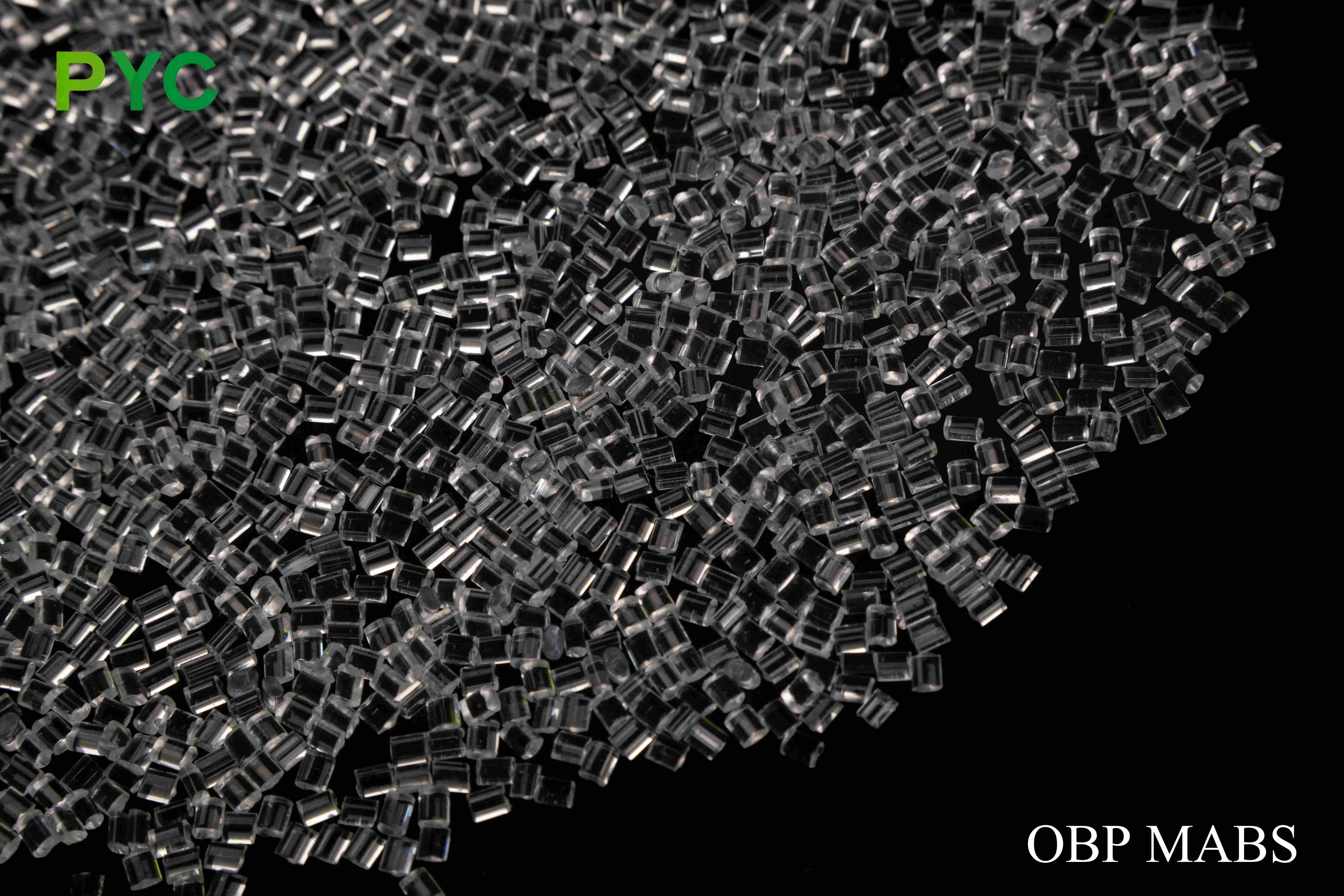

OBP MABS

OBP MABS product documentation

Product Highlights

Ok, according to your request, I will write these recycled sources into the template:

High quality raw materials

Dyeing ABS is made of selected recycled ABS raw materials, which come from a single source and have been strictly screened by upstream manufacturers to ensure their purity and consistency. The sources of recycled ABS include:

Electronic product shell: such as TV shell, home appliance panel, computer shell, etc., to ensure that the material has good impact resistance and high temperature resistance, to adapt to the high requirements of the electronics industry.

Auto parts: such as automotive interior parts, lamp shell, instrument panel, etc., recycled ABS has excellent toughness and can withstand strong physical impact.

