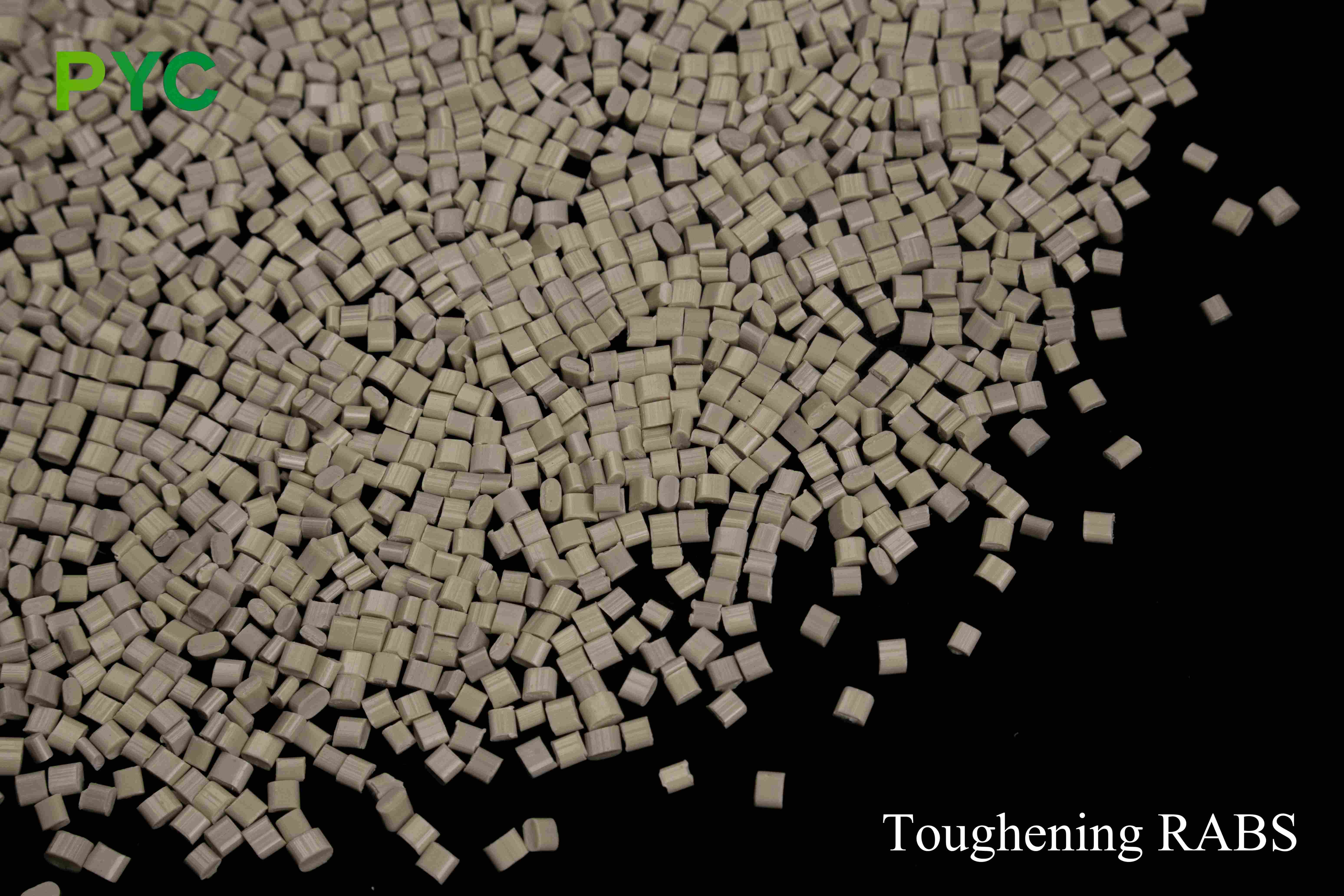

Toughening RABS

Product Highlights:

Toughening RABS, a high-quality recycled ingredient

Toughening RABS is a single-source, rigorously screened recycled acrylonitrile butadiene styrene (RABS) from industrial injection molding scraps, extrusion waste and unused molded parts. All raw materials are sourced from stable upstream suppliers and are screened and purified to ensure the purity and stability of the material, while guaranteeing good impact resistance and mechanical properties for applications requiring high toughness and impact resistance. Selected recycling sources

Industrial injection moulding scraps: Derived from acrylonitrile butadiene styrene (RABS) injection moulding scraps produced during the manufacturing of automotive parts. Through fine screening, surface impurities are removed, these scraps are not actually used, contain very few impurities, and ensure the high purity of the material.

