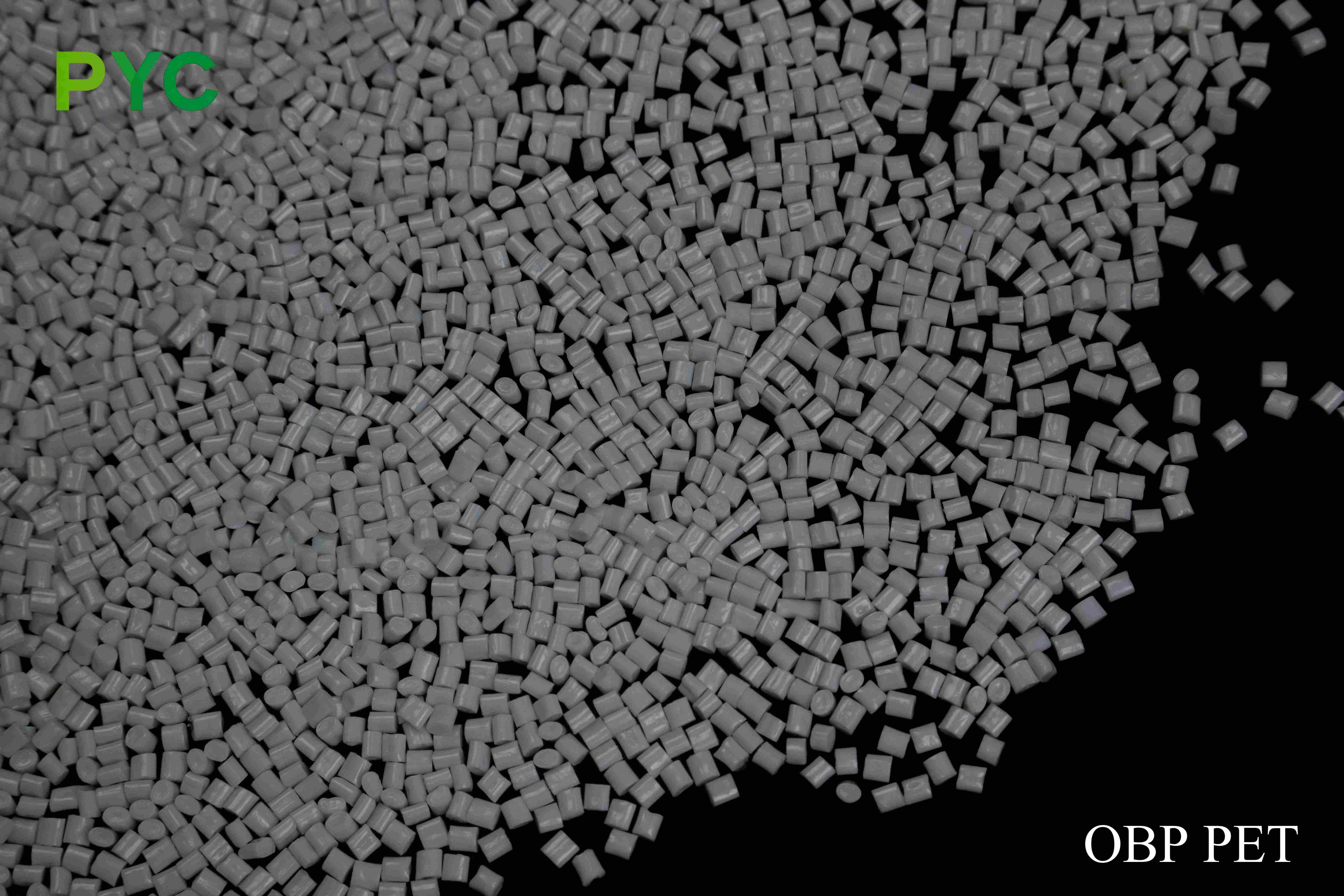

OBP PET

Our OBP PET is a high-performance material that combines the benefits of Optical Brightening Agents (OBAs) with the durability and versatility of Polyethylene Terephthalate (PET). This product is specifically engineered to enhance the brightness and optical appearance of PET-based applications, making it an ideal choice for products requiring high visual appeal and clarity. With excellent mechanical properties and environmental resistance, OBP PET serves a wide range of industries.

Product Details

High purity of selected raw materials to ensure superior quality

Recycled PET (polyethylene terephthalate) is selected from a single source with high purity, mainly from used bottles, beverage bottles, food packaging materials, fiber waste, etc.. All raw materials come from reputable upstream manufacturers and undergo rigorous screening without additional cleaning to ensure low impurities and high stability of the material, providing quality assurance for high-end applications.

waste bottle

It is mainly derived from recycled plastic bottles, such as beverage bottles and mineral water bottles, which are strictly screened and cleaned to ensure high purity and physical properties.

bottle

This includes recycled PET bottles from the beverage industry, which are processed through efficient cleaning and screening to ensure that they are of consistent quality and meet environmental requirements.

