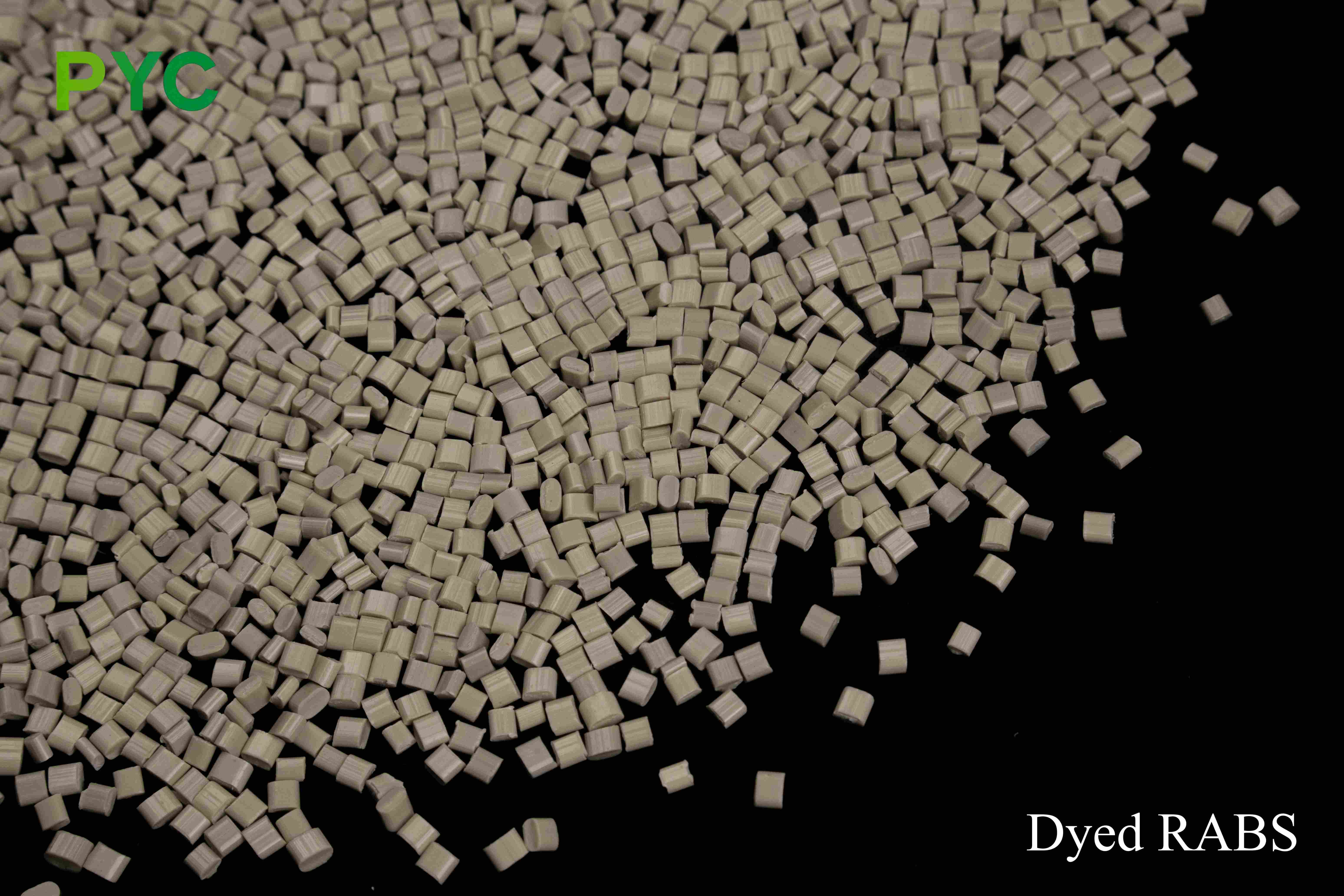

Dyed RABS

Product highlights:

High quality recycled raw materials

Dyed RABS uses sole-sourced, rigorously selected recovered acrylonitrile butadiene styrene (RABS) raw materials derived mainly from industrial injection molding scraps, extrusion waste, and unused molded parts. All raw materials are sourced from reliable upstream suppliers and carefully screened to ensure the stability and mechanical properties of the material, while reducing the impact of impurities on the quality of the finished product and ensuring color uniformity and physical properties of the final product.

Selected recycling source

Industrial injection molding scraps: Derived from injection molding scraps produced during the RABS production process, most of these wastes are unused, and after screening and cleaning treatment, the content of impurities is low, ensuring high quality recycled raw materials.

