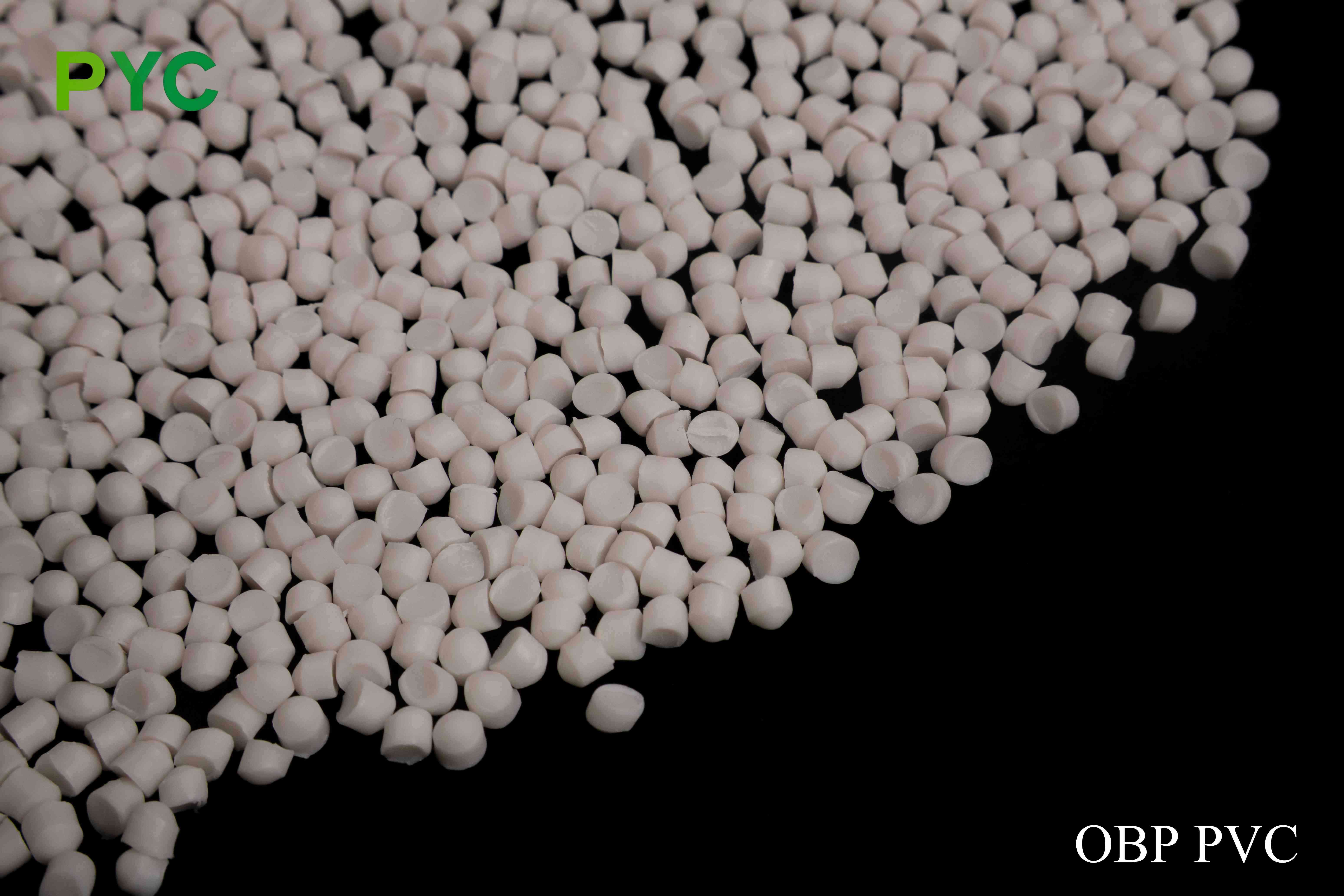

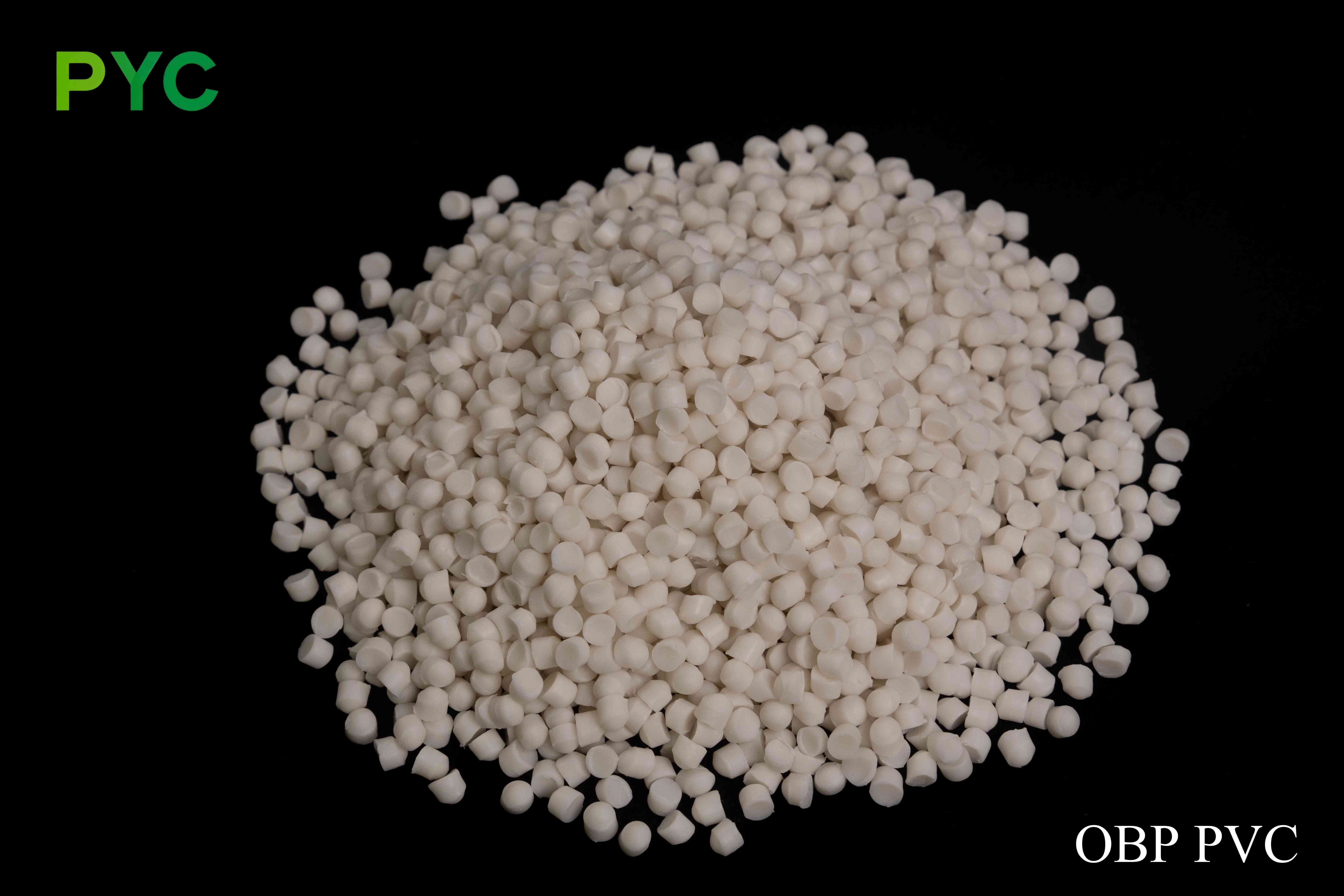

OBP PVC

Product Highlights

High quality recycled raw material source

OBP PVC (polyvinyl chloride for Marine plastic recycling) is derived from plastic waste that is on the verge of entering the ocean, mainly including:

Discarded fishing supplies: old fishing nets, buoys, fish boxes, plastic ropes, etc.

Construction and pipe waste: discarded PVC pipes, door and window frames, guardrail and other building materials near the shoreline.

Industrial packaging materials: PVC film, tarps, cable sheathing and other industrial products.

These recycled materials undergo rigorous screening, deep cleaning and fine sorting to ensure high purity and stability of the material to meet the needs of different applications.

Strict quality control

Raw material screening: remove impurities and pollutants to ensure that recycled PVC has a high purity.

Efficient cleaning: The use of environmentally friendly solvent cleaning, remove salt, oil and attachments, improve the cleanliness of materials.

Optimization regeneration: through high temperature melting, filtration, modification and other processes, improve the weather resistance and mechanical properties of PVC.

Quality testing: Strict testing of tensile strength, impact toughness, thermal stability and other key indicators to ensure that products meet industry standards.

Excellent performance, widely used

OBP PVC has good corrosion resistance, aging resistance and excellent mechanical properties, suitable for:

Construction industry: recycled PVC pipes, profiles, guardrail, waterproof materials.

Industrial application: cable sheath, auto parts, chemical equipment protective layer.

Fishery and Marine engineering: fishing nets, buoys, Marine floats, etc.

OBP PVC provides high performance and environmental protection PVC material solutions for sustainable development through high purity selected raw materials and strict quality control.

Product Details

1. Environmental protection and sustainability

