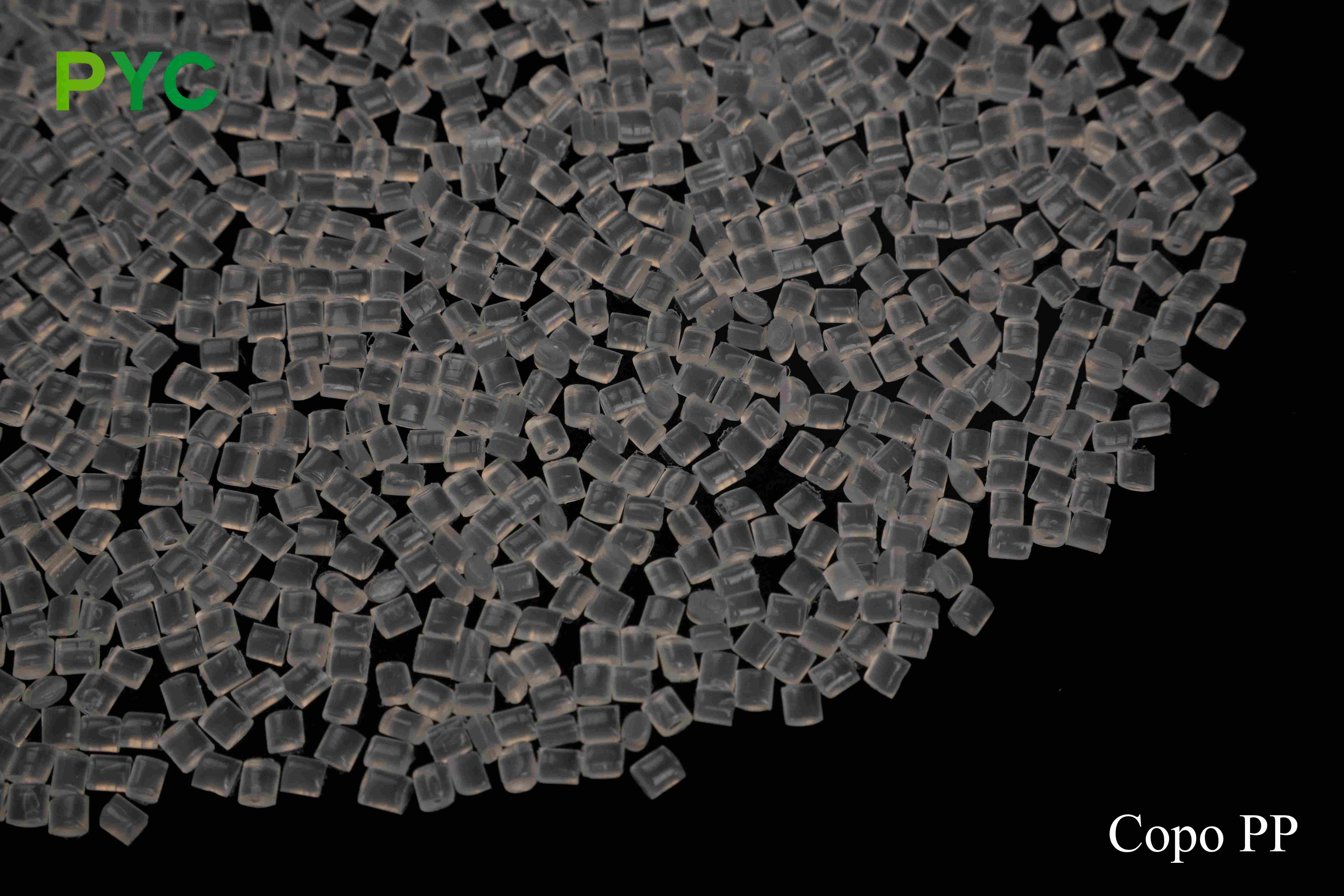

Copo PP

Product highlights:

High quality recycled raw materials

RCopo PP (Recycled Copolymer polypropylene) uses a single source of highly screened industrial recycled copolymer PP raw materials, the main sources include the following specific recycling channels:

Automotive plastic parts

From car bumpers, instrument panels, door interior panels, battery shells, etc., these parts are usually made of high impact copolymer PP, after disassembly, crushing, cleaning, removing impurities and re-granulizing to ensure excellent mechanical properties and processing stability.