Extrusion waste: Includes waste generated during the extrusion of RABS, which has been rigorously screened to ensure the purity of the material and low impurity content, making it suitable for use in the production of Dyed RABS with high performance.

Unused molded parts: Derived from RABS parts not used during the molding process, the material is unused and contains fewer impurities, which have been screened and treated to maintain high purity and stability.

Through rigorous screening and processing, Dyed RABS was able to ensure high stability, consistency and excellent mechanical properties of the raw materials, as well as dyed uniformity of color, meeting requirements for applications of high-quality appearance and performance.

Strict quality control

Dyed RABS was dyed during the production for melt index (MFI), impact strength and color uniformity detection to ensure excellent processing stability and lasting color presentation. Its strong weatherability and ability to remain brightly colored under ultraviolet radiation have made it widely used in home appliance casings, automotive interiors, consumer electronics and other industries requiring aesthetic dyed.

Rich color selection, enhance visual effect:

Dyed RABS 'dyeing techniques ensure long-lasting and vibrant colors of the products. Compared with traditional undyed ABS materials, Dyed RABS retains its distinctive color despite prolonged exposure to sunlight or other environmental factors, and is widely used in products requiring an aesthetically pleasing appearance. Whether it is electronic casings, home appliance accessories, or automotive interiors, Dyed RABS brings consumers more possibilities for color choices and personalized customization.

Enhanced physical properties to withstand greater load:

Dyed RABS improved impact resistance by 30% compared with ordinary ABS. Dyed RABS can still provide stable protection even in environments of high loads and violent collisions, Dyed RABS is not prone to cracking or damage. This advantage has enabled dyed rabs to provide higher durability and greater reliability in applications in automotive, electronics and home appliances.

Environmental protection and resource recycling:

Dyed RABS, made entirely from recycled ABS plastic, dyed rabs meets environmental standards and helps to reduce plastic waste. Through this sustainability approach, Dyed RABS helped enterprises reduce production costs while dyed rabs protected the environment. Dyed RABS chosen to contribute to dyed rabs' circular economy while improving the environmental image of dyed rabs.

Excellent processing adaptability, improved production efficiency:

Dyed RABS performed excellently in injection molding, extrusion and other processing processes, with good fluidity and processing stability. Due to its high-quality processing techniques for recycled materials, Dyed RABS ensures dimensional stability and processing accuracy of products during the production process, helping enterprises improve production efficiency and reduce scrap rate.

Product details:

Wide range of applications:

Dyed RABS 'strength and durability make it suitable for use in multiple industry sectors. Specifically, it is widely used in the automotive industry, especially parts such as interior trim parts, seats, dashboards and lights, which not only enhance the interior design of vehicles, but also ensure the safety and stability of long-term use. In the field of consumer electronics, Dyed RABS is often used in the covers of smartphones, stereos, televisions and other consumer electronic products, adding to the visual appeal of the products. In the home appliance industry, Dyed RABS was used in the shells of electrical appliances such as refrigerators and washing machines, which were dyed to withstand friction and collisions during daily use and ensure appearance and structural integrity during long-term use.

Practical cooperation cases:

During the cooperation of an automobile brand, Dyed RABS was chosen for the production of automotive interior parts. After rigorous quality inspection, Dyed RABS improved the beauty of the interiors while maintaining the high strength and impact resistance of the parts, meeting international safety standards. In the consumer electronics industry, Dyed RABS has been successfully applied in the production of shells of several globally recognized brands, bringing a unique appearance to products and meeting durability requirements.

Research & Development & Technology:

Dyed RABS 'dyeing process used polymer pigment formulation and, through precise control of dye concentration, ensured that the dyed effect was uniform without affecting the mechanical properties of the material itself. The team also optimized the compatibility of the dye with the material so that it maintained a stable color performance over long periods of use, while not affecting the heat and weather resistance of the material. Dyed RABS 'successful research and development and innovation have made it widely recognized in multiple demanding industrial applications.

Production and Quality Assurance:

The company has advanced production equipment and strict quality control system, from raw material recycling to dyeing process every step is strictly checked. Through efficient production management, Dyed RABS 'production cycle is short and its quality is stable, meeting the needs of mass production and customization. We also maintain sufficient inventory to ensure that customers can obtain the products they need quickly and reduce production waiting times.

Dyed RABS, as a high-performance material with aesthetically pleasing colors, excellent physical properties and environmental sustainability, has become a preferred material for various industries. It not only improves the beauty of products and market competitiveness, but also conforms to the trend of green production and provides more advantageous solutions for enterprises.