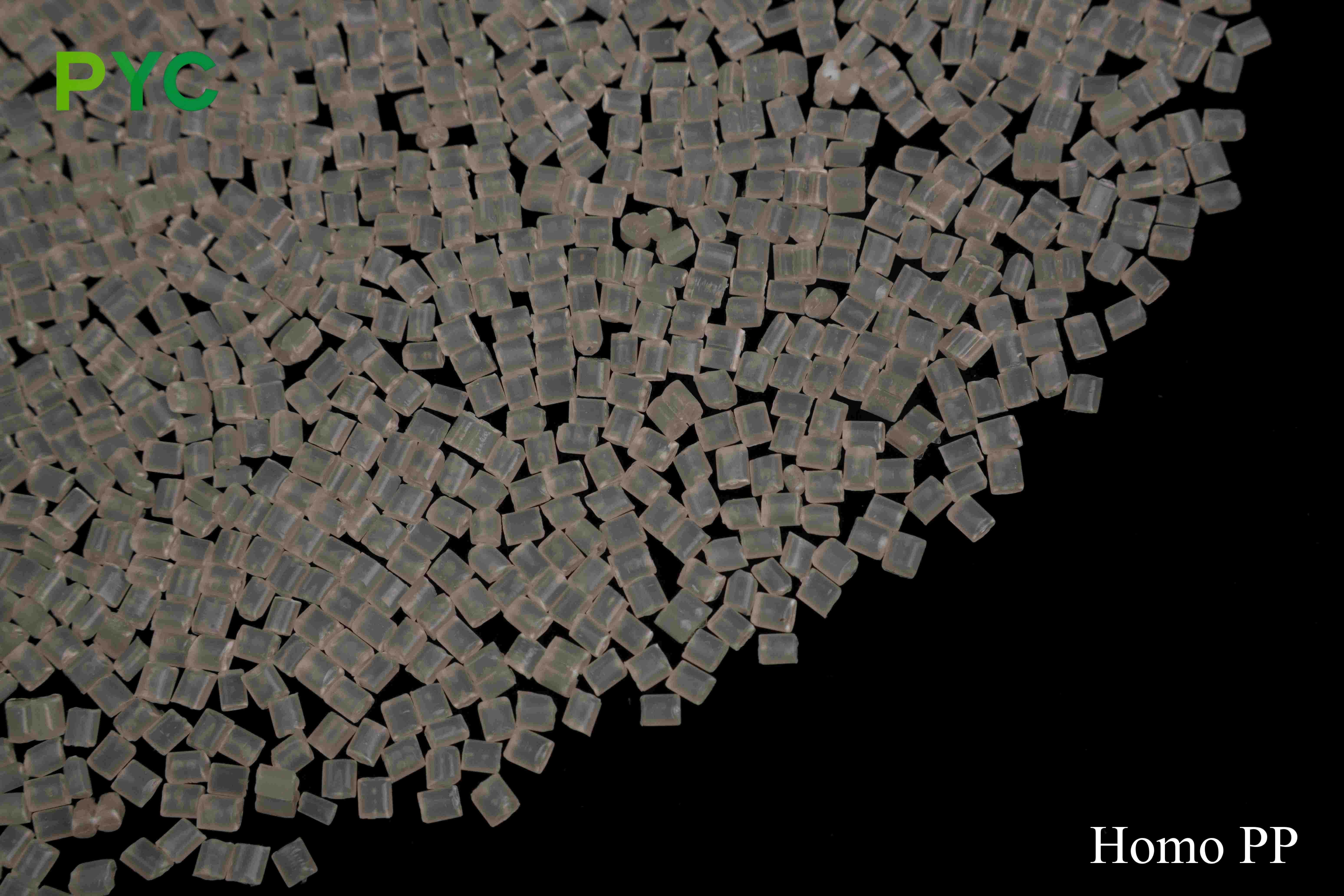

Homo PP

Product highlights:

High quality recycled raw materials

RHomo PP (Recycled Homopolymer polypropylene) uses a single source, highly screened industrial homopolymer PP raw material, the main sources include the following specific recycling channels:

Plastic household items: from plastic chairs, storage boxes, trash cans, trays, etc., these products use high crystallity homopoly PP, recycled after crushing, cleaning, removal of impurities and re-granulation, to ensure excellent mechanical strength and heat resistance.

