RPS

Product highlights:

High quality recycled raw materials

RPS (Recycled Polystyrene) uses a single source, rigorously screened industrial recycled PS raw material, mainly from the following specific recycling channels:

Electronic product housing: PS housing derived from waste electronic equipment, such as televisions, computers, printers, etc. These materials are disassembled, cleaned and sorted to ensure high purity of raw materials and excellent mechanical properties.

Packaging sheet: mainly includes discarded PS foam board, protective packaging, etc., widely used in household appliances, instrument packaging. After the removal of impurities, crushing and reshaping, to ensure the low impurity content of the material and stable processing performance.

Disc cases: Using discarded CD/DVD disc cases, these materials are usually made of high purity PS, sorted and finely cleaned to provide excellent rigidity and chemical resistance.

Injection molding scraps: from the corner waste in the production process of PS products, such as the injection molding residue of home appliance shell, toys, stationery supplies. These materials are not used, the quality is stable, and after strict screening and purification, it can ensure the excellent mechanical properties of recycled materials.

All raw materials have been carefully screened and purified to ensure low impurity content, giving RPS excellent rigidity, chemical resistance and processing stability, which is suitable for home appliance shell, packaging materials, building decoration panels and other fields.

Strict quality control

RPS is tested by melt index (MFI), impact strength and thermal stability in the production process to ensure the reliability of the material in processing and use. Its high hardness, good fluidity and excellent dimensional stability make it widely used in electronic and electrical shell, packaging, building materials and modified masterbatch and other fields.

Environmental protection and recycling, reduce plastic waste:

RPS is produced by recycling polystyrene waste, minimizing the environmental impact of plastic waste in the production process. The use of recycling technology not only reduces the waste of resources, but also effectively reduces the carbon footprint, in line with the current high standards for environmental protection and sustainable development.

