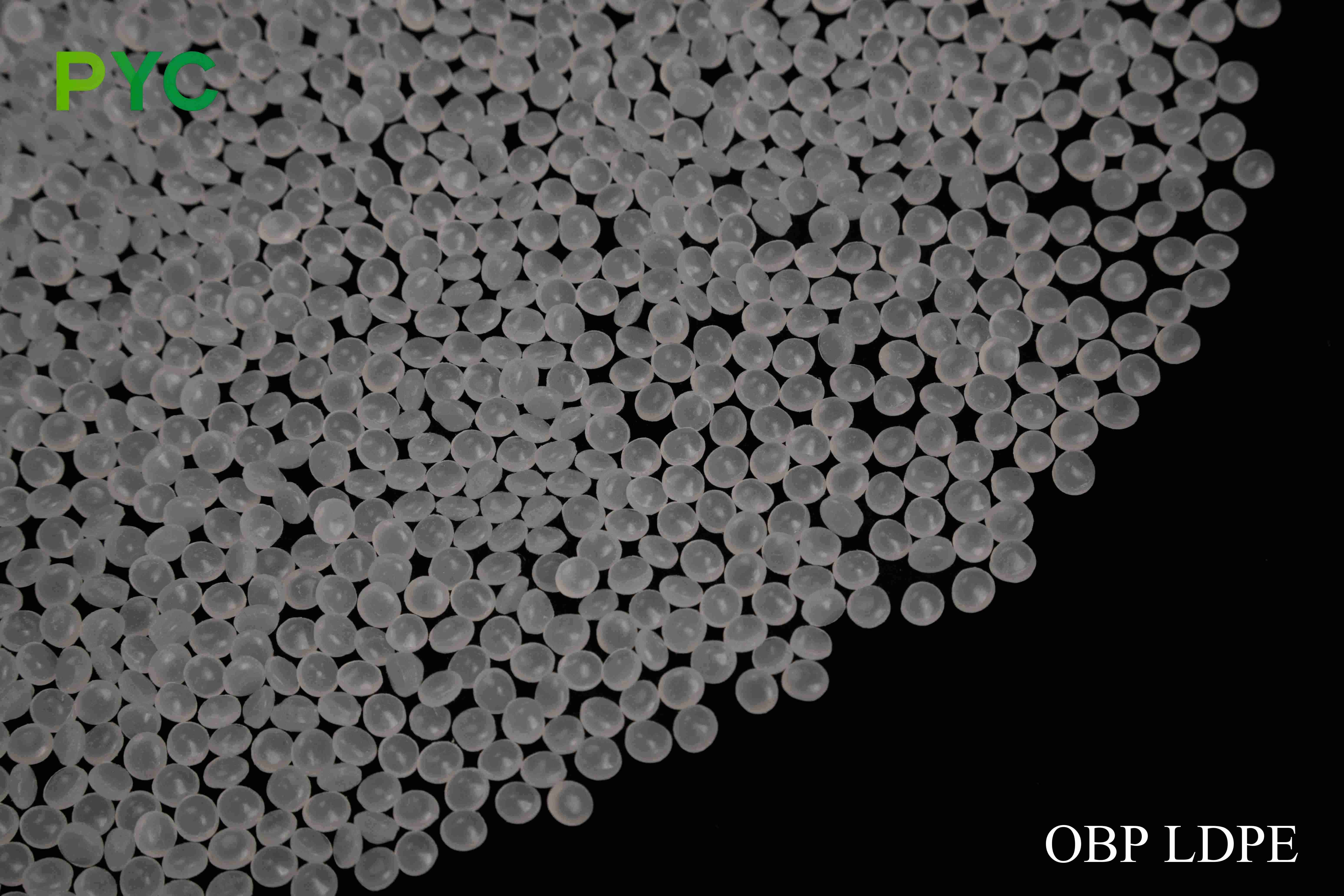

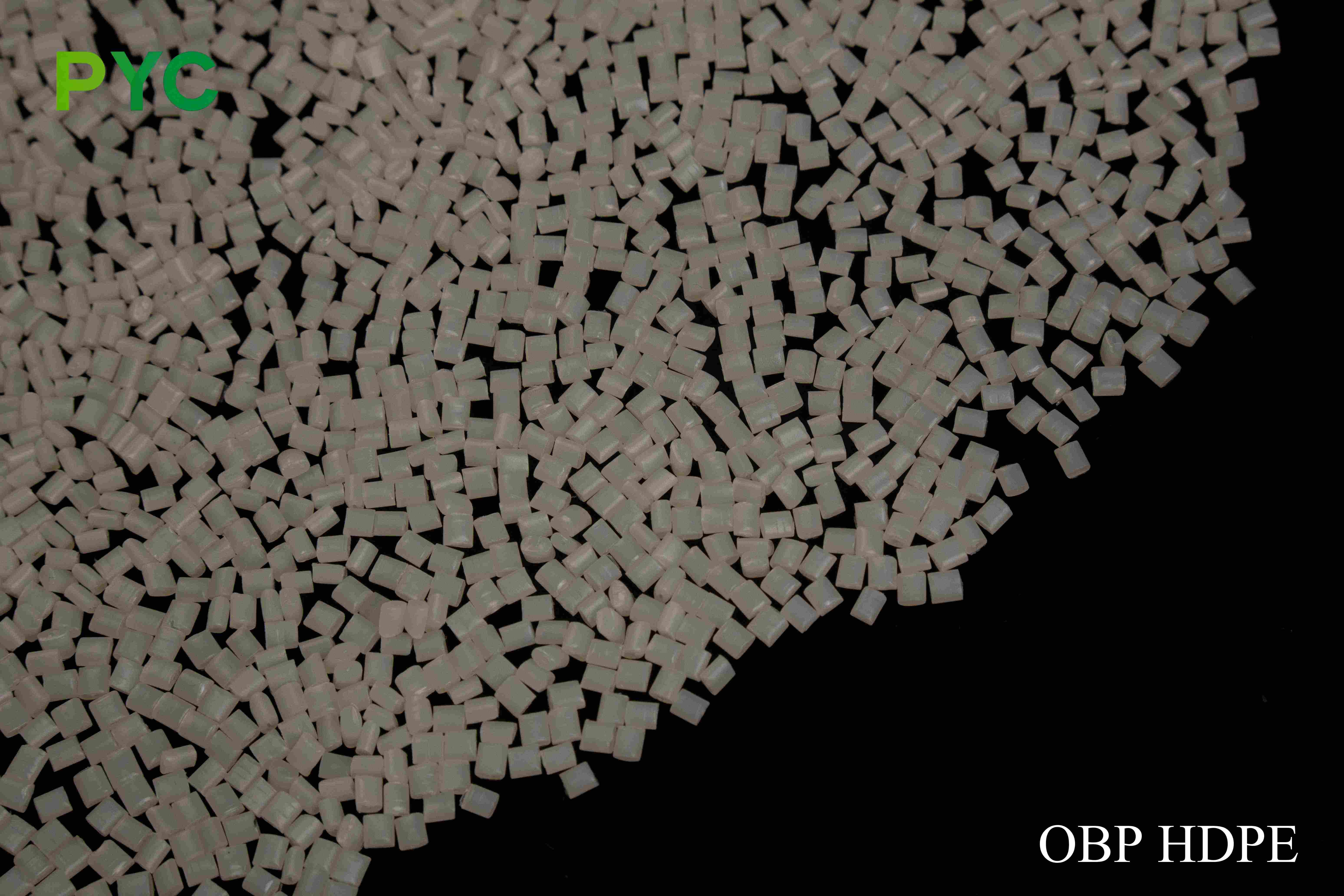

OBP LDPE

Our OBP LDPE (Ocean-Bound Plastic Low-Density Polyethylene) is an eco-friendly material sourced from plastic waste collected near coastal areas, preventing it from entering the ocean. This sustainable LDPE alternative retains the excellent flexibility, impact resistance, and processability of traditional LDPE while promoting environmental responsibility.

product details

High purity of selected raw materials to ensure superior quality

Recycled LDPE (Low Density Polyethylene) is selected from a single source of high purity, mainly from industrial trimmings, used packaging films, agricultural films, injection molding waste, etc. These raw materials come from reputable upstream manufacturers. These rawmaterials come from reputable upstream manufacturers and undergo rigorous screening without additional cleaning to ensure low impurities and high stability, providing quality assurance for high-end applications.

Industrial

Derived from LDPE plastic segments not used in the manufacturing process, it is rigorously screened to ensure purity and consistent performance.

Waste packaging

This includes recycled used packaging film, usually originating from the food and commodity sectors, which is processed through a cleaning and screening process to ensure low impurities.

Agricultural film

Recycled material derived from agricultural film that retains excellent plasticity and durability after clean processing.

Injection Molding Scrap

Scrap from the injection molding process is finely screened and processed to ensure the stability and excellent performance of recycled LDPE.

Recycling source: OBP LDPE plastic particles are mainly from the high purity LDPE waste recovered near the coastline, such as

