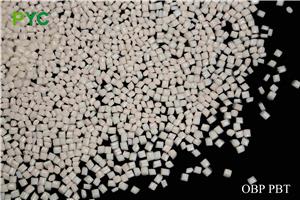

ocean bound plastic pbt

-

OBP PBT

Products (Highlights) High purity selection of raw materials to ensure excellent quality Recycle PBT (polybutylene terephthalate) from a single source with high purity, and its recycling sources include: Injection molding machine nozzle material Waste from the injection molding process, screened to ensure high purity and no additional impurities, to keep the performance of the material stable. Extrude the scraps The inclusion of unused plastic fragments generated during the production process ensures that the physical properties of recycled PBT are consistent and meet high processing requirements. Unused fiber optic connectors Unused parts from the fiber optic communications industry that ensure high stability and electrical properties of recycled PBT materials. Automotive Electrical Components Including automotive electronic control modules, sensor enclosures, etc., recycled PBT materials have excellent high temperature resistance, chemical resistance, to meet the high requirements of the automotive industry environmental adaptability. These recycled raw materials are sourced from reputable upstream manufacturers and are carefully screened and treated to ensure that there are no additional impurities and avoid affecting the physical properties of the product. No additional cleaning treatment is required to ensure that the final product has excellent mechanical properties and stability, suitable for demanding applications. 1. Marine recycled Plastics (OBP) environmental protection concept OBP PBT uses OceanBound Plastic (OBP) as the main raw material, which is derived from recycled waste within 50 kilometers of the coastline, effectively reducing Marine plastic pollution, while meeting the needs of enterprises for sustainable materials, in line with global environmental standards. 3.Excellent mechanical properties OBP PBT inherits the high strength, high toughness and excellent dimensional stability of PBT materials, and can still maintain excellent mechanical properties under high load and high-precision application scenarios, which is suitable for automotive, electronic and electrical and industrial manufacturing industries. 4.Excellent heat resistance and electrical insulation performance With excellent heat resistance, can maintain long-term stability in high temperature environment, while having low dielectric constant and high resistivity, is the ideal choice for high-performance electrical and electronic components. 5.Good chemical resistance and weather resistance It has the characteristics of acid and alkali resistance, oil resistance and solvent corrosion resistance. At the same time, it is optimized by special formula to enhance its weather resistance and anti-aging ability. It is suitable for the application of long-term exposure to harsh environment. 6.Strong processing adaptability OBP PBT is suitable for injection molding, extrusion and blow molding, with good fluidity, and can be used to manufacture complex structures and high-precision parts, improve production efficiency and reduce processing difficulty. 7.Environmentally sustainable, in line with international standards The adoption of OBP certification for recycled plastics helps to reduce plastic pollution, reduce carbon emissions, comply with global environmental regulations (such as RoHS, REACH), and is suitable for industries with strict requirements for sustainable development, such as automobiles, electronics and consumer goods. 8.Wide range of application fields Suitable for automotive electrical parts, optical fiber connectors, electronic components, home appliance shell, construction machinery parts and other industries, to meet the market demand for high performance, heat resistance, environmental protection materials.

Email Details