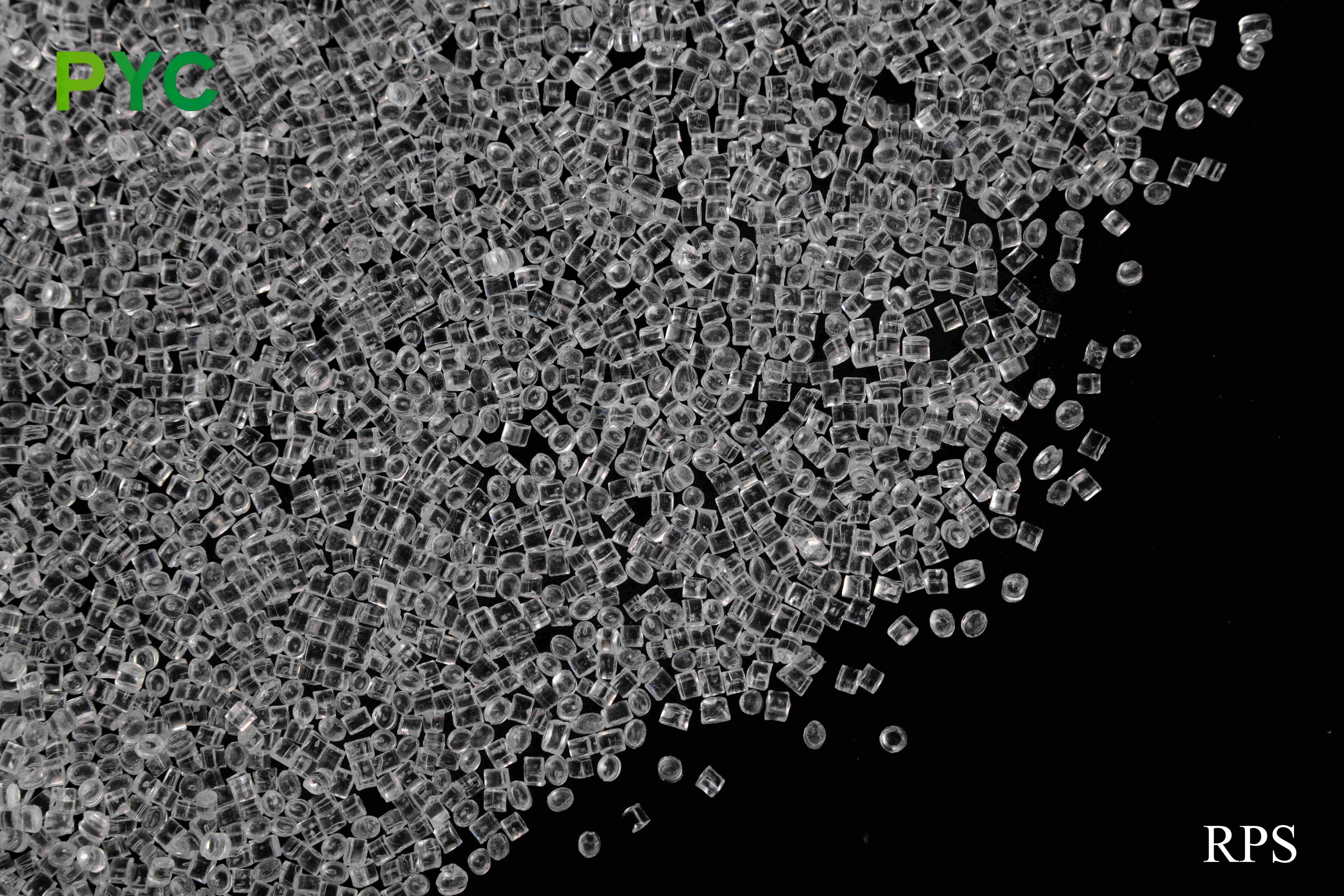

Excellent rigidity and transparency:

RPS retains the original characteristics of polystyrene with high rigidity and transparency, which can meet the requirements of high transparency and good rigidity, such as packaging materials and home appliance housings. It ensures good physical properties while providing a high quality appearance.

Good workability:

The processing properties of RPS are similar to those of native polystyrene and are suitable for a variety of molding processes such as injection molding, extrusion and thermoforming.

Whether it is to produce packaging containers, daily products, or other customized products, RPS can adapt to different processing requirements while maintaining high quality.

Wide application areas:

RPS can be used in a variety of industries, especially in the packaging and home appliance industry is very common. In the packaging field, RPS is mainly used in food packaging, consumer goods packaging and so on. In the home appliance industry, RPS is often used to produce home appliance housings, linings and other durable components. In addition, RPS can also be used in the manufacture of auto parts and electronic components, making it the preferred material for high-performance recycling.

Product Details:

Fields of Application:

RPS is widely used in many fields such as packaging, home appliances, consumer goods, electronics and automobiles. Due to its excellent rigidity and transparency, RPS is often used in fields such as food containers, beverage cups, home appliance housings and daily product packaging. The transparency of RPS makes it particularly suitable for packaging designs that require a high transparent appearance, while its rigidity ensures that the packaging material can effectively protect the product. In addition, RPS is also used in the automotive industry for the production of automotive interior parts to enhance the quality and durability of automotive parts.

Performance and Advantages:

RPS retains the transparency and rigidity of native polystyrene, which can meet the requirements of high rigidity and visual effects. It has good processing properties and can be combined with other materials to meet the specific needs of different industries. Its excellent mechanical properties enable it to withstand high-intensity conditions of use, while its environmental properties comply with modern environmental regulations.

Production and technical advantages:

The production of RPS uses efficient recycling technology to convert waste polystyrene materials into high-quality recycled polystyrene through a fine treatment process. This process reduces the need for new materials and effectively reduces resource consumption in the production process. Compared with traditional production methods, the production process of RPS is more energy efficient and the production cost is also more advantageous. RPS can be produced through a variety of processes such as injection molding and extrusion to adapt to different industry needs.

Environmentally friendly and cost effective:

As a recycled material, RPS effectively reduces the need for natural resources in the production process and reduces the environmental impact of plastic waste. Its environmentally friendly nature enables it to meet current stringent environmental standards and is an ideal choice for all types of businesses when achieving their green production goals. Compared with new materials, the production cost of RPS is low, which enables enterprises to reduce production costs and improve economic benefits while ensuring material properties.

With its excellent transparency, rigidity and environmental protection characteristics, RPS is widely used in many industries such as packaging, home appliances, electronics and automobiles. It not only meets the market's high requirements for performance and environmental protection, but also helps companies make significant progress on the road to reducing costs and promoting sustainable development.