Packaging materials: mainly includes food-grade plastic boxes, express bags, bottle caps, thin-wall containers, takeout lunch boxes (non-food residual waste), the surface of these materials is smooth, after recycling after cleaning, crushing and melting filtration, to ensure high purity and good processability.

Industrial supplies and building materials: the use of plastic pipes, cable protective covers, industrial pallets, chemical barrels, woven bags, plastic film and car bumpers, these materials in the recovery after removal of impurities, crushing cleaning, drying and melting granulation, to ensure the high rigidity and chemical resistance of recycled materials.

Industrial production waste: including injection molding, extrusion, blow molding and other processes produced by homopyPP scraps and defects, these raw materials are not used, stable quality, through direct recovery, purification and granulation, can ensure the stability of recycled materials and consistent physical properties.

All raw materials are fine screening and optimization treatment to ensure low impurity content, giving RHomo PP excellent rigidity, high heat resistance and good processing adaptability, widely used in household goods, packaging materials, industrial parts, building materials and high heat resistance structural parts and other fields.

High rigidity and heat resistance

Homo PP has excellent rigidity and heat resistance, can remain stable in high temperature environment above 100°C, and is suitable for microwave heating food packaging, hot water pipes, home appliance shells, etc. Compared to Copo PP, HOMO PP is more than 30% more rigid and suitable for high load applications.

Excellent chemical stability

Homo PP has excellent chemical resistance and is resistant to most acids, bases and organic solvents. Therefore, it is widely used in chemical containers, pharmaceutical packaging, laboratory equipment, etc., where corrosion resistance is required.

Good processing performance

Homo PP has a high melting index, good fluidity, suitable for injection molding, blow molding, extrusion and other processing processes, can be used to produce high-precision, high-stability products, improve production efficiency, reduce production costs.

Food grade safety standards

Homo PP is non-toxic and odorless, in line with FDA, EU and other international food safety standards, and is widely used in food packaging, disposable tableware, beverage bottle caps and other products to ensure food contact safety.

Product Details:

Field of application

Food and Packaging industry:

Suitable for microwave food containers, food trays, plastic bottle caps, disposable tableware, etc., to ensure food safety and heat resistance.

Its high transparency and excellent sealing properties make it an ideal food packaging material.

Home Appliances and Electronics Industry:

Because of its high rigidity and excellent heat resistance, Homo PP is widely used in washing machine inner bucket, rice cooker shell, air conditioning blade and so on.

In electronic product housings and structural parts, Homo PP can provide good mechanical stability and anti-aging properties.

For the automotive industry:

Suitable for automotive interior parts, dashboards, door panels and other parts with high rigid requirements, help to reduce the weight of the car and improve fuel economy.

Due to its low density and high crystallinity, Homo PP can effectively reduce vehicle carbon emissions while ensuring durability.

Medical and Hygiene Products:

Because Homo PP has non-toxic, high temperature resistance, corrosion resistance and other characteristics, it is widely used in the field of disposable medical equipment such as syringes, medicine bottles, medical kits.

Its recyclability and recyclability make it an important material for sustainable development in the medical field.

Performance Advantages

High crystallinity, strong rigidity, suitable for high-load structural parts.

High temperature resistance, high melting point, can be used for microwave heating and hot water contact applications.

Resistant to chemical corrosion, suitable for laboratory, medical and chemical applications.

Superior processing performance, suitable for all kinds of molding process, improve production efficiency.

In line with food grade safety standards, suitable for food packaging and medical fields.

Sustainable development and environmental protection

Homo PP is recyclable, complies with environmental regulations, reduces plastic pollution and reduces raw material consumption. With the advancement of the global Sustainable Development Goals, Homo PP has become a high-performance, environmentally friendly option in several industries to help companies achieve green manufacturing.

With its excellent rigidity, heat resistance, chemical stability and environmental protection properties, Homo PP has become an important material in modern industrial production and is widely used in many industries to meet the needs of different markets.