Food packaging materials

PET packaging materials recycled from the food industry are carefully screened and processed to ensure high transparency and good mechanical properties.

fiber waste

PET fiber waste from the production process is finely screened and cleaned to ensure low impurities and enhance the stability of the final product.

Recycled PET raw materials from these sources ensure that the final products are superior in terms of mechanical properties, transparency, durability and environmental friendliness for a wide range of high-end applications.

Environmentally sustainable: OBP PET uses OceanBound Plastic to reduce marine pollution and promote plastic recycling.

Excellent transparency and optical properties: High transparency for food packaging, beverage bottles and optical films.

High Strength and Impact Resistance: OBP PET has excellent mechanical properties and high tensile strength for high load applications.

Chemical resistance and safety: resistant to acids, alkalis, oils and fats, meets food-grade safety standards, can be used in medical and food industries.

In today's era of pursuing sustainable development, Henan Pingyuan New Materials Co., Ltd.

actively responds to the call for environmental protection and focuses on the production of OBP PET plastic particles, setting a benchmark for the field of plastic recycling.

A unique source of recycling

OBP PET plastic particles, produced by Henan Pingyuan New Materials Co LTD, have an extensive and targeted raw material recycling network. The raw materials of OBP PET plastic particles mainly come from the waste polyethylene terephthalate products within 50 kilometers from the coastline, such as Marine plastic, coastline waste, and river flotsam.

In terms of Marine plastic recycling, Henan Pingyuan New Materials Co., Ltd. focuses on Marine floating materials, such as recycling fishing nets, buoys, beverage bottles and so on. These

Marine plastics have been floating in the ocean for a long time, posing a serious threat to the Marine ecological environment. By recycling them, not only can Marine pollution be effectively reduced, but also resources can be reused. Taking recycling fishing nets as an example, a large number of discarded fishing nets drift wantonly in the ocean, entangling Marine organisms and destroying the Marine ecological balance. Henan Pingyuan New Materials Co., Ltd. recycles them, giving these discarded fishing nets a new value.

For shoreline waste, Henan Pingyuan New Materials Co., Ltd. organized a professional team to collect PET debris scattered on beaches and coastal industrial zones. On the beach, due to tourist activities and ocean tides, a large number of PET products will be left behind, and coastal industrial areas will also produce some discarded PET materials. Henan Pingyuan New Materials Co., Ltd. collects the waste for subsequent treatment to prevent it from further polluting the coastal environment.

In the river system, Henan Pingyuan New Materials Co., Ltd. has set up interception devices to intercept and sort PET waste carried in the river, such as beverage bottle caps and packaging films. The river is an important channel connecting the land and the sea, and a large amount of PET waste enters the sea through the river. The treatment of PET waste in the river by Henan Pingyuan New Materials Co., Ltd. reduces Marine plastic pollution from the source.

Advanced production technology

Physical separation: Henan Pingyuan New Materials Co., Ltd. uses mechanical crushing, wind separation, eddy current separation and other physical separation technology to remove impurities from the collected raw materials. Mechanical crushing will be large pieces of waste polyethylene terephthalate products crushed into small pieces, easy to follow-up treatment; Wind separation using different material density is different, under the action of wind to achieve separation; Eddy current separation can effectively remove impurities such as metals and ensure the purity of raw materials.

Cleaning and drying: The raw materials after physical separation will be cleaned at high temperature to remove the dirt and impurities on the surface. The gradient drying technique is then used to precisely control the degree of drying and prepare the material for subsequent processes. High temperature cleaning can effectively kill the bacteria and microorganisms attached to the raw materials, and gradient drying can ensure that the water content of the raw materials meets the production requirements.

Melt extrusion and performance optimization: the dried raw materials are made into particles by melting extrusion and other processes. Henan Pingyuan New Materials Co., Ltd. also uses molecular chain repair technology to optimize the performance of recycled PET to ensure that its characteristics are close to the raw material, such as the characteristic viscosity ≥

0.75dL/g, acetaldehyde content ≤10ppm. Molecular chain repair technology can repair the molecular chain damaged in the recycling process and improve the quality of OBP PET plastic particles.

A wide range of applications

Packaging and daily necessities: OBP PET plastic particles produced by Henan Pingyuan New Materials Co., Ltd. can be used to produce environmentally friendly mineral water bottles and food-grade fresh-keeping boxes, replacing traditional petroleum-based materials and providing consumers with a more environmentally friendly choice. It is also widely used in the production of cosmetics bottles and detergent containers, and has passed the food contact material certification of the US FDA to ensure the safety of contact with food.

Textile and Industry: OBP PET plastic particles produced by Henan Pingyuan New Materials Co., Ltd. can make recycled polyester fiber (rPET) clothing, yoga MATS, and enhance the circular economy value. In the industrial sector, industrial filter materials and electronic component shells are developed to meet the needs of different industries by using their chemical resistance and high rigidity.

OBP PET plastic particles produced by Henan Pingyuan New Materials Co., LTD, with unique recycling sources, advanced production processes, excellent product performance, a wide range of application fields and significant technical and market advantages, occupy an important position in the plastic recycling industry and make important contributions to promoting sustainable development.