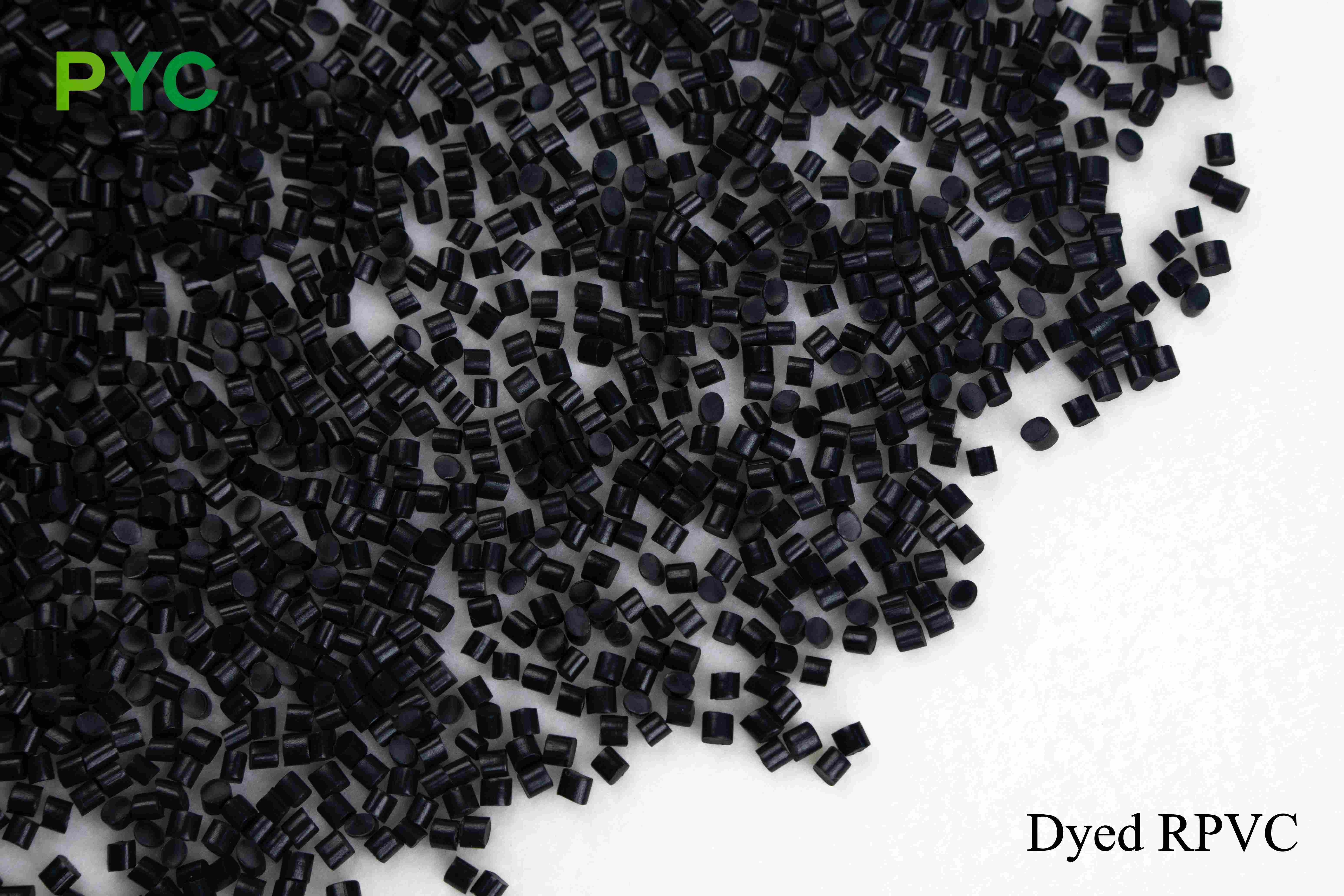

Dyed RPVC

High quality recycled raw materials

Dyed RPVC (dyed recycled polyvinyl chloride) was dyed using high quality recycled PVC as a base material, combined with advanced dyeing techniques to provide even color and outstanding physical properties. The raw materials are mainly derived from electronic waste, construction waste and industrial waste, which have been carefully selected to ensure their low impurity content and high stability, so as to ensure the color stability, aging resistance and mechanical properties of the final product.

Selected Recycling Sources

Electronic waste: from discarded electronic products, such as TV housings, electronic equipment housings, home appliance parts, etc.