Household plastic products: such as kitchen utensils, furniture accessories, to ensure that the recycled ABS has good processing stability and long-term durability.

Industrial waste: such as injection molding scraps, scrap sheets, etc., provide efficient and stable raw materials.

Packaging materials: such as plastic packing boxes, packaging sheets, etc., recycled ABS has excellent processing performance.

The material is specially treated to ensure that the recycled ABS retains its excellent mechanical properties, toughness and heat resistance, providing a stable basis for the dyeing process, thus ensuring the superiority of the final product in color performance and physical properties, suitable for a variety of high-end applications.

This more specifically lists the sources from which the ABS is recycled. Hope this helps!

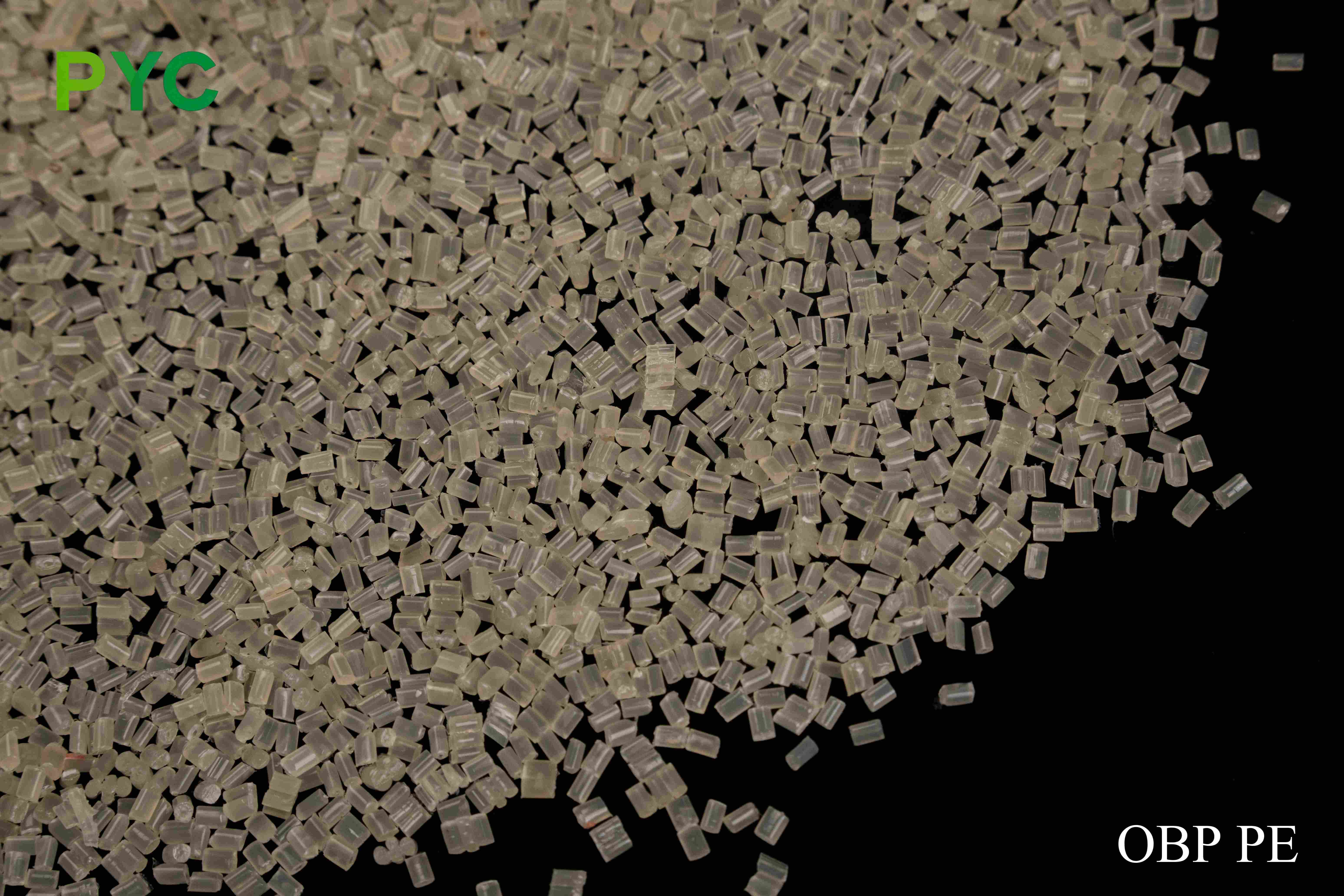

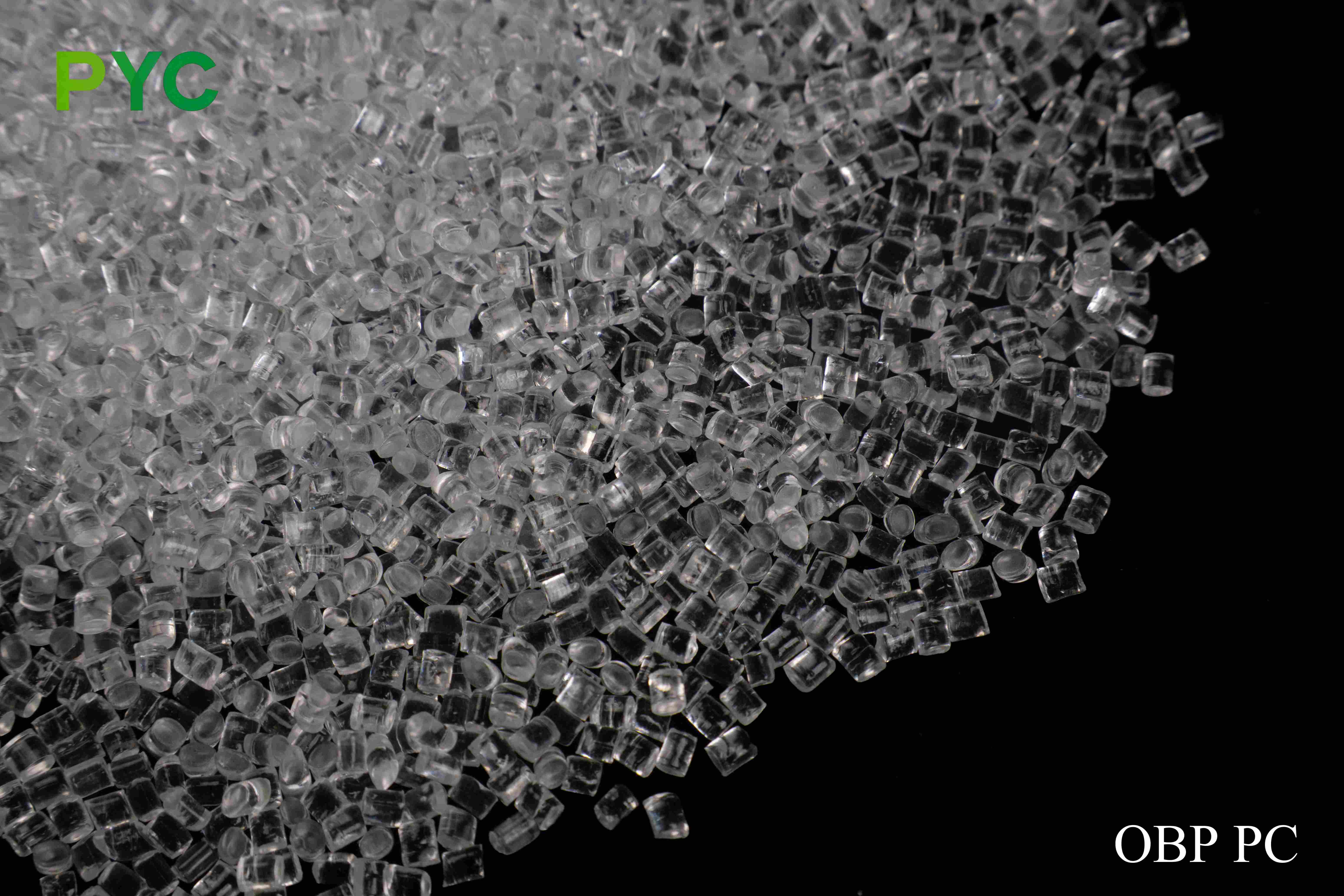

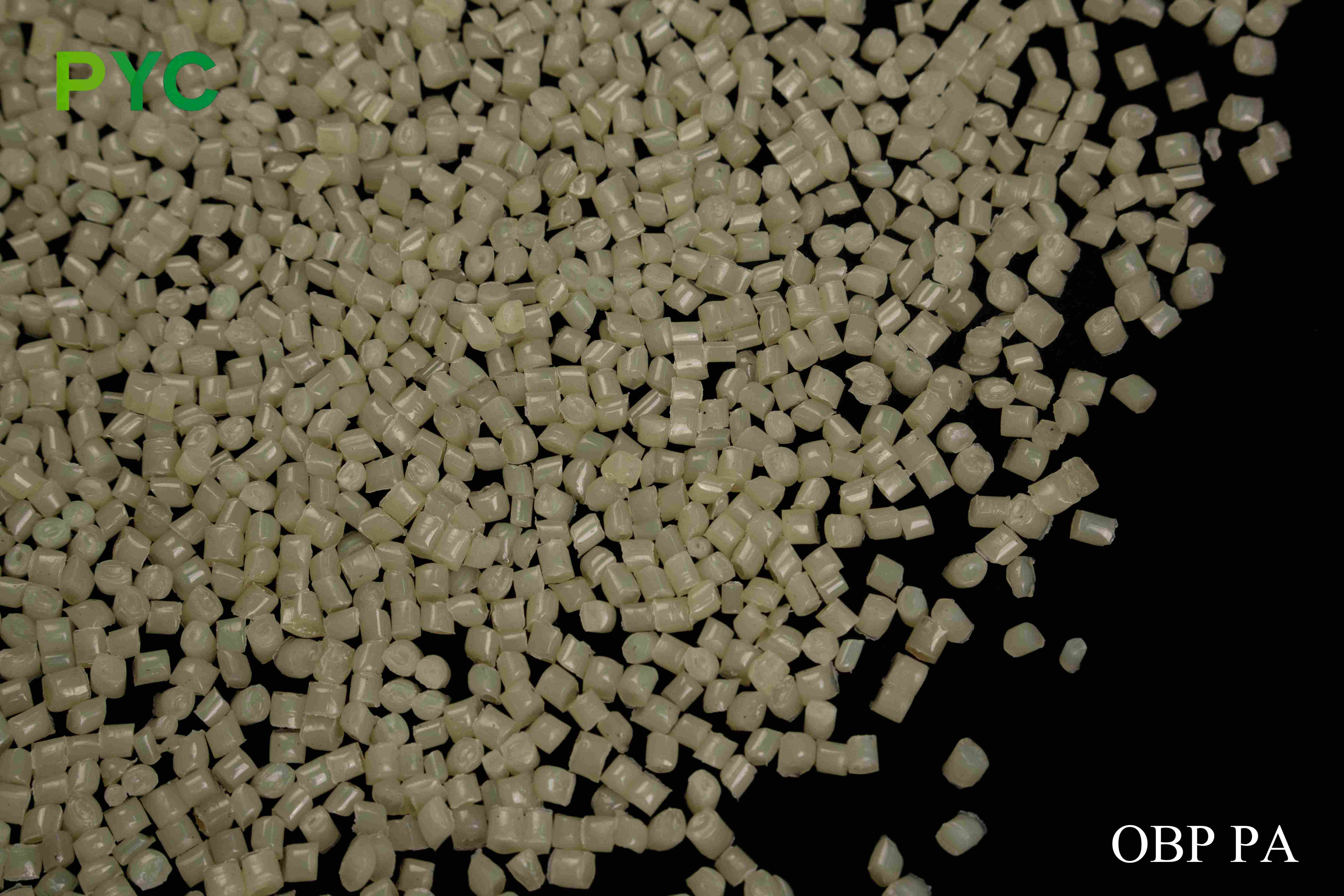