discarded food packaging bags, damaged storage barrels, blow molding corners, waste pipe waste and agricultural plastic film and so on. Henan Pingyuan New Materials Co., Ltd. through the establishment of a sound recycling network, with the local recycling enterprises, environmental protection organizations in close cooperation, to ensure the stable collection of these high-quality raw materials. The recycled raw materials are strictly screened and sorted to remove impurities and other material mixes, to ensure that the raw material composition is single, high purity, no additional impurities, so as to improve the stability of the material and the subsequent product quality of OBP LDPE plastic particles.

Material performance characteristics

Flexibility and elasticity: The product made of flexibility and elasticity is excellent, can be bent and folded at will and is not easy to damage. In the packaging industry, the film can be tightly fitted to various shapes of items; In the field of toy manufacturing, the production of plastic toys can withstand repeated play by children.

Transparency: The plastic products made have good transparency, which can clearly show the state of food in food packaging and enhance consumers' desire to buy; In stationery manufacturing, it is used to make file bags, etc., to facilitate the viewing of internal documents.

Low temperature resistance: in a low temperature environment, the finished product can still maintain good physical properties, will not become brittle and crack. In the cold chain logistics packaging, it can withstand the test of low temperature to ensure the safety of the goods during transportation.

Henan Pingyuan New Materials Co., LTD. OBP LDPE plastic particles, with its unique recycling source, excellent product data and excellent material performance characteristics, in many industries show great application potential, to promote the sustainable development of various industries to provide strong support, become a new model of green development of plastic industry.