Home appliance shell and parts: mainly including washing machine shell, refrigerator liner, air conditioning shell, vacuum cleaner parts, etc. These products are made of high toughness PP copolymer, after fine classification, removal of foreign matter, crushing cleaning and modification treatment, to ensure low impurity content and stable physical properties.

Packaging materials: The use of impact-resistant industrial plastic packaging buckets, turnover boxes, plastic trays, sealed containers, etc., these materials have strong durability, after crushing, removal of attachments and optimization treatment, can ensure the fluidity and impact strength of recycled materials.

Industrial production waste: including injection molding, blow molding, extrusion and other processes produced in the copolymer PP scraps and defects, these raw materials are not used, stable quality, through direct recycling, purification and granulation, can ensure excellent processing adaptability and consistent product performance.

All raw materials are strictly screened and optimized to ensure low impurity content, giving RCopo PP excellent impact resistance, low temperature resistance and good processing adaptability, widely used in automotive parts, home appliance shell, industrial packaging and impact resistance structural parts and other fields.

Excellent impact resistance

Due to the copolymerization of ethylene monomer, Copo PP can still maintain good impact resistance at low temperature. Compared with Homo PP, its impact resistance is improved by more than 20%, which is suitable for high-strength demand scenarios such as car bumpers, dashboards, and home appliance housings.

Excellent chemical resistance

Copo PP has excellent chemical resistance and can resist acid, alkali, solvent and other chemical substances. Its stable molecular structure makes it widely used in chemical industry, medical equipment, food packaging and other fields, ensuring that the product can still maintain stable performance in harsh environments.

Good processing adaptability

Copo PP has excellent fluidity and low shrinkage, and is suitable for injection molding, extrusion, blow molding and other processing processes. Its processing properties make production more efficient, reduce material losses, and improve product consistency and molding accuracy.

Superior weather resistance and heat resistance

Copo PP can be used in the environment of 20°C to 100°C for a long time, with good weather resistance, suitable for outdoor facilities, auto parts and other products exposed to outdoor environment for a long time. In addition, its heat resistance makes it suitable for microwave heating of food packaging, hot water pipes and other applications.

Product Details:

Field of application

Automotive industry:

Copo PP is mainly used in car bumpers, instrument panels, door interior panels and other components, because of its excellent impact resistance and weather resistance, can effectively improve the service life of auto parts, and reduce the weight of the vehicle, improve fuel economy.

Home appliance industry:

In the field of home appliances, Copo PP is widely used in washing machine inner bucket, air conditioning shell, rice cooker shell, etc., to ensure that the product has good mechanical properties, but also has corrosion resistance, high temperature resistance and other characteristics, to extend the service life of home appliances.

Packaging industry:

Due to its excellent chemical resistance and food safety, Copo PP is used in food packaging, bottle caps, containers, etc., to ensure food safety and lightweight and durable packaging.

Medical & Daily Use:

Copo PP is non-toxic and odorless, and meets a number of food and medical safety standards. It is widely used in disposable medical devices, drug packaging, syringes and other products to ensure safety and reliability.

Performance advantage

High impact strength, excellent low temperature resistance, suitable for harsh environment applications.

Chemical corrosion resistance, can resist a variety of acid and alkali environment, improve product durability.

Good processing performance, suitable for injection molding, extrusion, blow molding and other processes, improve production efficiency.

Environmental protection and recyclable, in line with the requirements of sustainable development, reduce environmental pollution.

Production and sustainability

The production process of Copo PP optimizes energy consumption, reduces carbon emissions, and the material can be recycled, in line with the global trend of green manufacturing. With the continuous improvement of environmental regulations, more and more enterprises choose Copo PP to reduce their impact on the environment and achieve green manufacturing and sustainable development.

With its excellent impact resistance, chemical resistance, excellent processing adaptability and environmental protection characteristics, Copo PP has become an important material choice for many industries and occupies an important position in the global market.