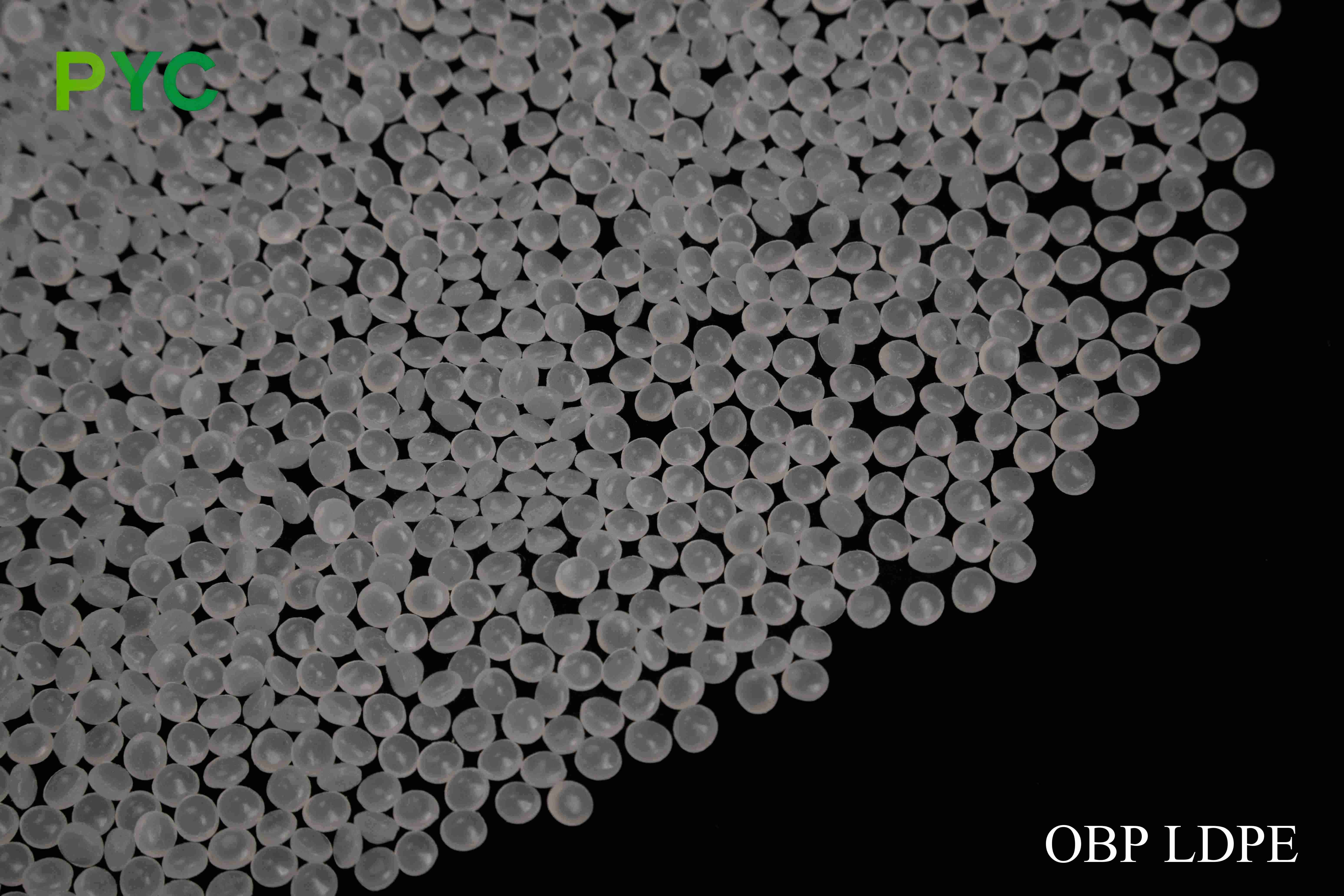

Marine Recycled Plastics (OBP) Environmental concept

OBP MABS uses OceanBound Plastic (OBP) as the main raw material, which is derived from recycled waste within 50 km of the coastline, effectively reducing Marine plastic pollution and in line with the global sustainable development trend.