Extrusion waste: includes RABS extrusion waste from the home appliance housing production process. These scraps are rigorously screened and inks, coatings and other contaminants removed, ensuring the stability and good physical properties of the material after recycling.

Unused molded parts: RABS molded parts, such as housings or parts, that are derived from unused parts in the manufacturing of consumer electronics. These molded parts are unused, of high material purity, and have been treated to maintain excellent impact resistance and mechanical properties.

Through careful screening and cleaning of these source materials, Toughening RABS delivers high impact resistance and stable mechanical properties for applications where material requirements are stringent, such as automotive exterior parts and consumer electronics housings.

Significantly improve impact resistance and durability:

With advanced Toughening technology, Toughening RABS offers higher impact resistance than conventional recycled ABS materials, making it ideal for applications in extreme environments. Compared to standard ABS, Toughening RABS offers approximately 30% better impact resistance. The material is able to maintain structural integrity and reduce cracking and breakage even in the case of high load impact.

Greater processing adaptability:

Toughening RABS has been optimized and modified to retain good processing properties. Whether in injection molding, extrusion or other common processing processes, Toughening RABS exhibits excellent flow and formability. This makes the production process more efficient and stable, reduces scrap rates and improves production efficiency, making it suitable for mass production applications.

Environmentally friendly materials for sustainable development:

Toughening RABS, a toughened version of recycled ABS, emphasizes resource recycling and environmental performance. Its production process complies with global environmental standards and helps reduce the accumulation of plastic waste. By using Toughening RABS, companies can not only improve product quality, but also respond to the market demand for sustainable development and green manufacturing.

Multi-industry applications, adaptable:

Toughening RABS is used in a wide range of industries and is especially suitable for products requiring high strength and durability. Whether it's exterior trim for the automotive sector, electrical housings for the home appliance industry, or housing components for consumer electronics, Toughening RABS delivers rugged performance while remaining aesthetically pleasing.

Product Details:

Fields of Application:

Toughening RABS is widely used in a variety of industries, especially those with high impact resistance requirements. In the automotive industry, it is widely used in components such as body bumpers, upholstery and lights to provide enhanced safety and stability. In the home appliance industry, Toughening RABS are used to cover appliances such as televisions, refrigerators and washing machines to prevent wear and tear during long-term use. In the consumer electronics industry, Toughening Rabs is used as a housing component for devices such as smartphones, televisions and stereos to help improve their durability and long-term stability.

Success stories:

Toughening RABS has been used in a number of demanding projects. For example, Toughening RABS is used by some of the world's leading automotive brands for interior trim and bumpers, which not only enhances the aesthetics of the interior, but also provides significant impact resistance in crash tests. Another well-known home appliance brand uses Toughening RABS in the manufacture of refrigerator casings, which ensure the stability of the product during transportation and use through excellent impact resistance and high toughness, and enhance the customer experience.

Technology and Innovation:

Toughening RABS 'toughening technology is based on recycled ABS with high-performance tougheners and modifiers that have been tested and adjusted to ensure excellent impact resistance in a variety of operating environments. Toughening RABS maintains stable physical properties, especially under low or high temperature conditions. In addition, the research and development team continuously optimizes the processing properties of the material to ensure the high efficiency and stability of Toughening RABS in production.

Production and Quality management:

Toughening RABS is manufactured in accordance with strict quality management standards, from raw material procurement to the final product delivery, every step is carefully tested. The company has advanced production equipment to ensure that the quality of each batch of Toughening RABs meets international standards. In addition, Toughening RABS has a short production cycle and flexible supply capacity to meet customers' demand for high-volume production and provide customized services.

Toughening RABS is an indispensable key material in many industries due to its excellent impact resistance, good processing adaptability and environmental benefits. It not only provides a reliable performance guarantee, but also promotes the advancement of enterprises in terms of sustainable development.