OBP PVC is produced from OceanBound Plastic, which can effectively reduce Marine pollution. By recycling plastic waste within 50 km of ocean boundaries, OBP PVC not only reduces environmental pollution, but also reduces carbon emissions, contributing to the sustainable development of the plastics industry. The material is widely used in construction, automobiles, home appliances, pipes and packaging, and has promoted the transformation of the global green economy.

2. Corrosion resistance and weather resistance

OBP PVC has excellent acid and alkali resistance, corrosion resistance, and can withstand harsh chemical environments. Its good UV resistance makes it excellent in outdoor applications, suitable for water pipes, pipe housings, outdoor cables and building decoration materials. Even in severe weather conditions, OBP PVC can remain stable for a long time, is not easy to embrittlement and fade, and has excellent aging resistance.

3. Mechanical properties and processing properties

OBP PVC has high strength and rigidity, and has good toughness and impact resistance. In terms of processing performance, OBP PVC is easy to pass a variety of processing processes such as injection molding, extrusion and calendering, and is suitable for complex shapes and mass production. In addition, OBP PVC has good fluidity, ensuring uniform filling in the injection process, improving the production efficiency and yield of the product.

4. High cost performance and wide application

Compared with other high-performance plastics, OBP PVC has significant advantages in terms of cost effectiveness, while maintaining good performance stability, suitable for large-scale applications. OBP PVC has a wide range of applications in construction, pipe, home appliance shell, packaging materials and other fields, especially suitable for construction pipes, window frames, outdoor facilities, storage boxes, packaging containers and other products, to provide customers with cost-effective solutions.

5. Wide application and market demand

OBP PVC has a wide range of applications in several industries, including: Construction industry: piping, wire sheathing, wall panels

Home appliance industry: refrigerator shell, air conditioning parts, electrical switch box

Packaging industry: food packaging, beverage bottles, storage containers

Automotive industry: automotive interior parts, window frame seals, cable sheathing

Outdoor equipment: outdoor furniture, cable protection, lighting facilities