PVC in electronic waste has high mechanical strength and durability, and after recycling and fine screening, it is suitable for the production of high-quality dyed recycled PVC.

Construction waste: It comes from PVC materials produced in building construction, such as pipes, window frames, door frames, etc.

After cleaning and screening treatment to ensure low impurities, construction waste can be used to produce dyed recycled PVC with high stability and adapt to the challenges of the external environment.

Industrial waste: including PVC scraps and waste generated in the industrial production process, these materials are carefully screened and cleaned to ensure high quality dyeing effect and stable physical properties.

Suitable for a variety of high-strength applications, such as auto parts, mechanical equipment shell and so on.

Strict quality inspection

During the production process, we carry out fusion finger testing (MFI) and impact testing to ensure that the products have good processability and impact resistance. Fusible finger testing ensures the stability of the material in extrusion, injection molding and other processes, while impact testing ensures its durability and reliability in application scenarios.

Excellent dyeing stability

The use of high quality pigments and advanced dyeing techniques has made Dyed RPVC dyed even and lasting color, which is not prone to fading. The color remains stable even after long-term use, and is suitable for industries that require high color consistency, such as architectural decoration, household items and electronic equipment shells.

Excellent physical properties

The product has the characteristics of high strength, impact resistance, wear resistance, etc., while maintaining good rigidity and toughness. It is suitable for industrial manufacturing, building decoration and other fields, and can meet the performance requirements of different application scenarios.

Environmental protection and sustainability

Choose high quality industrial recycled PVC, no additional cleaning, reduce energy consumption and pollution emissions. Meet environmental protection standards, help reduce carbon footprint, is the ideal choice for sustainable development, promote circular economy development.

A wide range of applications

It can be used for profiles, plates, pipes, auto parts, electronic equipment shells, etc., to meet the needs of different industries for high-performance dyed RPVC materials, with excellent processing performance and stable product quality.

Strict quality inspection

During the production process, we carry out fusion finger testing (MFI) and impact testing to ensure that the products have good processability and impact resistance. Fusible finger testing ensures the stability of the material in extrusion, injection molding and other processes, while impact testing ensures its durability and reliability in application scenarios.

Excellent dyeing stability

The use of high quality pigments and advanced dyeing techniques has made Dyed RPVC dyed even and lasting color, which is not prone to fading. The color remains stable even after long-term use, and is suitable for industries that require high color consistency, such as architectural decoration, household items and electronic equipment shells.

Excellent physical properties

The product has the characteristics of high strength, impact resistance, wear resistance, etc., while maintaining good rigidity and toughness. It is suitable for industrial manufacturing, building decoration and other fields, and can meet the performance requirements of different application scenarios.

Environmental protection and sustainability

Choose high quality industrial recycled PVC, no additional cleaning, reduce energy consumption and pollution emissions. Meet environmental protection standards, help reduce carbon footprint, is the ideal choice for sustainable development, promote circular economy development.

A wide range of applications

It can be used for profiles, plates, pipes, auto parts, electronic equipment shells, etc., to meet the needs of different industries for high-performance dyed RPVC materials, with excellent processing performance and stable product quality.

Product Details (Details)

Dyed RPVC is made from high purity, single-source industrial recycled PVC (PIR). Its main components include injection molding machine run-off, extrusion processing offcuts, sheet cutting waste, and unused profiles and tubes. These raw materials were procured directly from reputable PVC manufacturers and underwent strict screening, graded management and purification treatment to ensure a stable composition, high purity and no additional impurities, thus laying the foundation for the high performance of the final product.

In the production process, we apply efficient modification technology and strict quality control system to ensure the excellent performance of products in physical properties, color stability and processing adaptability.

Fusible finger testing (MFI) : Used to assess the fluidity of a material and ensure its stability in extrusion, injection molding and other processing processes, making it suitable for a variety of precision manufacturing needs.

Impact testing: Used to test the impact resistance of the material to ensure that the product has excellent durability and stability under high load environments, suitable for industrial applications requiring high mechanical strength.

In addition, we also carry out abrasion resistance tests on our products to ensure that they maintain good surface quality and physical properties during long-term use. All products are in line with international standards, and can provide REACH, BPA and other test reports to meet the global market's environmental protection and safety requirements.

Dyed RPVC is applied to a variety of forming processes, including extrusion, injection molding and calending, and is widely applied in a variety of fields such as tubes, profiles, decorative panels. Its excellent dyeing stability and excellent mechanical properties have made it an ideal choice for industries such as architectural decoration, household goods, electronic equipment casings and auto parts.