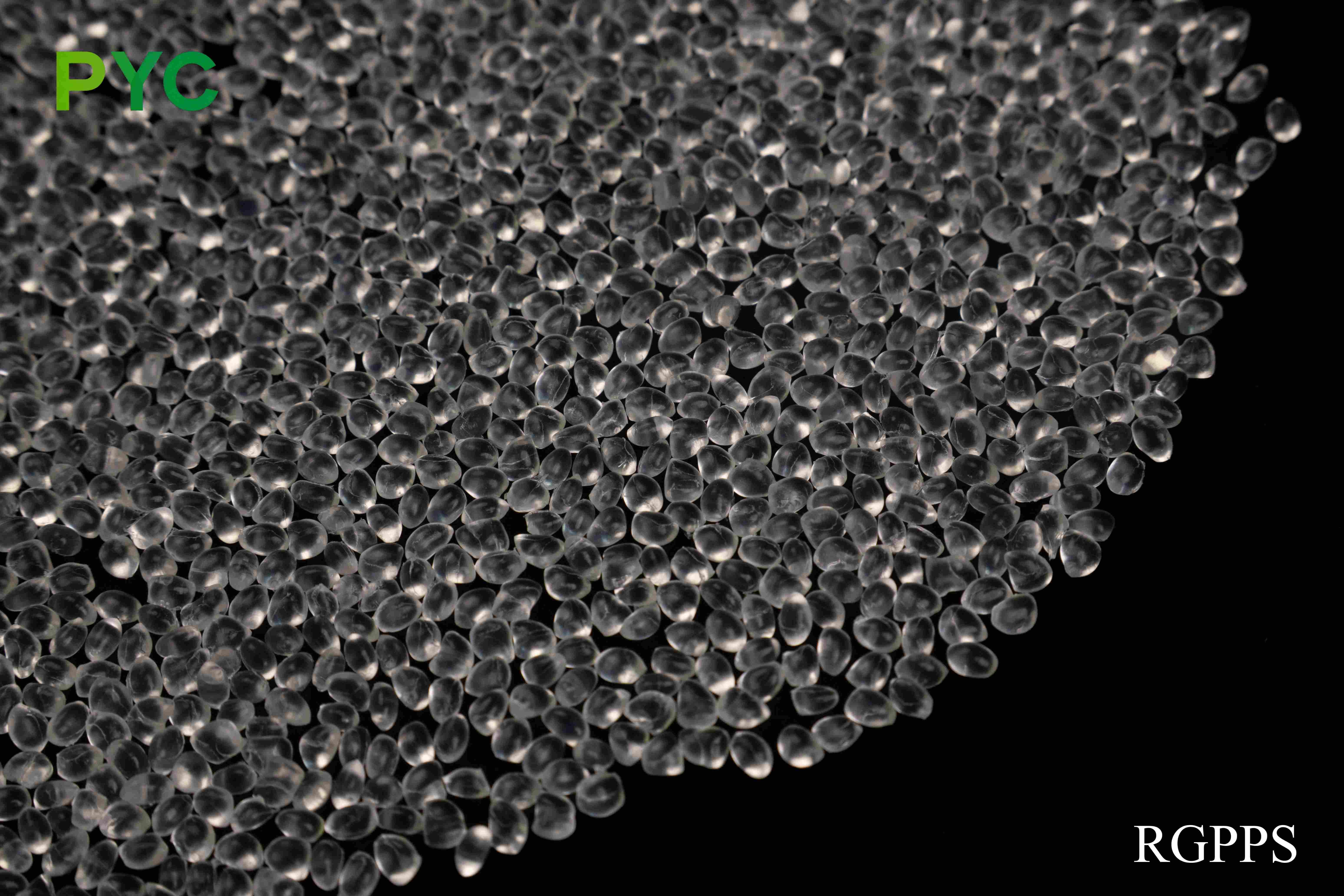

RGPPS

Product highlights:

High quality recycled raw materials

RGPPS (Recycled High Gloss Polystyrene) uses a single source, highly screened industrial recycled GPPS raw material, mainly from the following specific recycling channels:

High-gloss plastic packaging: from food packaging boxes, disposable transparent plastic containers, blister packaging, etc., these materials usually have high transparency and gloss, after cleaning treatment and strict screening after recycling, to ensure the surface flatness and optical properties of recycled materials.