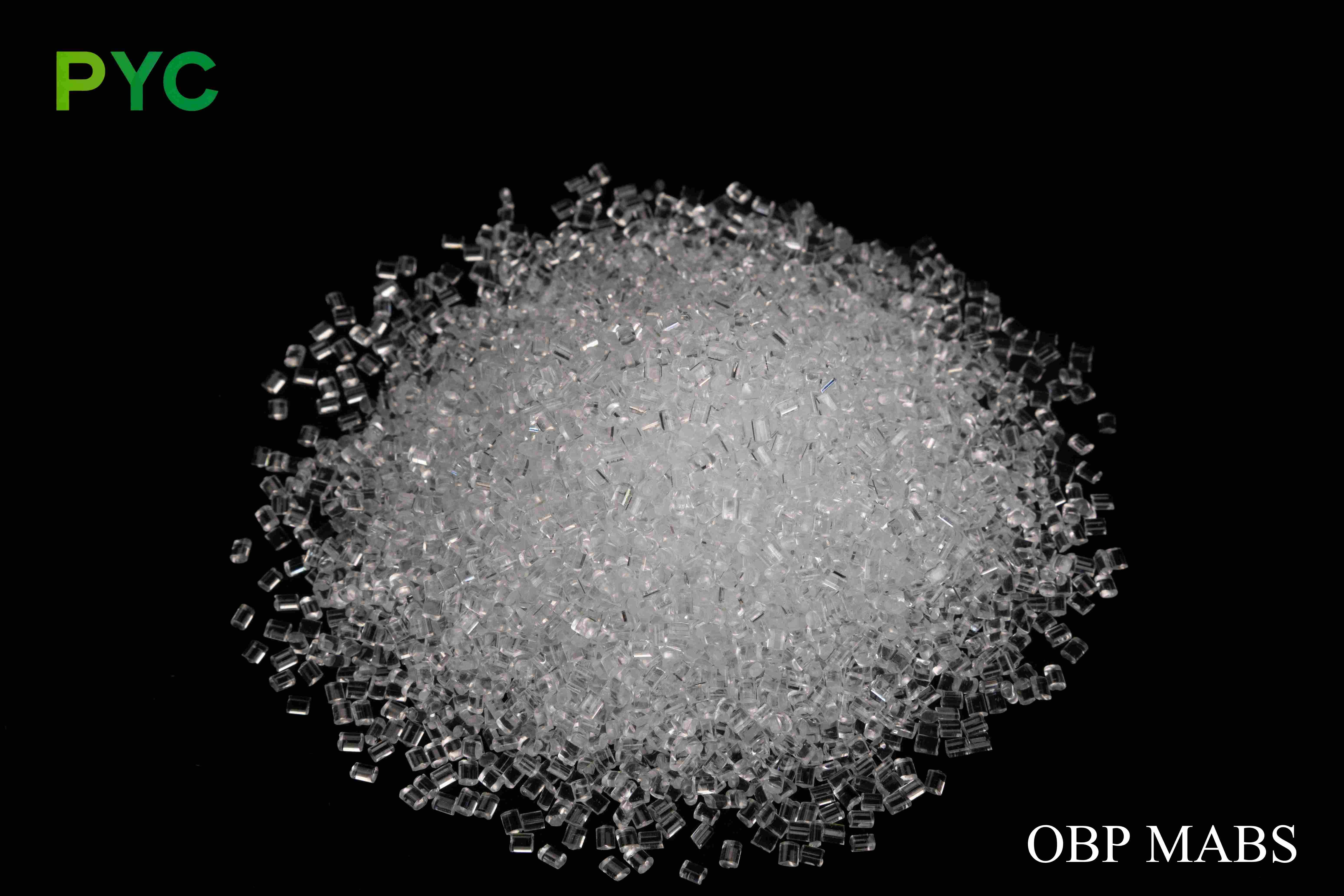

Excellent mechanical properties

OBP MABS combines the MABS material's high gloss, excellent impact resistance and good rigidity, while enhancing its wear resistance, heat resistance and chemical resistance through modification to meet the needs of high-end applications such as electronic products, home appliance housings and automotive parts.

Excellent processing adaptability

Compatible with a variety of processing methods, including injection molding, extrusion and thermoforming, excellent fluidity, suitable for complex structure and precision molding product manufacturing, reduce production difficulty, improve efficiency.

Environmental protection and sustainable, in line with international standards

The adoption of OBP certification for recycled plastics helps to reduce plastic pollution, reduce carbon footprint, comply with global environmental regulations (such as RoHS, REACH), and is suitable for industries with strict requirements for sustainable development.

A wide range of application fields

It is suitable for many fields such as consumer electronics, home appliance shell, auto parts, 3D printing consumables, etc., to meet the high-end market's demand for environmentally friendly, durable and high-gloss materials.

Details Description (Details)

OBP MABS is a high-performance environmentally friendly plastic developed specifically for consumer electronics, home appliances, auto parts and other industries with high requirements for strength, gloss and environmental protection. The product uses Marine recycled plastic (OBP), mainly from the high purity MABS waste recycled near the coastline, such as electronic product shells, scraps in industrial production and unused finished waste, to ensure a single composition, high purity, no additional impurities, from the source to ensure the performance stability and sustainability of the material.

In the production process, we use advanced modification technology, so that OBP MABS has high gloss, high toughness, impact resistance, wear resistance excellent characteristics, and optimize the fluidity of the material, so that it is suitable for precision injection molding, extrusion and thermal molding and other processing methods. In addition, the chemical and heat resistance of OBP MABS enables it to maintain stable performance in harsh environments, especially for long-term use in consumer electronics and high-end home appliances.

As an environmentally friendly material, OBP MABS meets the requirements of sustainable development while providing high performance. Instead of additional cleaning of raw materials, we directly source highly screened, high-quality recycled MABS, ensuring extremely low impurity levels, thereby reducing energy consumption and environmental impact. Whether in industries such as electronics, home appliances, automotive manufacturing or 3D printing, OBP MABS meets the market demand for high performance, environmentally sustainable materials.