Electronic product shell: including router shell, set-top box, telephone, speaker shell, etc., these materials are usually made of high-light GPPS, after classification, removal of impurities and purification treatment, to ensure high gloss and good durability.

Office supplies: mainly including transparent stationery, CD/DVD box, business card case, display stand, etc., after fine sorting, cleaning and reprocessing when recycling, to ensure that the material has good appearance quality and processing adaptability.

Injection molding waste: the use of GPPS injection molding products produced in the production process of scraps and waste, these raw materials have not been used, the quality is stable, after strict screening and purification, can effectively improve the optical performance of recycled materials and processing stability.

All raw materials are strictly screened and optimized to ensure low impurity content, giving RGPPS excellent gloss, surface flatness and stable processing performance, widely used in high-gloss packaging products, electronic products shell, office supplies and decorative materials and other fields.

Strict quality control

RGPPS undergo strict quality testing, including melt index (MFI), gloss, thermal deformation temperature, etc., to ensure its stability in different processing environments. Its excellent transparency, gloss and processing adaptability make it widely used in high transparent packaging, advertising display board, stationery and home appliance decoration parts and other fields.

Environmental protection and resource reuse:

RGPPS are made by recycling polystyrene waste, effectively reducing the environmental impact of plastic waste. It saves a lot of energy and raw materials in the production process, helps reduce the accumulation of plastic waste, and meets the needs of modern society for sustainable development.

High rigidity and transparency:

RGPPS retains the excellent rigidity and transparency of protopolystyrene, making it excellent in many applications that require a strong, clear appearance. Whether in food packaging, appliance housings, or other consumer goods, RGPPS provide high-quality visual effects and mechanical strength.

Excellent formability:

RGPPS has good flow during processing and can be produced by injection molding, extrusion and other processes to meet the needs of a variety of industries. Its excellent molding performance makes the production process more efficient and ensures the stable quality of the final product.

Economical and practical:

The recyclability of RGPPS makes it cheaper to produce than native polystyrene, while not inferior in performance. When choosing RGPPS, enterprises can not only reduce production costs, but also meet the needs of environmental protection and sustainable development.

Product details:

Fields of Application:

RGPPS are widely used in many industries, especially in packaging, home appliances, consumer goods and other fields. In the packaging industry, RGPPS are used in food containers, cups, packaging boxes for daily consumer goods, etc., due to their transparency and high rigidity, they are able to provide solid protection and good visual effects. In the field of home appliances, RGPPS are used to produce components such as home appliance housings and linings, ensuring the durability and aesthetics of the products. In addition, RGPPS are widely used in automotive, electronic products, stationery and other industries.

Performance and Advantages:

RGPPS has high rigidity and transparency, can withstand greater external force and is not easy to deform, and is suitable for products requiring high mechanical strength. Its good transparency makes it especially favored in the field of packaging, at the same time, its excellent formability makes the processing more efficient. Compared with the original polystyrene, RGPPS can meet the dual requirements of the market for environmental protection and performance while reducing production costs.

Production and technical advantages:

The production of RGPPS converts waste polystyrene into high-quality recycled materials through efficient recycling techniques. During the production process, through an optimized recycling process, RGPPS maintains good mechanical properties and physical properties. Compared with traditional materials, the production process of RGPPS is energy efficient and environmentally friendly, while helping companies reduce production costs.

Environmental protection and cost effectiveness:

By recycling waste materials for production, RGPPS reduces dependence on natural resources and meets the needs of modern enterprises for environmental protection. Due to their low production costs, RGPPS has become an ideal choice for enterprises in many industries to reduce production costs. Compared with new materials, the price advantage of RGPPS makes it more competitive in the market.

As a kind of highly rigid, transparent and environmentally friendly recycled material, RGPPS has a wide range of applications in many industries. It not only helps to promote green production and sustainable development, but also provides companies with a solution that is both economical and environmentally friendly.